Jacketed type corrugated pipe compensator

A technology of compensator and bellows, which is applied in expansion compensating devices for pipelines, pipe components, pipeline heating/cooling, etc. It can solve problems such as medium flow solidification, pipeline blockage, and influence on normal production, and achieve flexible compensation and linkage The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

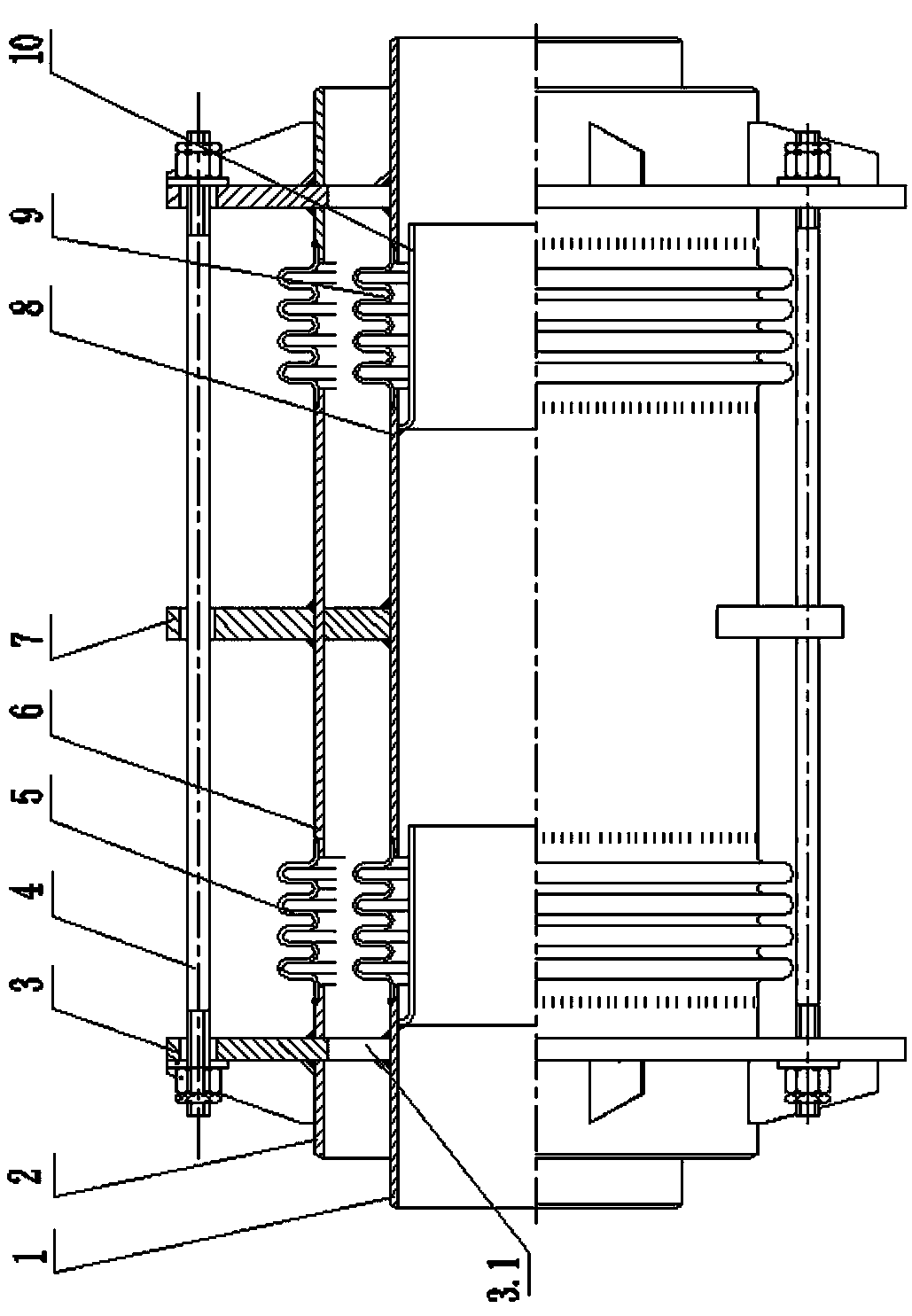

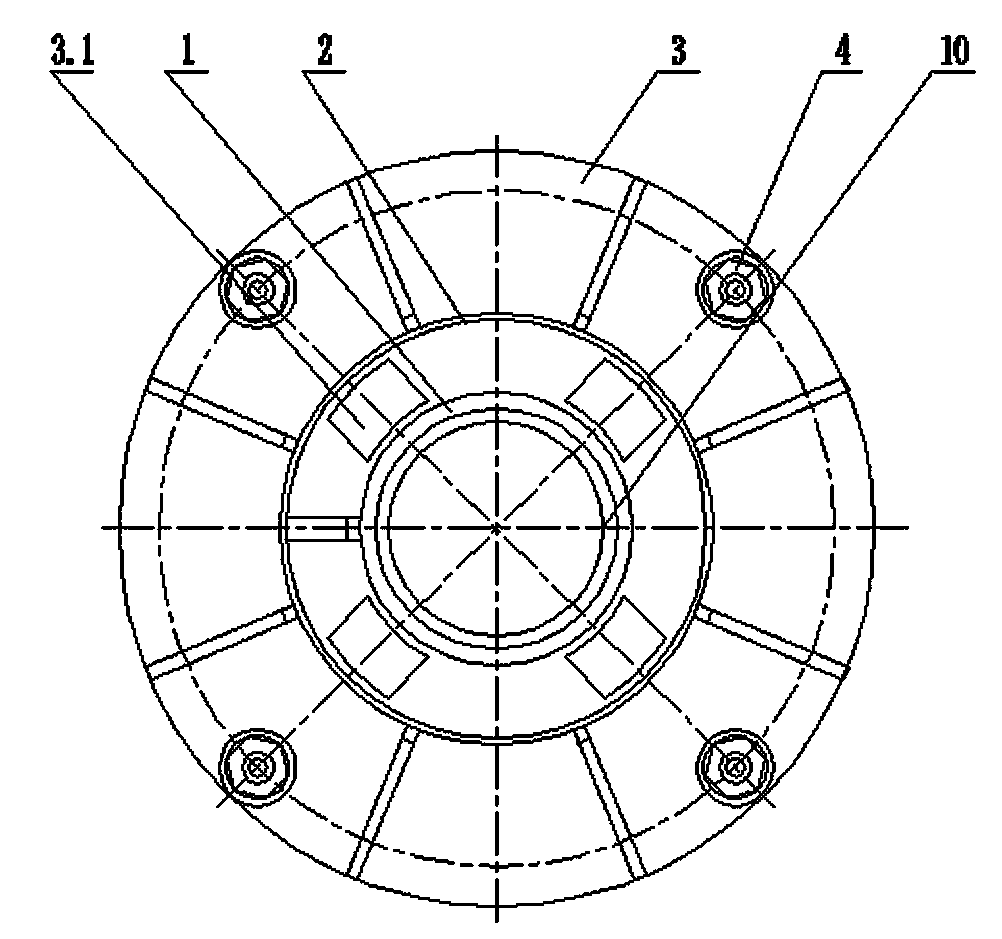

[0016] figure 1 The jacketed bellows compensator shown includes inner and outer compensators coaxially fitted together, as well as ring plate 3 , pull rod 4 and lug plate 7 for positioning and connecting the inner and outer compensators. The inner compensator is located in the middle, and it includes an inner bellows 9 and an inner nozzle 1 that are coaxially and sequentially sealed at both ends of the inner connecting pipe 8 . This embodiment is applied to steam pipelines in the petrochemical industry, with a diameter of CN1300mm and a nominal pressure of 0.6MPa. In order to further improve the flexibility of the compensation action of the inner compensator, the corrugated inner bellows 9 is U-shaped, and multi-layer thin plates are jointly rolled and formed. The inner bellows 9 with such a thin-walled multi-layer structure has good f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com