Rubble stone stack and reinforced soil composite embankment culvert pipe structure

A technology for reinforcing embankments and rubble piles, which is applied to the bottom layer of roads, buildings, etc., can solve problems such as difficulty in installing culverts on rubble embankments, reduce construction costs, and fall deformation, and achieve coordination of uneven settlement, improved stress state, and cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below with reference to the drawings and specific embodiments.

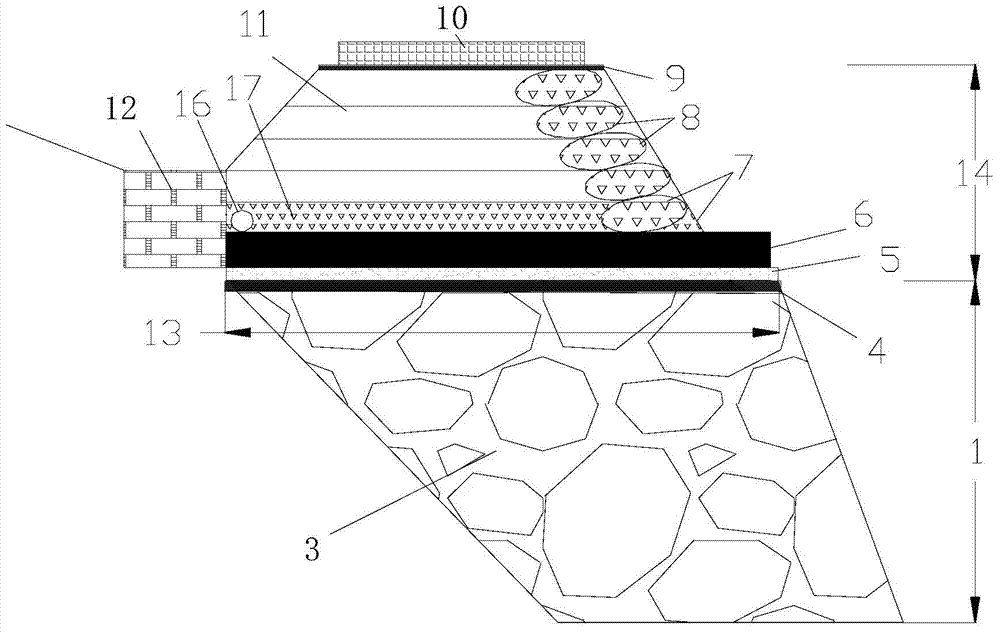

[0013] See figure 1 , The rubble embankment 3 shall be constructed according to the conventional rubble embankment, the height 1 of the rubble embankment 3 is not more than 8 meters, the top width 13 is greater than 7 meters, and the embankment surface of the rubble embankment 3 maintains an inwardly inverted embankment greater than 5% The slope rate, the upper part of the rubble embankment 3 is provided with the first impervious geotextile 4, the upper part of the first impervious geotextile 4 is provided with a cushion layer 5 made of sand and gravel, and a culvert pipe 6 is arranged on the cushion layer 5. A sinkhole 12 is provided on the side close to the natural slope, and the culvert pipe 6 is connected to the sinkhole 12. Above the culvert pipe 6 is provided a set of gravel soil 17 and a soft permeable pipe 16 placed on the side close to the natural slope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com