A metal vascular clip capable of directional degradation and absorption and its preparation method

A blood vessel clip and metal technology, applied in wound clips, medical science, surgery, etc., can solve the problems of clip body fracture failure, cusp potential corrosion, uncontrollable degradation, etc., and achieve satisfactory closed clip sealing effect and good biocompatibility Good performance and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The magnesium alloy ingot with a magnesium content of more than 98% is extruded into a 3 mm thick magnesium alloy plate, the extrusion ratio is 25, the extrusion temperature is 300 ° C, and the grain diameter of the formed plate is ≤ 20 μm. The formed plate is cold-rolled, and the single deformation of cold rolling is 3%. When the cumulative deformation is 25%, annealing is performed at a temperature of 300°C for 200 seconds, and then the above cold-rolling process is repeated until the thickness of the plate is 0.8mm, its grain diameter ≤ 10μm, tensile strength > 180MPa, elongation > 5%.

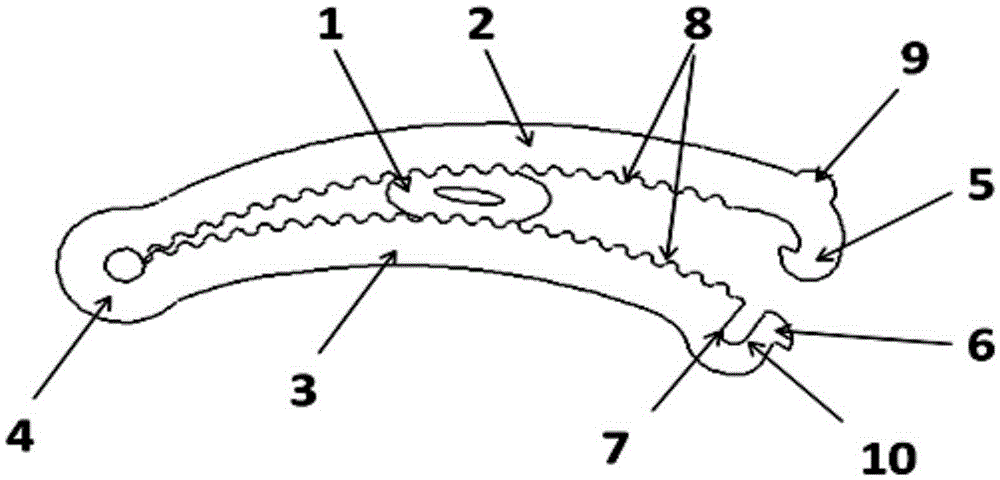

[0051] The plate obtained by the above processing steps is processed by wire cutting to obtain a blood vessel clip, and the structure is as follows figure 1 Middle blood vessel clamp upper arm 2, blood vessel clamp lower arm 3, tail O-shaped structure 4, upper arm fixing hook 5, lower arm fixing hook 6, lower arm elastic structure 7, inner sealing surface of blood vessel clamp 8, ass...

Embodiment 2

[0062] More than 99.99% of magnesium ingots are extruded into 3mm thick magnesium plates, the extrusion ratio is 25, the extrusion temperature is 300°C, and the grain diameter of the formed plates is ≤20μm, and the extruded plates are cooled Rolling, the single deformation of cold rolling is 3%, when the cumulative deformation is 25%, annealing is carried out at a temperature of 300°C and a time of 200 seconds, and then the above cold rolling process is repeated until the plate thickness is 0.8mm. Grain diameter ≤ 10μm, tensile strength > 180MPa, elongation > 5%.

[0063] The plate obtained by the above processing steps is processed by wire cutting to obtain a blood vessel clip, and the structure is as follows figure 1 Middle 2 vascular clip upper arm, 3 vascular clip lower arm, 4 tail O-shaped structure, 5 upper arm fixed hook, 6 lower arm fixed hook, 7 lower arm elastic structure, 8 inner sealing surface of vascular clip, 9 assembly upper fixed structure, 10 assembly Lower ...

Embodiment 3

[0067] More than 99.99% of magnesium ingots are extruded into 3mm thick magnesium plates, the extrusion ratio is 35, the extrusion temperature is 200°C, the grain diameter of the formed plates is ≤12μm, and the extruded plates are cooled Rolling, the single deformation of cold rolling is 5%, when the cumulative deformation is 40%, annealing is carried out at a temperature of 250 ° C for 60 seconds, and then the above cold rolling process is repeated until the thickness of the plate is 0.8mm. Grain diameter ≤ 4μm, tensile strength > 210MPa, elongation > 7%.

[0068] The plate obtained by the above processing steps is processed by wire cutting to obtain a blood vessel clip, and the structure is as follows figure 1 Middle 2 vascular clip upper arm, 3 vascular clip lower arm, 4 tail O-shaped structure, 5 upper arm fixed hook, 6 lower arm fixed hook, 7 lower arm elastic structure, 8 inner sealing surface of vascular clip, 9 assembly upper fixed structure, 10 assembly Lower fixed s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com