Novel efficient anaerobic bioreactor

An anaerobic biological and reactor technology, applied in anaerobic digestion treatment and other directions, can solve problems such as how to evenly distribute influent water, over-deposition of activated sludge, and poor resistance to impact load of high-concentration wastewater.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

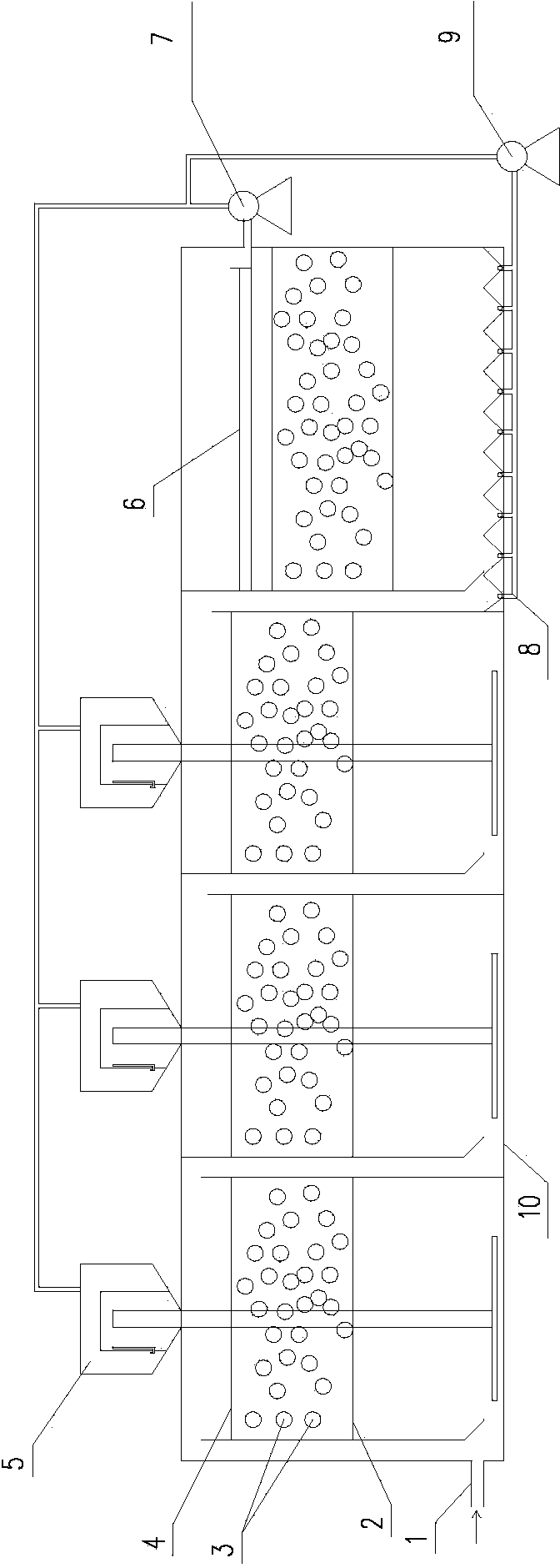

[0013] The present invention will be further described below in conjunction with accompanying drawing:

[0014] as attached figure 1 As shown, the present invention includes a reactor body 10, one side of the reactor body 10 is provided with a side water inlet water distributor 1, and sewage enters the folded plate reactor through the side water inlet water distributor 1. The lower part of each folded plate reactor in the reactor body 10 is provided with a lower supporting bed 2, and the lower supporting bed 2 is in the form of a grid plate made of a corrosion-resistant material. The lower support bed 2 is provided with a fluid biological filler layer 3, and above the fluid biological filler layer 3 is provided with an upper confinement layer 4 to prevent the loss of the fluid biological filler, and the upper confinement layer 4 is a grid plate or net made of a corrosion-resistant material. Shaped flexible packing. The top of each folded-plate reactor in the reactor body 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com