High-efficiency non-coking solid particle fuel gasification burner

A solid particle and fuel gasification technology, applied in the direction of solid fuel combustion, solid heating fuel, combustion methods, etc., to achieve the effects of high combustion efficiency, improved combustion efficiency, and long residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

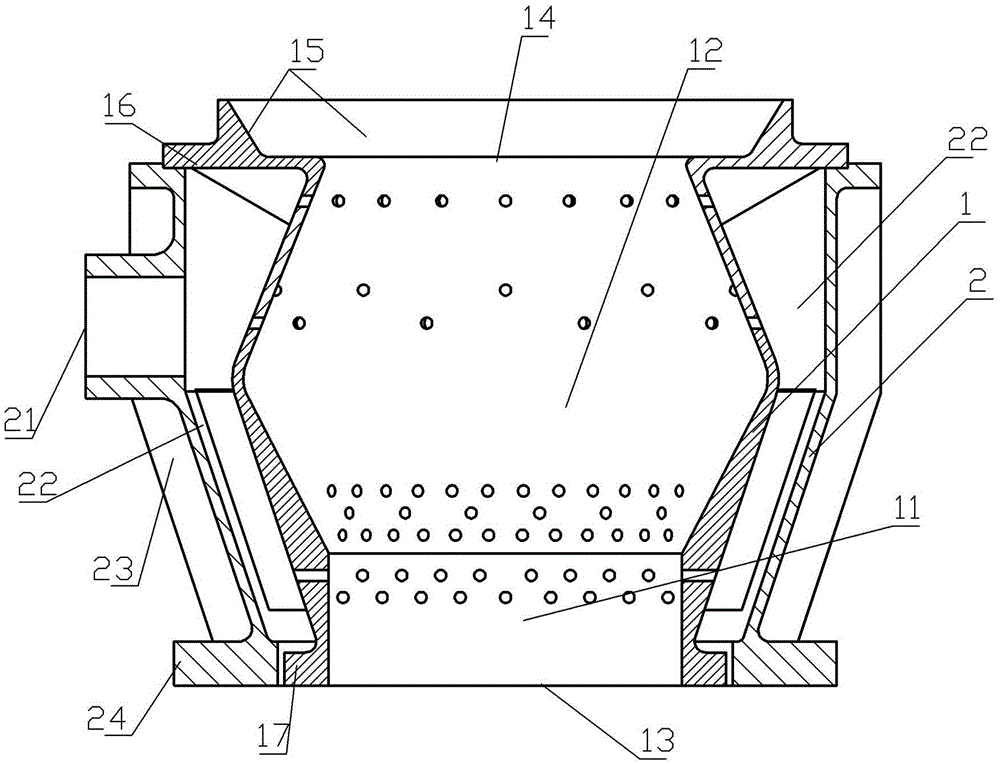

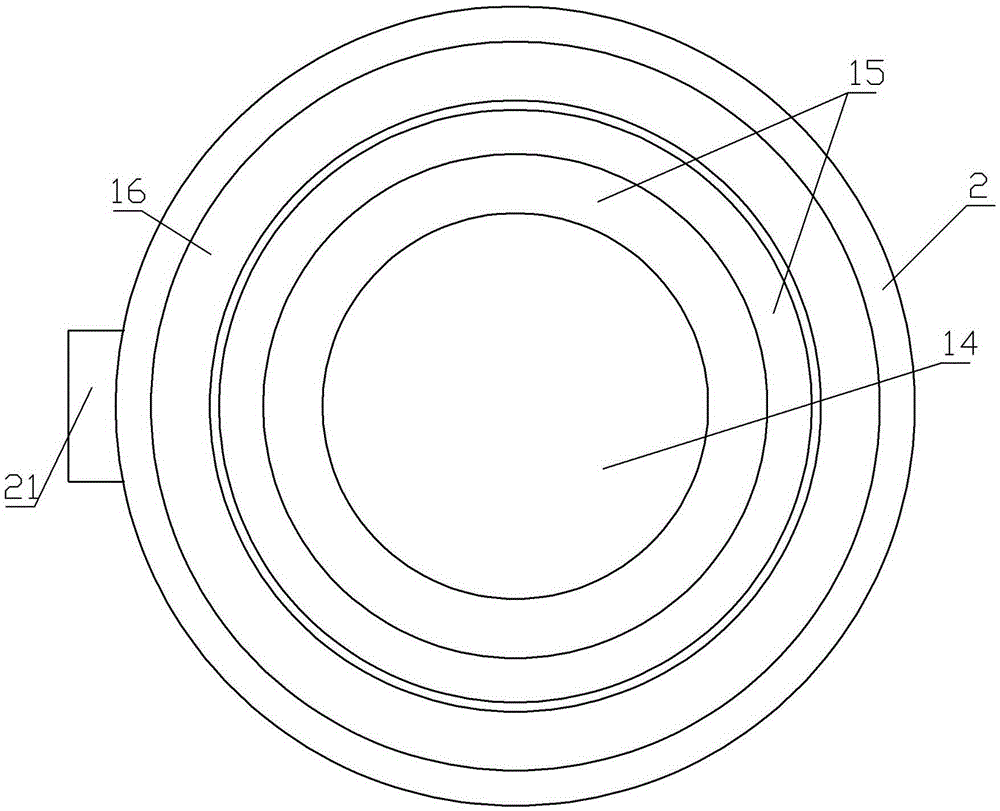

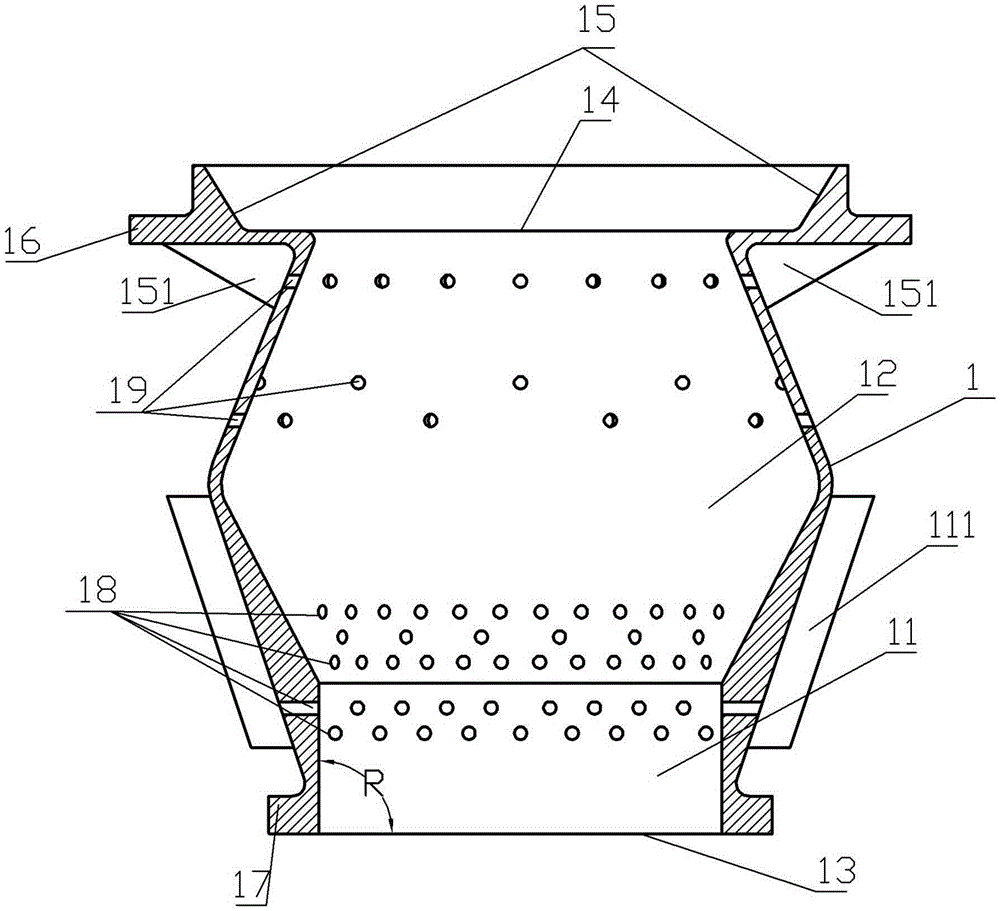

[0048] Such as Figure 1-5 Shown: a high-efficiency non-coking solid particle fuel gasification burner, which includes a gasification combustion core 1 and a core jacket 2; the gasification combustion core 1 is in the shape of a tube as a whole, that is, a through cavity with upper and lower openings inside (hollow tubular , that is, its inner cavity is a through hole); such as image 3 , 4 As shown, the inner cavity in the gasification combustion core 1 is divided into a combustion gasification chamber 11 and a gas combustion chamber 12, and the combustion gasification chamber 11 is located at the lower half of the inner cavity of the gasification combustion core 1, and the solid particle fuel (hereinafter also can be (referred to as fuel for short) is mainly burned and gasified in the combustion gasification chamber 11. The combustion gasification chamber 11 is a cylindrical or a platform-shaped cavity with a small top and a large bottom, that is, the sandwich formed by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com