Guiding type corrugated limiter

A guide type, limiter technology, applied in the direction of pipes/pipe joints/pipes, expansion compensation devices for pipelines, mechanical equipment, etc., can solve the problems of excess flexibility and insufficient anti-rotation ability, and achieve strong compressive ability. , Significant anti-torsion effect, easy to make

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

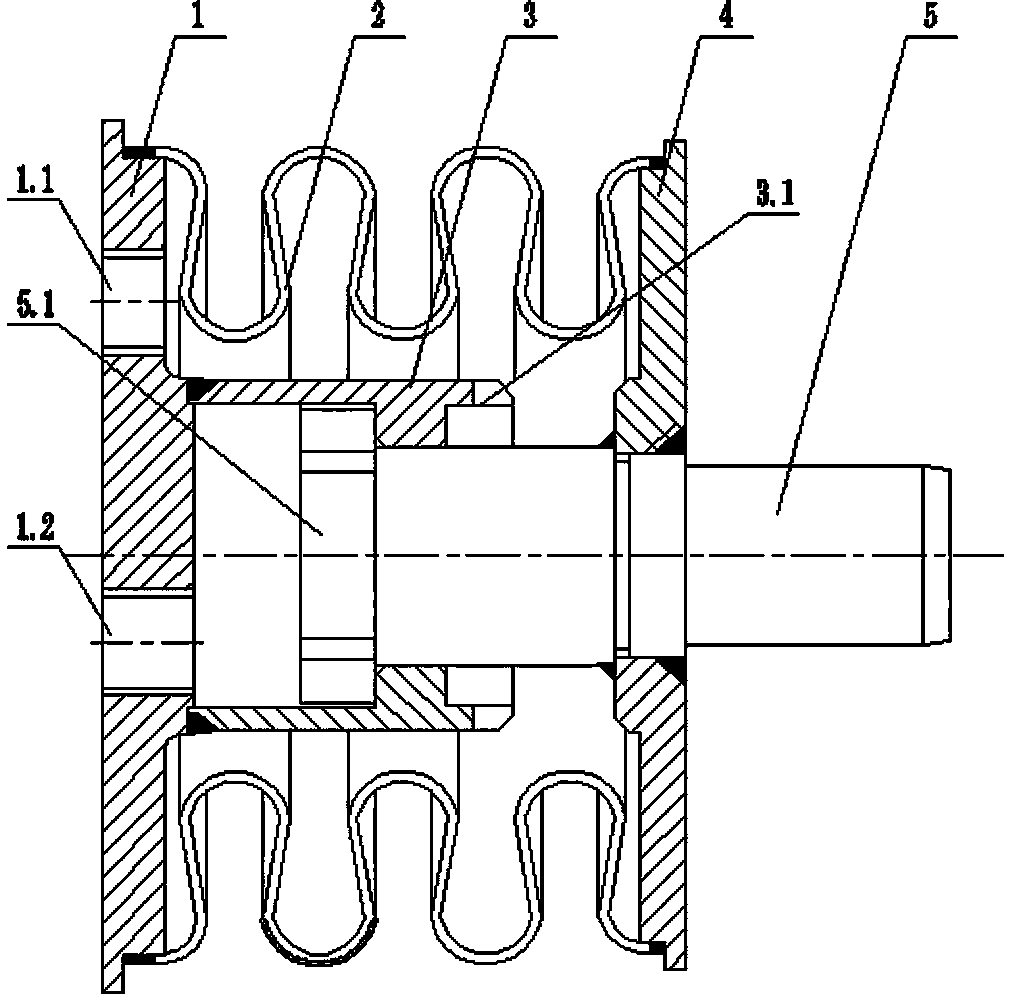

[0018] figure 1 The shown guide corrugated limiter is applied to an embodiment of a 30,000 KVA electric furnace in the iron and steel manufacturing industry. The guide sleeve 3 is a thin-walled sleeve with a built-in shoulder, and the circumference of the right port is provided with alternate gaps 3.1. The notch 3.1 is an overflow channel. In order to ensure the smooth flow of the overflow, three rectangular notches 3.1 are evenly distributed around the circumference of the right port of the guide sleeve 3 in this embodiment, and the total overflow area of the three notches 3.1 is equal to one time of the area of the outlet 1.2. . The built-in shoulder of the guide sleeve 3 is a concave-convex structure on the same circumference. During installation, the guide sleeve 3 is equipped with an external coaxial bellows 2, and a mandrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com