An Adsorption and Compression Hybrid Refrigeration and Air Conditioning System Driven by Automobile Waste Heat

A hybrid refrigeration and air-conditioning system technology, applied in the direction of machines using waste heat, refrigerators, refrigeration and liquefaction, etc., can solve the problems of unsatisfactory, low refrigeration performance coefficient, loud noise, etc., and achieve device safety, high refrigeration performance coefficient, The effect of small changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

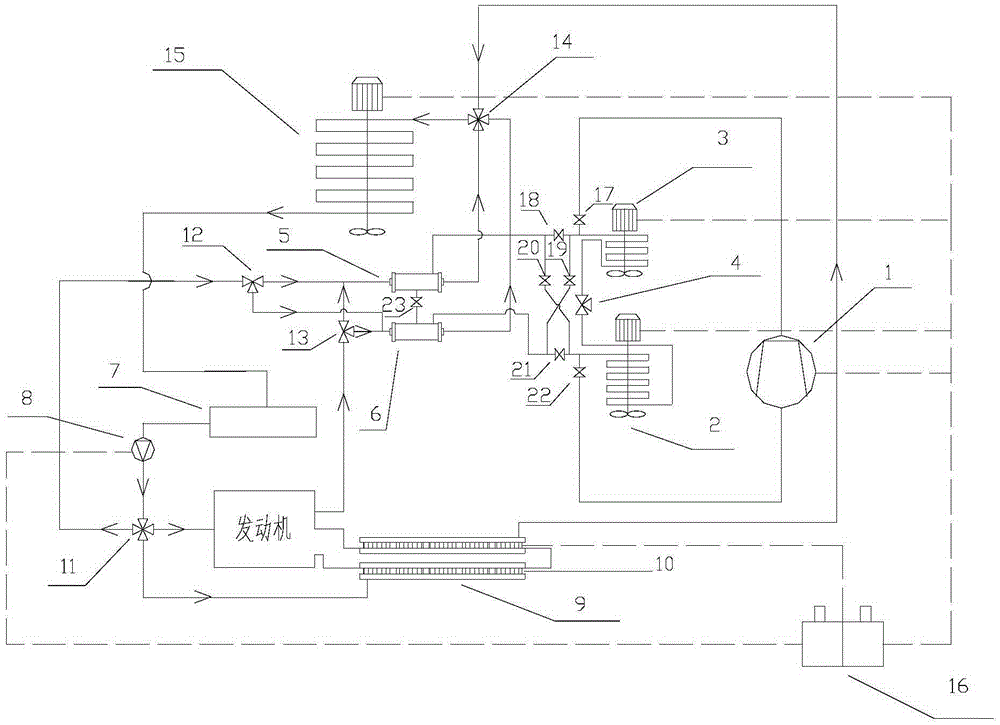

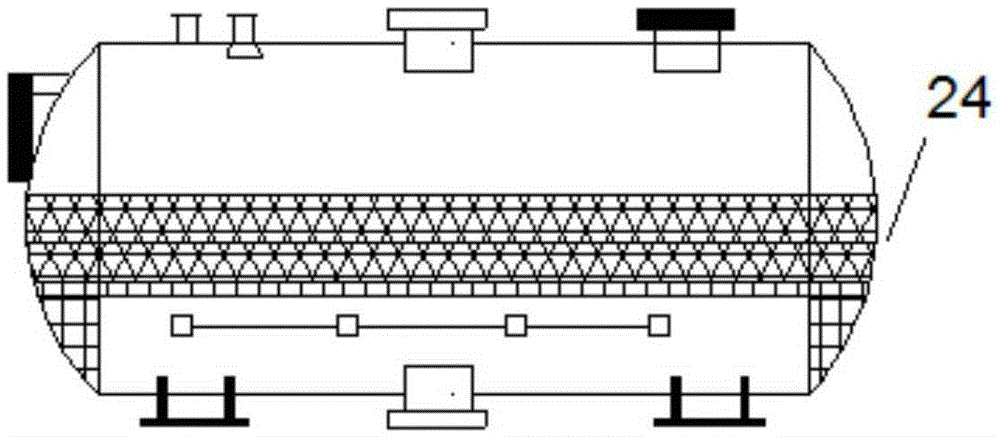

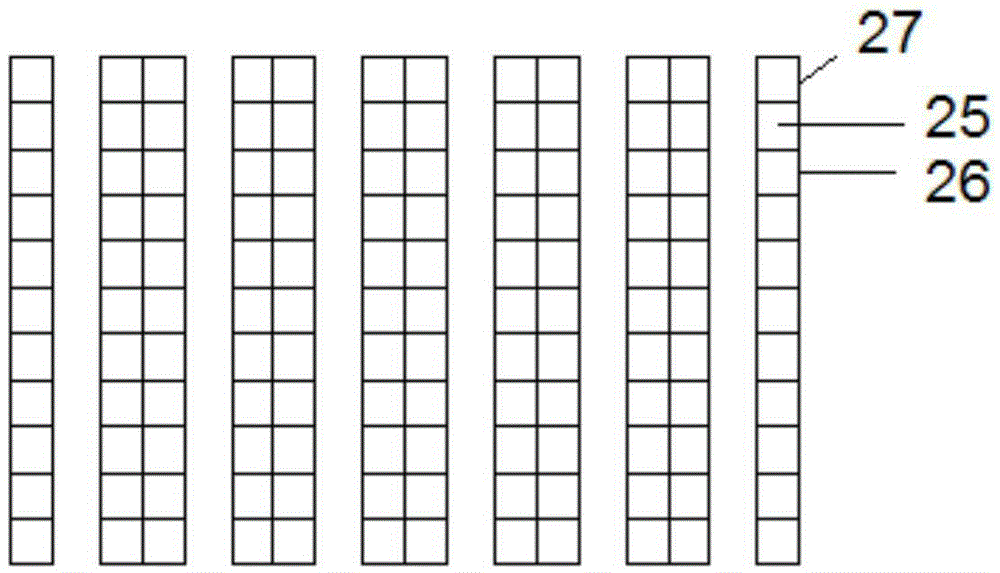

[0019] Such as figure 1 As shown, the present invention includes: compressor 1, evaporator 2, condenser 3, throttle valve 4, adsorption bed A5, adsorption bed B6, cooling water tank A7, circulating water pump 8, cooling water tank B9, thermoelectric module 10 (including the above Plate 25, bottom plate 26, see image 3 ), water separator 11, three-way regulating valve A12, three-way regulating valve B13, water collector 14, radiator 15, battery 16, 17-23 are solenoid valves (respectively solenoid valves A, C, D, E , F, B, G). The structure of the adsorption bed is figure 2 As shown, the adsorption material 24 is activated carbon inside.

[0020] The cooling water tank B9 is externally connected to the circulating water pump 8. The outlet of the circulating water pump 8 is connected to the inlet of the water separator 11, and the outlet of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com