Coal sulfur-fixing flame accelerator and preparation method thereof

A technology of a combustion accelerator and a combination of combustion accelerators is applied in the field of coal sulfur fixation combustion accelerator and its preparation, which can solve the problems of poor sulfur fixation effect and high cost, and achieves alleviating environmental protection pressure, high use efficiency, and reduction of flue gas emissions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

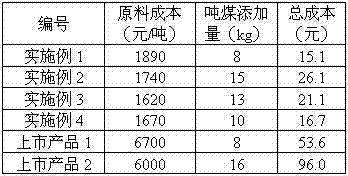

Embodiment 1

[0041] Example 1 Preparation example of coal sulfur fixation combustion accelerator

[0042] 1. Prepare materials according to the following components and mass ratio: 20 parts of alumina, 15 parts of iron oxide, 10 parts of magnesium oxide, 5 parts of silicon oxide, 8 parts of aluminum humate, 8 parts of magnesium humate, coal powder 20 parts, 3 parts of sodium hydroxide, 1 part of potassium oxide, and 1 part of calcium hydroxide.

[0043] 2. Preparation method:

[0044] (1) Mix the above components and stir evenly;

[0045] (2) Grinding the mixture obtained in step (1) into a fine powder of 160 mesh;

[0046] (3) Divide the fine powder obtained in step (2) into separate packages.

Embodiment 2~4

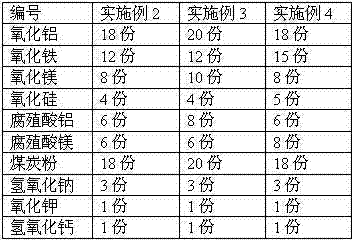

[0047] Embodiment 2~4 preparation example of coal sulfur fixation combustion accelerator

[0048] 1. Prepare materials according to the composition and mass parts proportioning in Table 1:

[0049] Table 1 Embodiment 2~4 components and proportioning

[0050]

[0051] 2. Preparation method: except that the number of meshes is different and shown in Table 2, the others are the same as in Example 1.

[0052] Table 2 Example 2~4 fine powder mesh number

[0053]

[0054] Embodiment 5~7 and comparative example 1~5

[0055] Sulfur-fixing treatment: adopt the coal-sulphur-fixing combustion accelerator prepared in Example 1, Example 2, listed product 1 or listed product 2 to carry out sulfur-fixed treatment on coal, the method is as follows:

[0056] Mix the above-mentioned coal sulfur-fixing combustion accelerator evenly into the coal before burning coal into the furnace, then add a mixture of calcium acetate and calcium hydroxide, and burn it. The mixed solution concentrati...

Embodiment 8

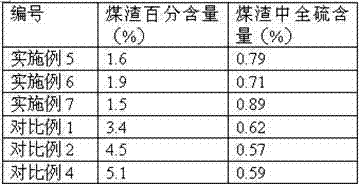

[0060]Example 8 Combustion promotion and sulfur fixation effect test

[0061] Taking the listed product 1 and the listed product 2 circulating in the market as a comparison, the percentage content of the coal slag after coal combustion in Examples 5 to 7 in the coal before combustion and the total sulfur content in the coal slag were measured.

[0062] The determination method is as follows:

[0063] 1. Collect the coal slag after combustion of Examples 5-7, Comparative Example 1, Comparative Example 2 and Comparative Example 4, and calculate the weight percentage of coal slag in the coal before combustion.

[0064] 2. Take the above-mentioned ash samples, and measure the total sulfur content in them according to the method stipulated in the national standard GB / T214 (the weight percentage of all forms of sulfur in the cinder).

[0065] The measurement results are shown in Table 4.

[0066] Table 4 Determination results of percentage content of cinder and total sulfur conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com