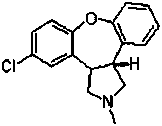

Asenapine composition and preparation method thereof

A composition and substance technology, applied in the field of asenapine composition, can solve the problems of large-scale freeze-drying equipment, long production cycle, fragility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Prescription composition:

[0036] components content Asenapine Maleate 5 copies Anhydrous Directly Compressed Lactose 20 copies Spray Dried Mannitol 52.5 copies Camphor 17.5 servings PEG6000 5 copies

[0037] Preparation:

[0038] i) Asenapine maleate is passed through a 100-mesh sieve, and camphor is pulverized through a 60-mesh sieve for subsequent use;

[0039] ii) First mix the prescribed amount of camphor with PEG6000 evenly, and then mix with the remaining ingredients in the prescription;

[0040] iii) The mixed powder is directly compressed into tablets, and the hardness is maintained at 4-5kg / cm 2 about;

[0041] iv) Place the tablet at 80°C for heat treatment;

[0042] v) After 5 hours, take it out and weigh it to confirm that the camphor is completely removed.

Embodiment 2

[0044] Prescription composition:

[0045] components content Asenapine Maleate 5 copies Anhydrous Directly Compressed Lactose 20 copies Spray Dried Mannitol 52.5 copies Camphor 17.5 servings PEG6000 5 copies

[0046] Preparation:

[0047] i) Asenapine maleate is passed through a 100-mesh sieve, and camphor is pulverized through a 60-mesh sieve for subsequent use;

[0048] ii) mixing the prescribed amount of asenapine maleate, anhydrous direct compression lactose, spray-dried mannitol and camphor, and dry granulating;

[0049] iii) Add PEG6000 to the dry granules, mix well, and press into tablets;

[0050] iv) placing the tablet under the condition of 80° C., and heat treatment;

[0051] v) After 5 hours, take it out and weigh it to confirm that the camphor is completely removed.

Embodiment 3

[0053] Prescription composition:

[0054] components content Asenapine Maleate 10 copies Anhydrous Directly Compressed Lactose 17.5 servings Spray Dried Mannitol 52.5 copies Camphor 20 copies PEG6000 5 copies

[0055] Preparation:

[0056] i) Asenapine maleate is passed through a 100-mesh sieve, and camphor is pulverized through a 60-mesh sieve for subsequent use;

[0057] ii) First mix the prescribed amount of camphor with PEG6000 evenly, and then mix with the remaining ingredients in the prescription;

[0058] iii) The mixed powder is directly compressed into tablets, and the hardness is maintained at 4-5kg / cm 2 about;

[0059] iv) Place the tablet at 80°C for heat treatment;

[0060] v) After 5 hours, take it out and weigh it to confirm that the camphor is completely removed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com