Novel rubidium-potassium separating extracting agent and separating method

An extraction and solvent oil technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of high price and low single-stage extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

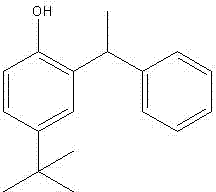

[0008] At 20°C, Rb in the brine feed solution + =100mg / L, K + =1g / L. Use 4-methyl-2-(α-methylbenzyl)phenol as the extractant, D60 solvent oil as the diluent, the concentration of the extractant is 0.5mol / L, extract the organic phase:water phase (O / A)=3:1 , the alkalinity of the feed liquid is controlled to be 0.20 mol / L sodium hydroxide concentration, the extraction time is 2 minutes, the extraction rate of rubidium after primary extraction is 87.08%, the extraction rate of potassium is 9.38%, and the separation coefficient of rubidium and potassium is 41.40. The organic phase loaded with rubidium is back-extracted with 1.5mol / L hydrochloric acid solution. Compared with O / A=5:1, the stripping rate of rubidium reaches 85%, and the stripping rate of potassium is greater than 95%. The concentrations of rubidium and potassium in the medium are Rb + =123.36mg / L, K + =148.67mg / L. After one extraction and stripping, the recovery rate of rubidium was 74.02%.

example 2

[0010] At 20°C, Rb in the brine feed solution + =1g / L, K + =10g / L. Use D80 solvent oil as the diluent, 4-methyl-2-(α-methylbenzyl)phenol as the extractant, the concentration of the extractant is 0.6 mol / L, the extraction ratio O / A=2.5:1, the concentration of sodium hydroxide 0.20 mol / L, extraction for 2 minutes: the single-stage extraction rate of rubidium is 86%, the extraction rate of potassium is 9.71%, and the separation coefficient of rubidium and potassium is 33.45. Then the organic phase loaded with rubidium is back-extracted with 2.0mol / L hydrochloric acid solution. Compared with O / A=5:1, the stripping rate of rubidium reaches 85%. The concentration of rubidium and potassium in the stripping solution is Rb + =1.34g / L,K + =1.86g / L.

example 3

[0012] At 20°C, Rb in the brine feed solution + =6g / L,K + =60g / L. Use D100 solvent oil as the diluent, 4-methyl-2-(α-methylbenzyl)phenol as the extractant, the concentration of the extractant is 1.0 mol / L, the extraction phase O / A=3:1, the concentration of sodium hydroxide 0.30 mol / L, extracted for two minutes, after primary extraction: the extraction rate of rubidium was 85.68%, the extraction rate of potassium was 15.79%, and the separation coefficient of rubidium and potassium was 31.92. Then the organic phase loaded with rubidium is back-extracted with 3.0mol / L hydrochloric acid solution. Compared with O / A=5:1, the stripping rate of rubidium reaches 85%. The concentration of rubidium and potassium in the stripping solution is Rb + =7.30g / L,K + =15.01g / L.

[0013] process such as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com