EPDM (Ethylene-Propylene-Diene Monomer) rubber composition and preparation method thereof

A technology of EPDM rubber and its composition, which is applied in the field of rubber, can solve the problems that have not been taken into account, that heat cannot be quickly dispersed, and achieve the effects of saving product costs, simple and practical processing technology, and overcoming hardening and brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

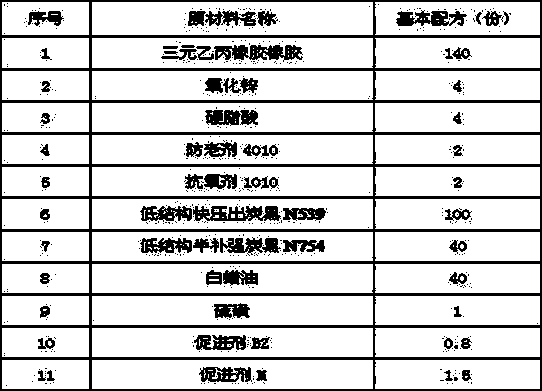

[0024]

[0025] Mixing and processing according to the raw materials and dosage in the listed ratio: rubber, raw material weighing→rubber masticating→banbury mixing and feeding→one-stage kneading and unloading→storage and cooling→second-stage kneading and vulcanization→vulcanized rubber sheets→cutting according to standards Take a sample→do a test test.

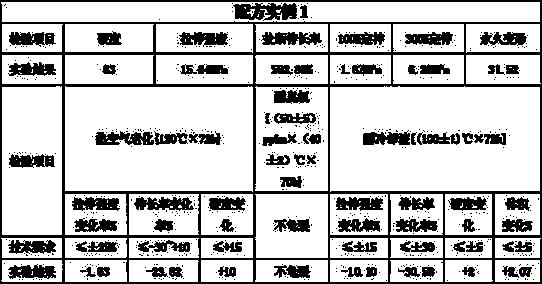

[0026] Below is embodiment 1 EPDM performance testing result:

[0027]

Embodiment 2

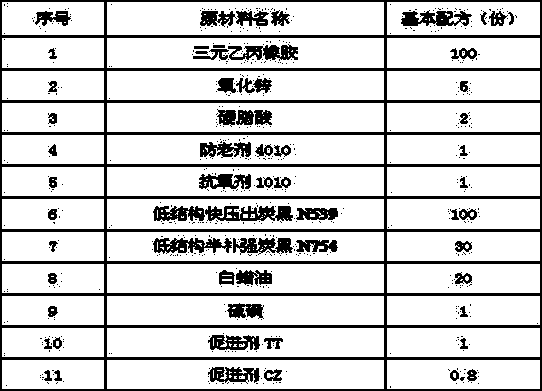

[0030]

[0031] Mixing and processing according to the raw materials and dosage in the listed ratio: rubber, raw material weighing→rubber masticating→banbury mixing and feeding→one-stage kneading and unloading→storage and cooling→second-stage kneading and vulcanization→vulcanized rubber sheets→cutting according to standards Take a sample→do a test test.

[0032] Below is embodiment 2 EPDM performance test results:

[0033]

Embodiment 3

[0036]

[0037] Mixing and processing according to the raw materials and dosage in the listed ratio: rubber, raw material weighing→rubber masticating→banbury mixing and feeding→one-stage kneading and unloading→storage and cooling→second-stage kneading and vulcanization→vulcanized rubber sheets→cutting according to standards Take a sample→do a test test.

[0038] Below is embodiment 3 EPDM performance testing results:

[0039]

[0040] Through the analysis of the results of the above several groups of tests, the EPDM formula of this invention can meet the standard requirements of GB 18948, and has high practical value, that is, it can meet the environmental and environmental conditions of the vulcanized product at 100°C-150°C. It can be used for a long time at -20°C, and at the same time, it can also meet the tensile properties (strength and elongation at break) of the vulcanized rubber to meet the production needs of the product. Thereby embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com