Automatic escalator speed regulating method

An automatic speed regulation and escalator technology, which is applied in the energy-saving escalator automatic speed regulation and low-cost fields, can solve the problems of being unable to sense, always not moving, always moving (that is, always sensing the situation of passengers, etc.), to reduce components damage, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

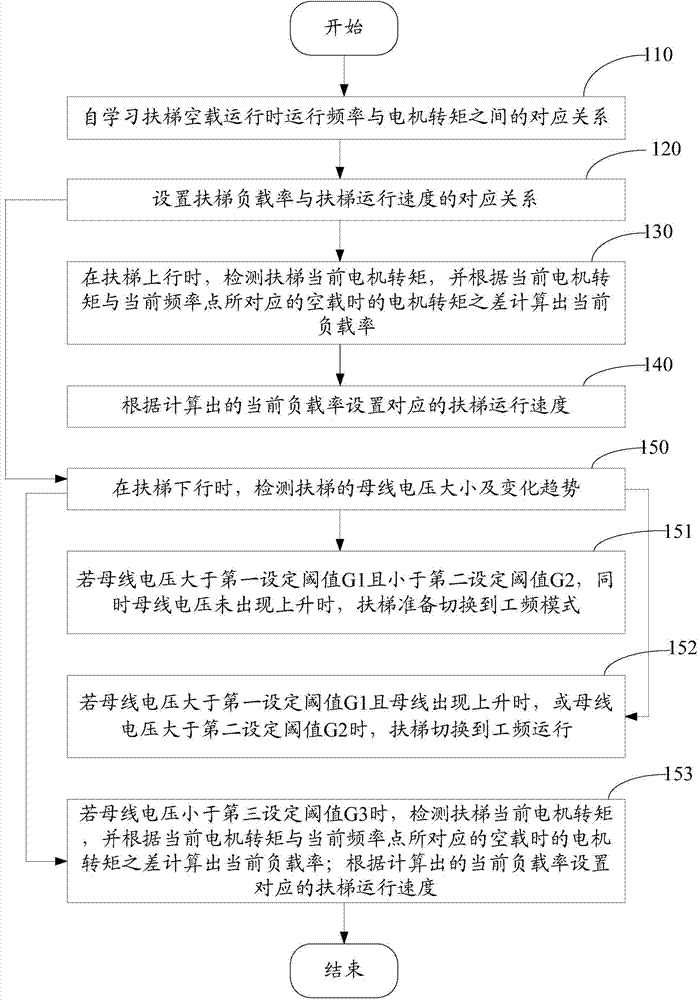

[0038] Such as figure 1 Shown is the flowchart of the automatic speed regulation method of the escalator.

[0039] A method for automatic speed regulation of an escalator, comprising the following steps:

[0040] Step S110, self-learning the corresponding relationship between the running frequency and the motor torque when the escalator is running without load.

[0041] The steps of step S110 self-learning the corresponding relationship between the running frequency and the motor torque when the escalator is running at no-load include:

[0042] ① After the escalator is powered on for the first time and runs stably at the low-speed energy-saving operating frequency f1 for the rated time, the B motor torque data of the escalator is sampled, and the B motor torque data are averaged and stored.

[0043] ② Increase the operating frequency by 0.5 Hz sequentially on the basis of the low-speed energy-saving operating frequency f1 until the escalator reaches the full-speed operating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com