Ketone-removing additive for removing ketone substances from packaging card paper and application of additive

A technology of additives and paper jams, which is applied in the direction of non-polymer organic compound addition, sludge control agent addition, fiber dispersant addition, etc. It can solve the problems of incomplete removal of volatile carbonyl compounds, low removal efficiency, and long time consumption. Achieve excellent selective elimination effect, short time consumption, and the effect of eliminating ketone compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Add 100 g of water-based acrylic copolymer to 25 g of water, then add 4 g of Foamex822 defoamer, 2 g of Dispers740 lubricating dispersant and 4 g of preservative O2C and continue stirring for 0.5 h to obtain a water-dispersed coating solution containing acrylic resin. Under stirring at room temperature, slowly add ethylenediamine of 2.125g and the acetic acid of 1.275g therein, mix uniformly, obtain aqueous coating solution I, it is coated on the back of the same paper that uses in comparative example 1 (back coating ), the coating amount is 4g / m 2 . Place at room temperature for 2h.

[0049] Headspace-gas chromatography was used to detect the total amount of volatile organic compounds in the above-mentioned packaging paper according to the YC / T207-2006 standard.

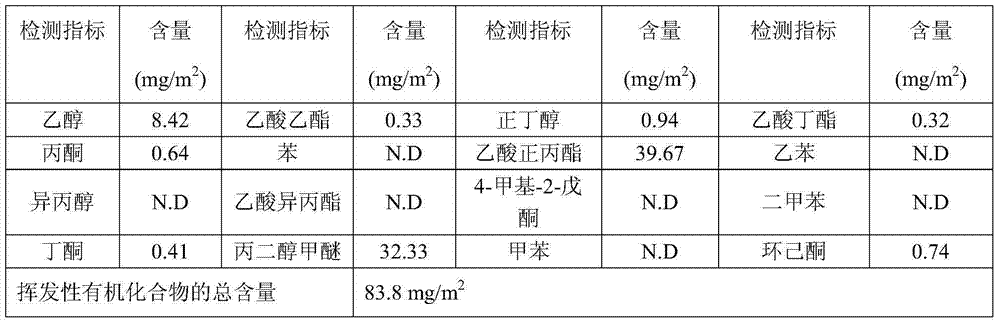

[0050] Content of volatile organic compounds VOCs in the cardboard after the aqueous coating liquid of table 4 coating embodiment 1

[0051]

[0052]

[0053] Table 5 Comparison of the content of ket...

Embodiment 2

[0058] Except that the ethylenediamine of 2.125g added in embodiment 1 is changed into propylenediamine of 2.125g, the acetic acid of 1.275g is changed into the mixture of acetic acid of 0.85g and 0.425g propionic acid, according to the same method of embodiment 1, The aqueous coating liquid II was obtained, and it was coated on the back of the same paper as that used in Comparative Example 1 (back coating), and the coating amount was 2 g / m 2 , placed at room temperature for 3h.

[0059] Headspace-gas chromatography was used to detect the total amount of volatile organic compounds in the above-mentioned packaging paper according to the YC / T207-2006 standard, and the results are shown in Table 6.

[0060] Table 6 Content of ketones in cardboard base paper and cardboard coated with water-based coating solution II

[0061]

[0062] As can be seen from Table 6, the removal efficiency of embodiment 2 to acetone is 56.5%, and the removal efficiency to methyl ethyl ketone and cyc...

Embodiment 3

[0064] Except that the ethylenediamine of 2.125g added in embodiment 1 is replaced by ethylenediamine of 0.3g and cyclohexanediamine of 0.3g, the acetic acid of 1.275g is replaced by the mixture of acetic acid of 0.4g, according to embodiment 1 same method, obtain the aqueous coating solution III, and apply it on the back of the same paper as that used in Comparative Example 1 (back coating), and the coating amount is 6g / m 2 , placed at room temperature for 2h.

[0065] Headspace-gas chromatography was used to detect the total amount of volatile organic compounds in the above-mentioned packaging paper according to the YC / T207-2006 standard, and the results are shown in Table 7.

[0066] Table 7 Contents of ketones in cardboard base paper and cardboard coated with water-based coating solution Ⅲ

[0067]

[0068] As can be seen from Table 7, the removal rate of embodiment 3 to acetone is 71.4%, and the removal rates to butanone and cyclohexanone are 100% and 100% respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com