Colored 3D (Three Dimensional) printing equipment using fused deposition modeling method

A technology of accumulation forming and 3D printing, which is applied in the direction of metal processing equipment, 3D object support structure, manufacturing tools, etc., can solve problems such as the inability to realize multi-color printing production, achieve rich 3D printing applications, improve work efficiency, and save coloring The effect of processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] This embodiment is used to illustrate the working principle of a color 3D printing device using a hot-melt deposition molding method.

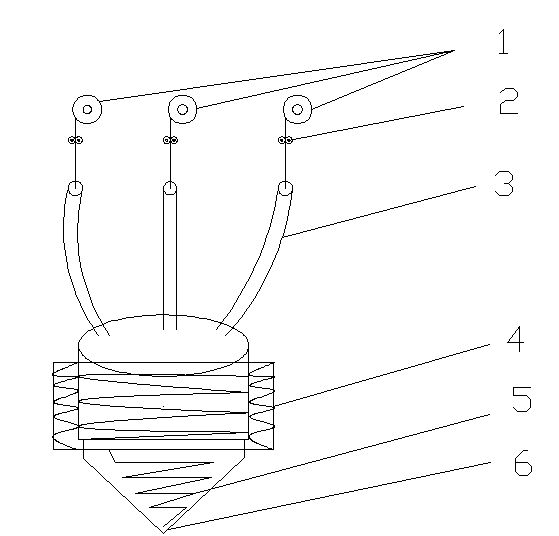

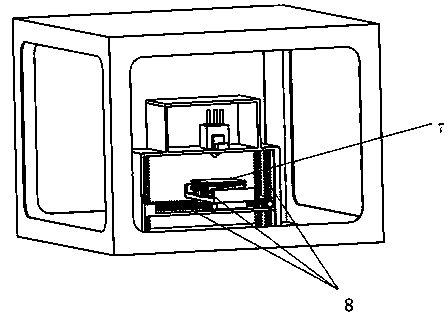

[0018] Such as figure 1 with figure 2 As shown, the FDM color 3D printing equipment implemented in the present invention mainly includes: three sets of red, yellow, and blue colors consisting of a discharge wire reel 1, a stepping motor feeder 2, and a feed conduit 3. It consists of three-color filament raw material feeding mechanism, mixing heater 4, static / dynamic pipeline mixer 5, replaceable printing nozzle 6, three-dimensional motion forming platform 7 with heating function, and equipment control system.

[0019] First, the professional software control system of the 3D printer recognizes the layered printing path data and color data of the digital model of the product, and then controls the red, green and blue three-color filaments on the feeding filament tray 1 through the stepping motor feeder 2 respectively. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com