Production formula of silane crosslinked polyethylene

A production formula and silane cross-linking technology, applied in conductors, electrical components, circuits, etc., can solve the problems of insufficient harmful effects, obvious effects of copper damage, and fast aging of cables, etc., to achieve inhibition of catalytic aging, reasonable and convenient material matching The effect of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

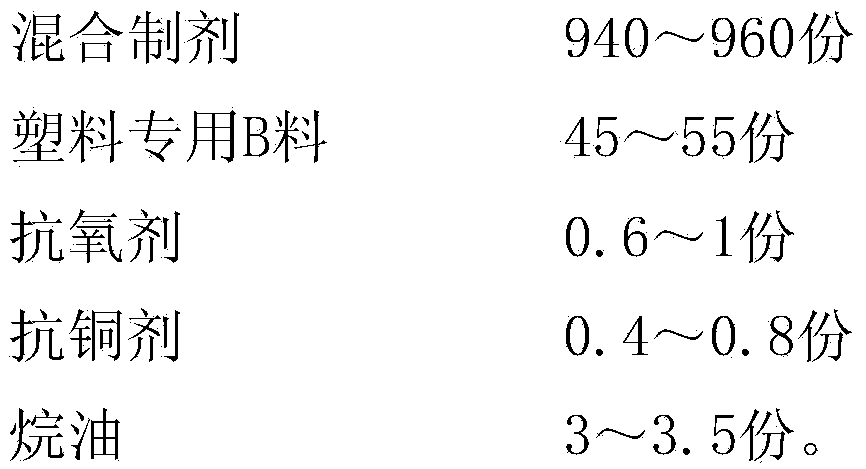

[0021] A production formula of silane cross-linked polyethylene, the formula includes mixed preparation, special B material for plastics, antioxidant, anti-copper agent and alkane oil, the parts by weight of each component are as follows:

[0022]

[0023] The mixed preparation is prepared by mixing linear low-density polyethylene, low-density polyethylene and high-pressure polyethylene in a ratio of 5:4:10.

Embodiment 2

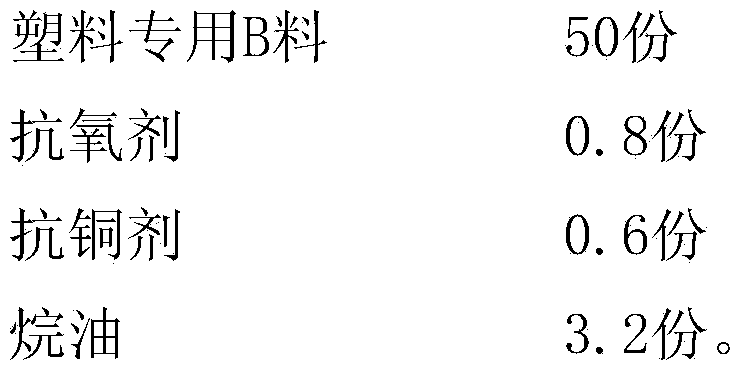

[0025] A production formula of silane cross-linked polyethylene, the formula includes mixed preparation, special B material for plastics, antioxidant, anti-copper agent and alkane oil, the parts by weight of each component are as follows:

[0026]

[0027] The mixed preparation is prepared by mixing linear low-density polyethylene, low-density polyethylene and high-pressure polyethylene in a ratio of 5:4:10.

Embodiment 3

[0029] A production formula of silane cross-linked polyethylene, the formula includes mixed preparation, special B material for plastics, antioxidant, anti-copper agent and alkane oil, the parts by weight of each component are as follows:

[0030]

[0031] The mixed preparation is prepared by mixing linear low-density polyethylene, low-density polyethylene and high-pressure polyethylene in a ratio of 5:4:10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com