Liquid level control system

A liquid level control, liquid level technology, applied in liquid level control, control/regulation system, non-electric variable control and other directions, can solve the problems of inability to filter liquid level fluctuations, inability to adjust the sensing accuracy, limited application range, etc. Novel, low manufacturing cost, good sensitivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

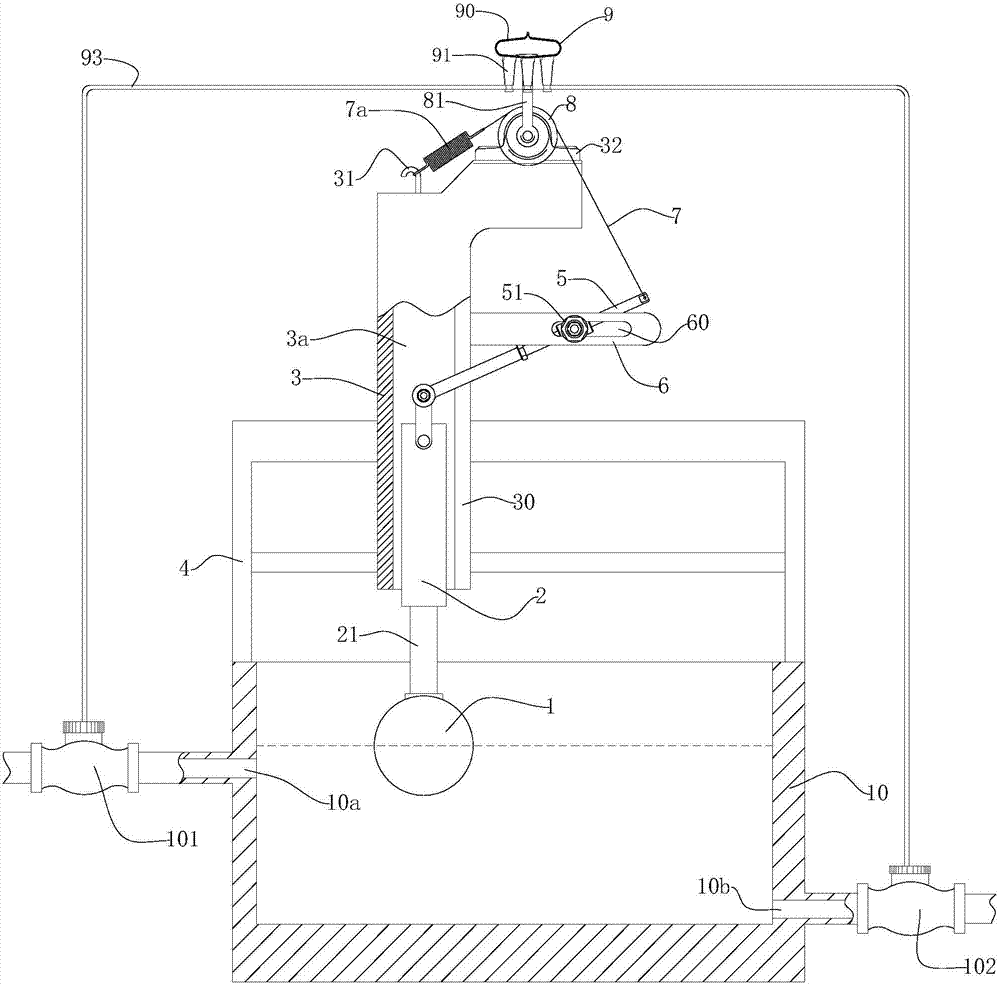

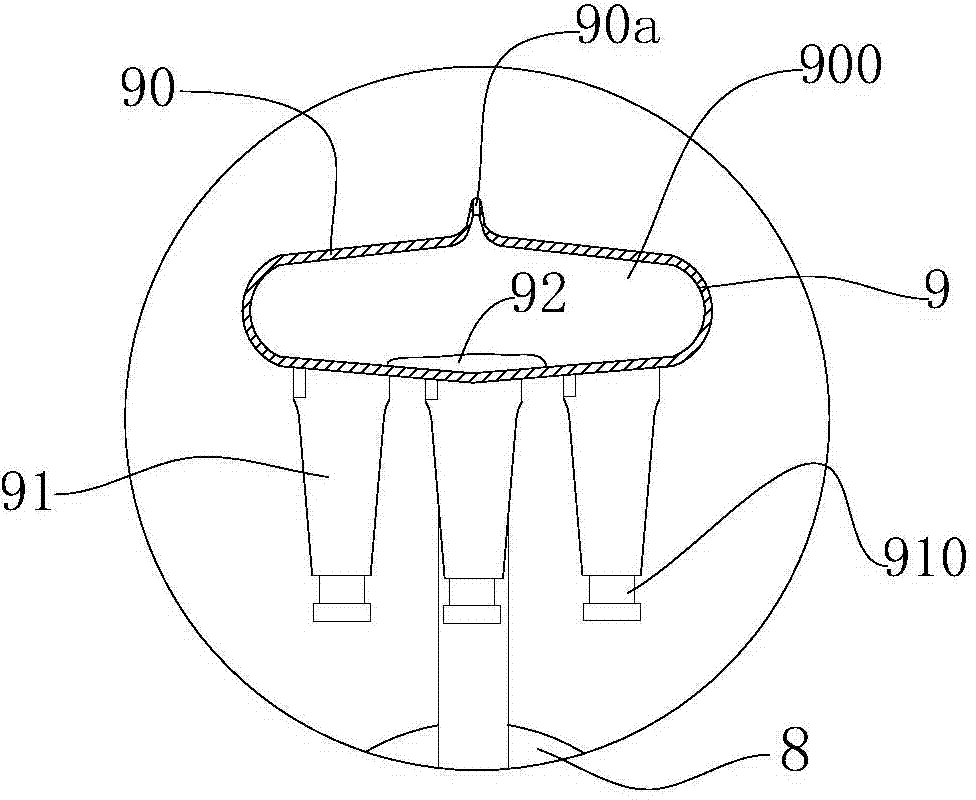

[0015] Embodiment 1: as figure 1 and figure 2 A liquid level control system is shown, the liquid level control system is installed on the pool 10 of the liquid level to be measured, the water inlet 10a is set on one side of the pool 10, the water outlet 10b is set on the other side, and the water inlet 10a is connected to the water inlet On the water pipeline, the water outlet 10b is connected to the water outlet pipeline. The liquid level control system includes a first control valve 101 connected to the water inlet pipe of the water tank 10 to be tested, a second control valve 102 connected to the water outlet pipe of the water tank 10 to be tested, and a liquid level change sensing mechanism. The mercury switch on the liquid level change sensing mechanism is respectively connected to the first control valve 101 and the second control valve 102 through the signal line 93 .

[0016] The liquid level change sensing mechanism includes a base body 3, a frame 4, a floating bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com