Pipeline connector repair device and method

A pipeline interface and pipeline technology, which is applied in the direction of pipes/pipe joints/fittings, pipe components, mechanical equipment, etc., can solve problems such as poor sealing performance, pipeline collapse, and construction hazards, and achieve improved ring stiffness, good sealing, and construction. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

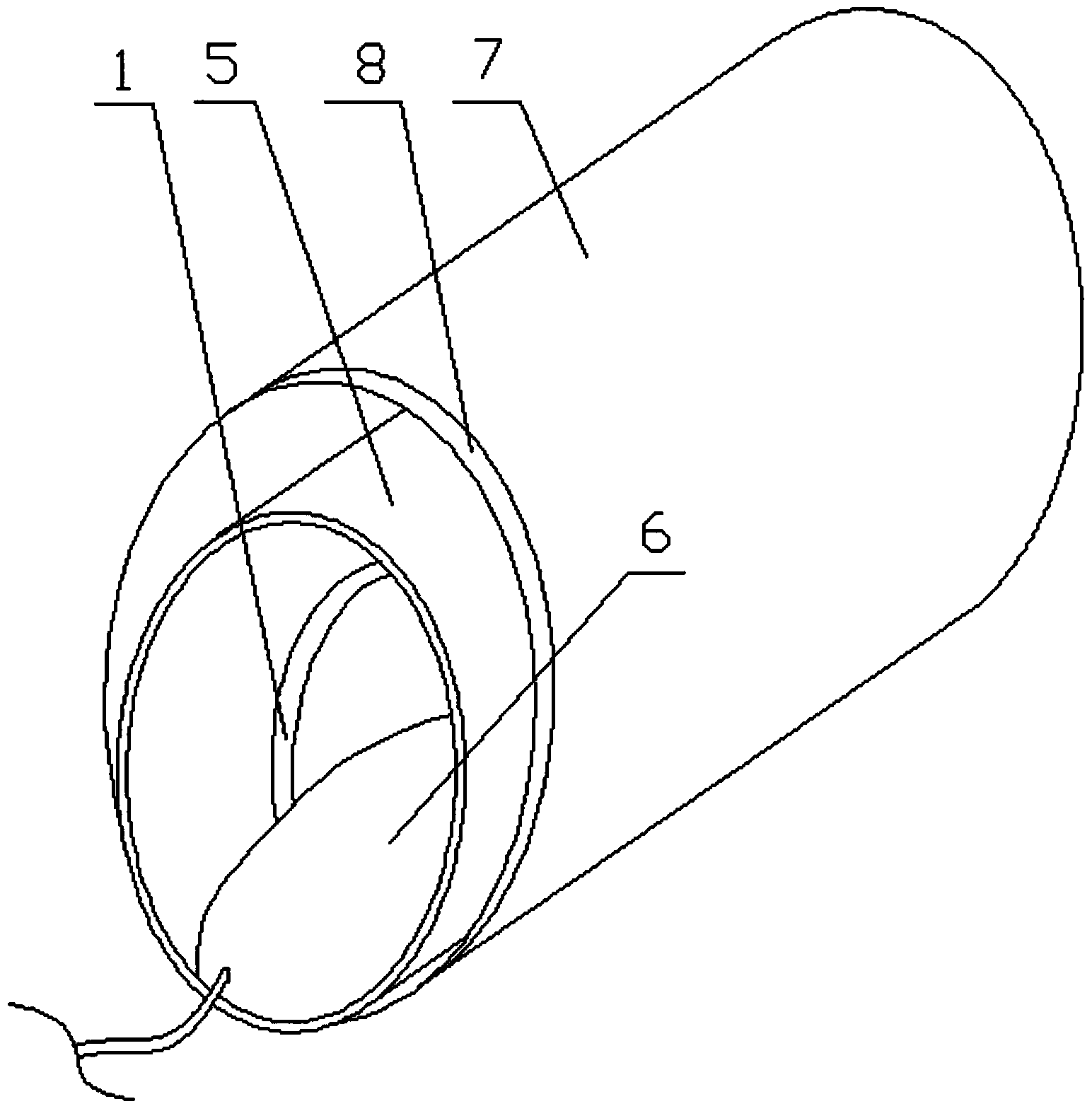

[0034] Repair devices for repairing pipe joints such as Figure 1 to Figure 2 As shown, including the reel 5 whose outer diameter size matches the inner diameter size of the pipeline 7, in this embodiment, the reel 5 is a rubber reel, and the performance of the rubber reel absorbing the foaming agent layer is better, which can prevent foaming The agent layer is separated from the roll 5 or prevents the foaming agent layer from flowing from the upper area of the roll 5 to the lower area of the roll 5 . The outer diameter of the reel 5 is smaller than the inner diameter of the pipe 7 .

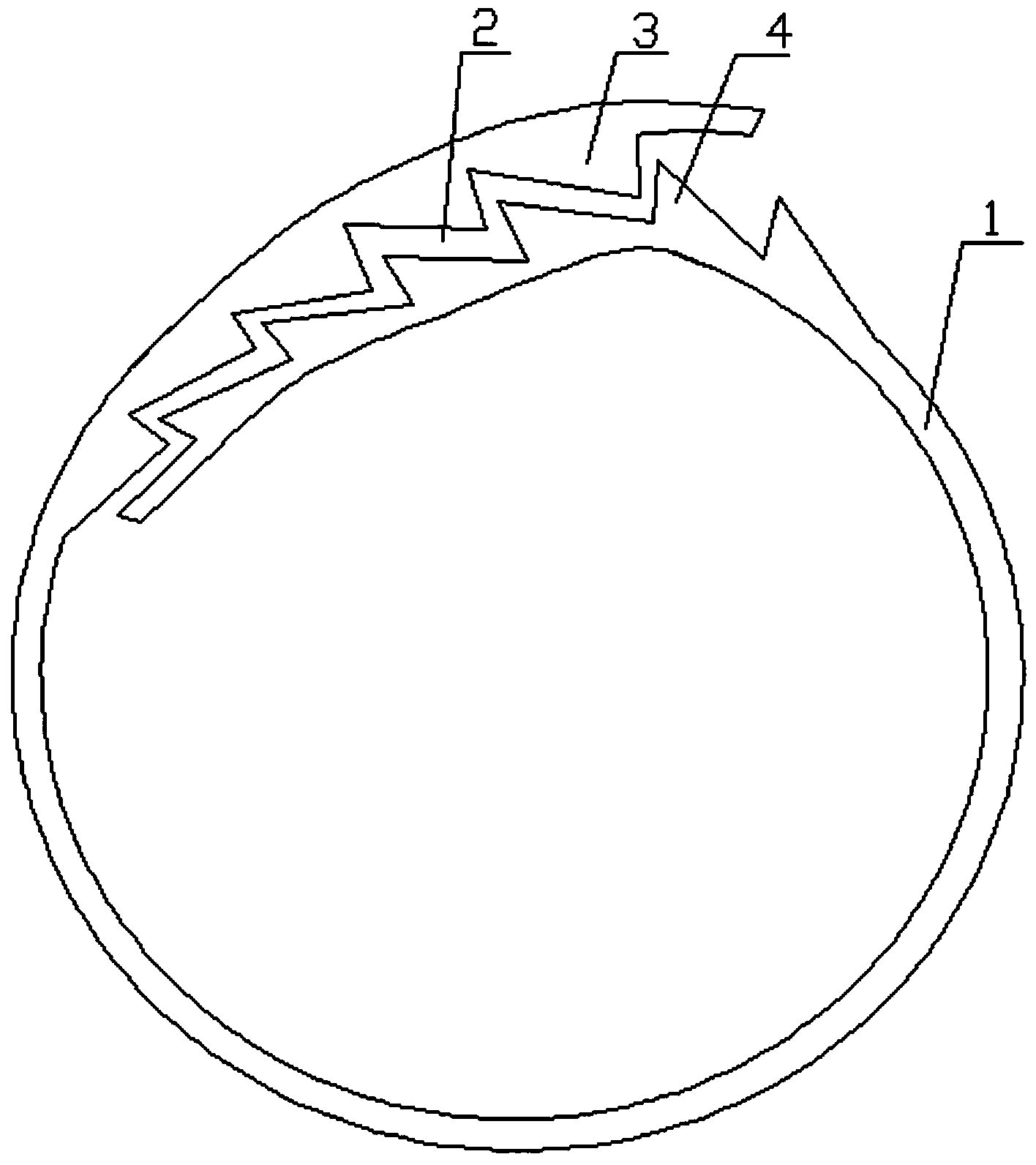

[0035] Both the first positioning latch 3 and the second positioning latch 4 are one-way latches, and they can only move in one direction after meshing.

[0036] The length of the reel 5 is between 60cm and 80cm, the outer surface of the reel 5 is provided with a foaming agent layer, the thickness of the foaming agent layer is between 0.1-0.2cm, and the foaming agent layer is a water-solubl...

Embodiment 2

[0039] The method for repairing the pipeline interface includes the following steps:

[0040] Step 1: Preparation of the repair device: Put stainless steel buckle 1 on the inner circumference of the rubber reel. The outer diameter of the rubber reel is slightly smaller than the inner diameter of the pipe 7. For example, the inner diameter of the pipe 7 is 600mm, The outer diameter is set to be slightly smaller than 600mm, for example, 580mm or 590mm or 570mm is selected. The stainless steel ring buckle 1 is formed by coiling a stainless steel strip whose length is greater than the inner diameter of the pipe 7. The left and right parts of the stainless steel strip are respectively provided with a first positioning latch 3 and a second positioning latch 4. The stainless steel strip is coiled to form an opening. 2 stainless steel ring buckle 1, and the first positioning latch 3 and the second positioning latch 4 are staggeredly engaged, and the meshing of the first positioning la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com