A gas-liquid separator and its application

A gas-liquid separator, gas separation membrane technology, applied in electrical components, electrochemical generators, degassing through filtering liquids, etc. Liquid separation does not work and other problems to avoid high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

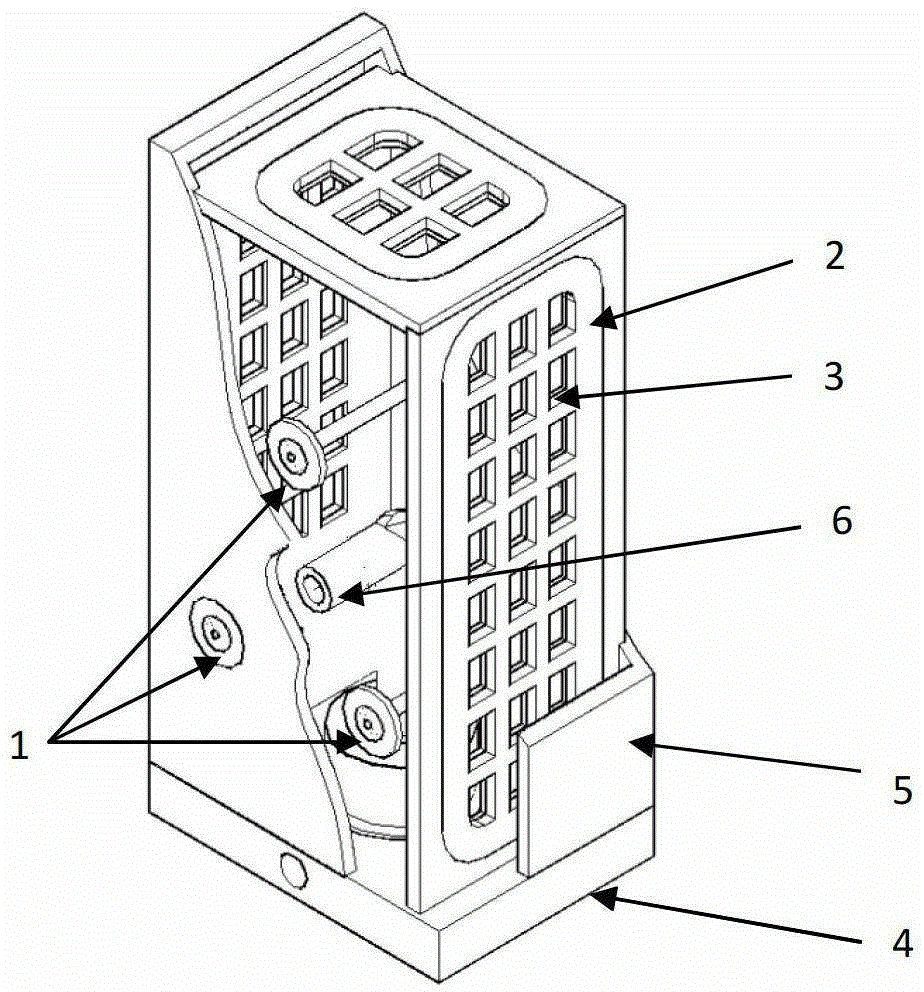

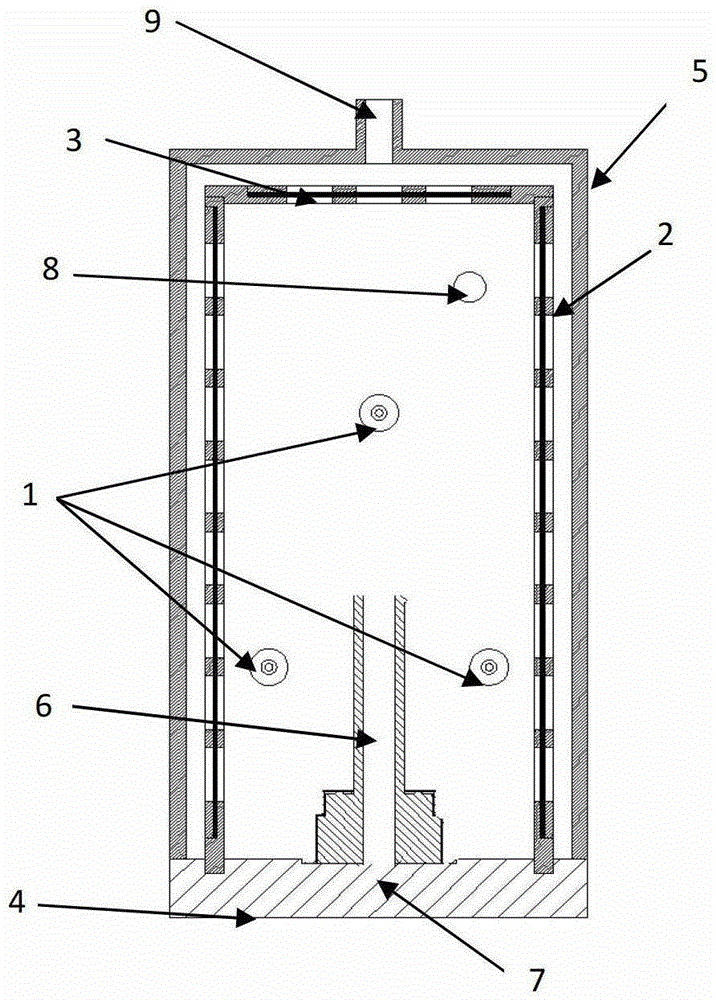

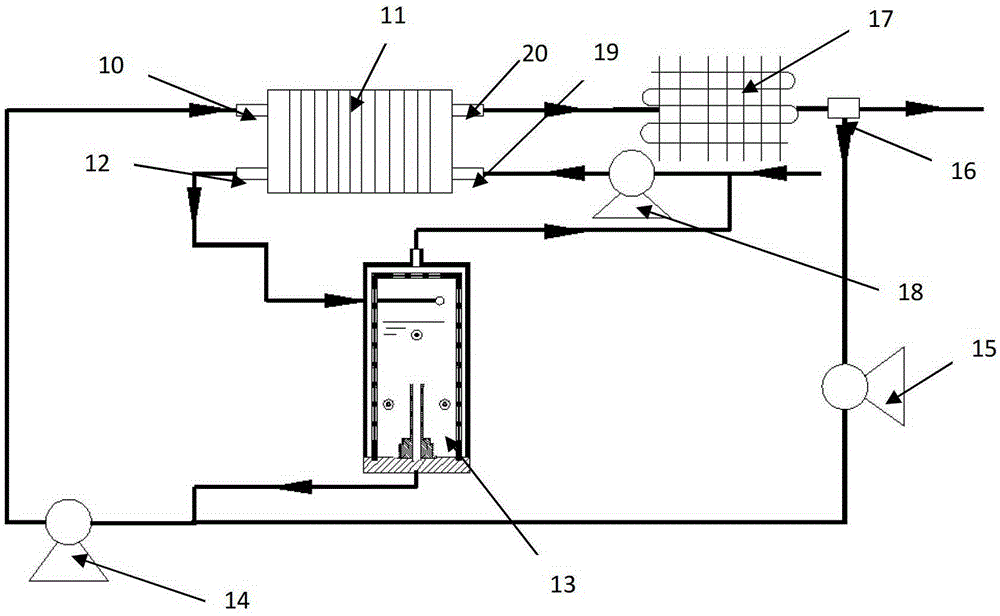

[0027] A gas-liquid separator according to the present invention includes a cuboid airtight outer shell 5, the outer shell 5 is provided with a gas separation membrane inside the fixed inner frame 2, and the inner frame 2 is fixed on the base 4 of the outer shell 5,

[0028] The part of the inner frame 2 is formed by hot pressing two layers of plastic plates with holes. The PTFE gas separation membrane 3 is sandwiched between the two layers of plastic plates. The inside of the inner frame 2 is used as a liquid storage cavity. A gas storage cavity is formed between the outer casing 5; a gas outlet 9 is provided on the outer casing 5 at the gas storage cavity; a gas-liquid mixing inlet 8 is provided on the inner frame 2;

[0029] The outer casing 5 is provided with a liquid discharge hole 7, the liquid discharge hole 7 is connected to one end of a liquid discharge pipe 6, and the other end of the liquid discharge pipe passes through the outer casing 5 and the wall of the inner fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com