Method used for producing methyl acetate

A technology of methyl acetate and dimethyl ether, which is applied in the field of preparing methyl acetate through carbonylation of dimethyl ether, can solve the problems of short life, poor catalyst stability, and restricted application, and achieve the effect of prolonging life and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

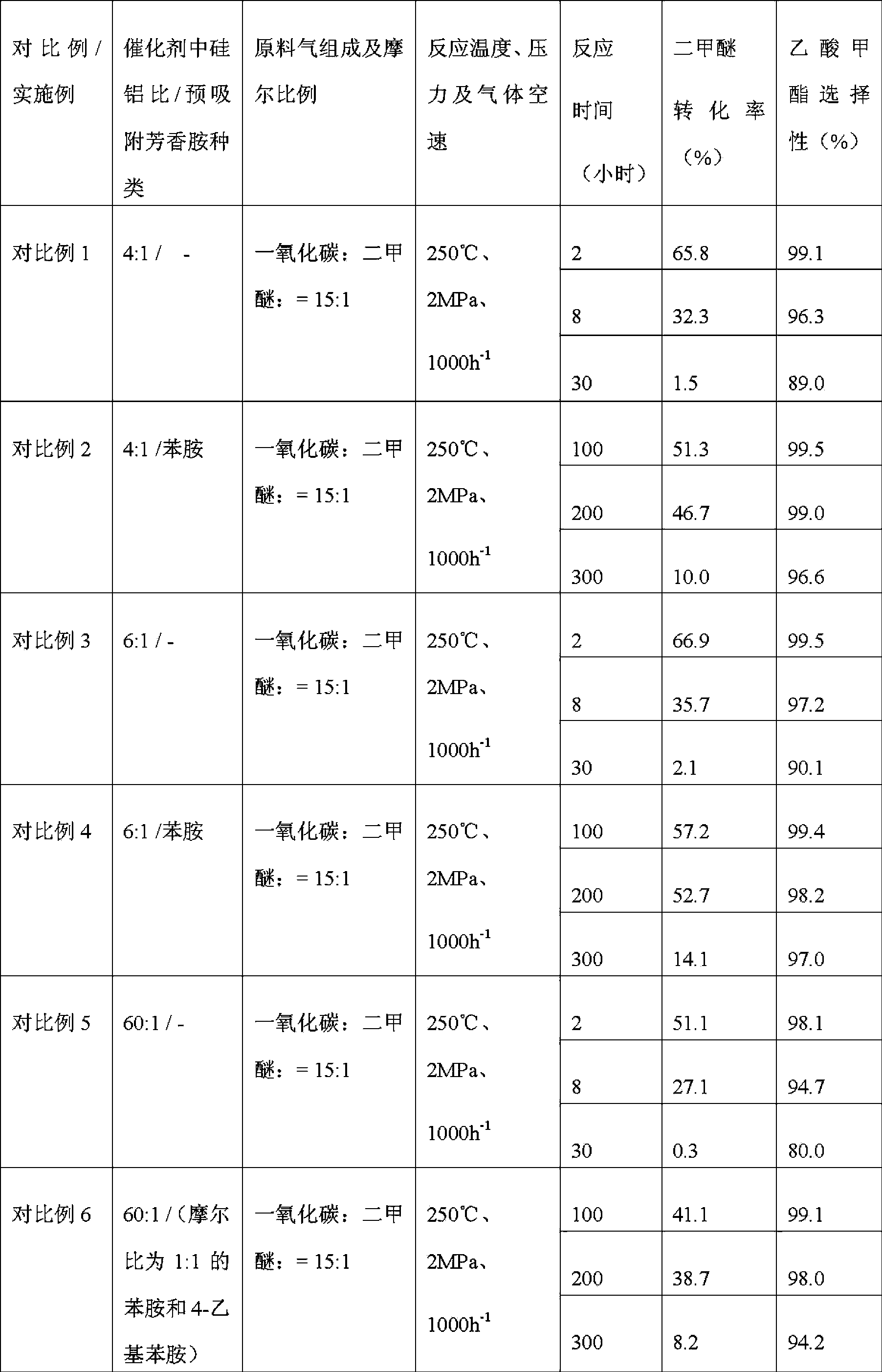

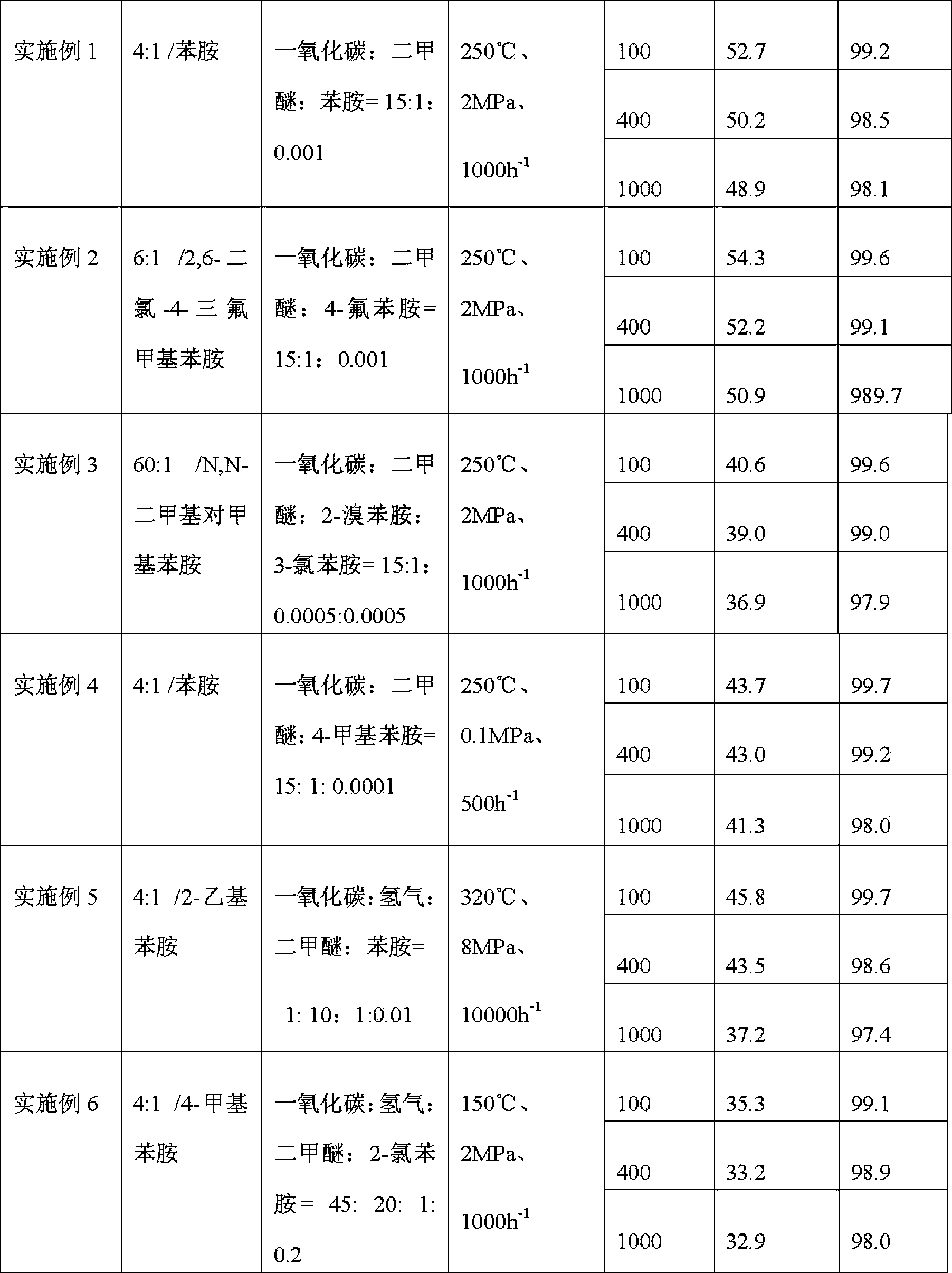

Examples

Embodiment 1

[0036]50 g of hydrogen-type mordenite with a silicon-aluminum ratio of 4:1 was calcined at 550° C. for 5 hours in an air atmosphere in a muffle furnace, and a part of the powder samples were pressed into tablets and crushed into 20-40 meshes for activity testing. Weigh 10g of the hydrogen-form mordenite sample, put it into a stainless steel reaction tube with an inner diameter of 8.5mm, activate it with nitrogen at normal pressure and 300°C for 1 hour, and then blow the aniline into the hydrogen-form mordenite by bubbling aniline liquid with nitrogen , treated for 2 hours, then purged with nitrogen for 1 hour, then lowered to 250 ° C, introduced carbon monoxide: dimethyl ether: aniline = 15: 1: 0.001, slowly boosted to reaction pressure 2MPa, controlled reaction space velocity GHSV = 1000h -1 , using gas chromatography to detect and analyze the tail gas online, and calculate the conversion rate of dimethyl ether and the selectivity of methyl acetate. The reaction results are sh...

Embodiment 2

[0038] The experimental procedure is the same as in Example 1, the silicon-aluminum ratio of the hydrogen-type mordenite is changed to 6:1, the adsorbed aniline on the catalyst is changed to 2,6-dichloro-4-trifluoromethylaniline, and the aniline in the feed gas is changed to 4-Fluoroaniline, all the other experimental steps are consistent with Example 1, and the reaction results are shown in Table 1.

Embodiment 3

[0040] The experimental procedure is the same as in Example 1, the silicon-aluminum ratio of the hydrogen-type mordenite is changed to 60:1, the adsorbed aniline on the catalyst is changed to N, N-methyl-p-methylaniline, and the aniline in the feed gas is changed to a molar ratio of 1 : 1 of 2-bromoaniline and 3-chloroaniline, all the other experimental steps are consistent with Example 1, and the reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com