Formula of 70 DEG C cable sheath

A cable sheath and formula technology, applied in the field of 70℃ PVC cable sheath formula, can solve the problems of inability to protect the cable conductor, low tensile strength of the sheath, short service life, etc., to achieve improved toughness and low manufacturing cost , Material collocation reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

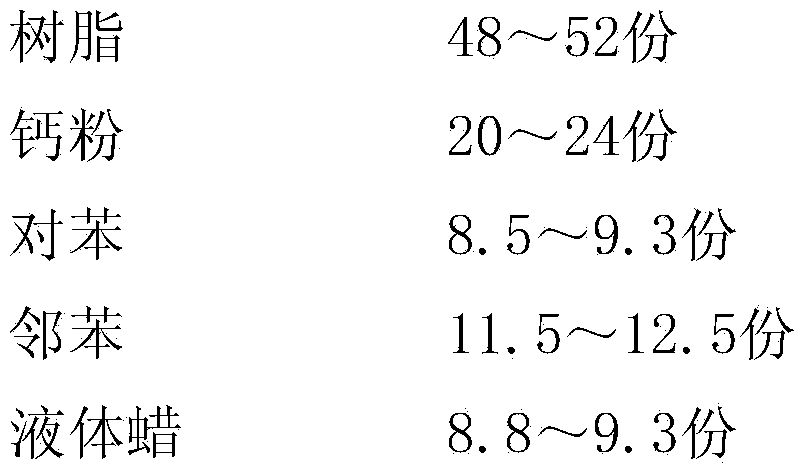

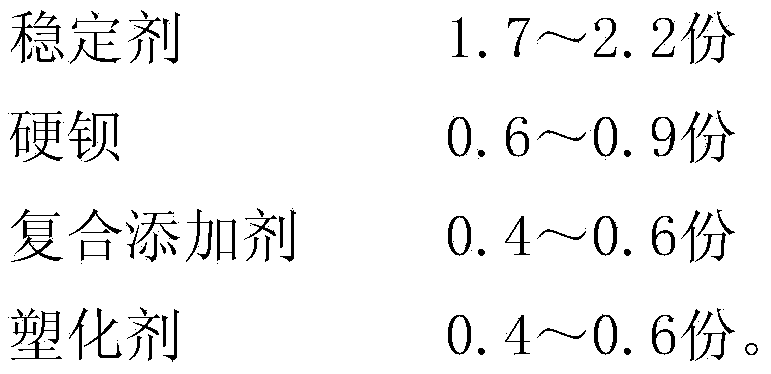

[0021] A 70°C PVC cable sheath formulation, the formulation includes resin, calcium powder, p-benzene, o-benzene, liquid wax, stabilizer, hard barium, compound additives and plasticizer. The weight parts of each component are as follows:

[0022]

[0023] The composite additive is a mixture of fatty acid and hard wax, and the mass ratio of the fatty acid and hard wax is 3:2.

Embodiment 2

[0025] A 70°C PVC cable sheath formulation, the formulation includes resin, calcium powder, p-benzene, o-benzene, liquid wax, stabilizer, hard barium, compound additives and plasticizer. The weight parts of each component are as follows:

[0026]

[0027] The composite additive is a mixture of fatty acid and hard wax, and the mass ratio of the fatty acid and hard wax is 3:2.

Embodiment 3

[0029] A 70°C PVC cable sheath formulation, the formulation includes resin, calcium powder, p-benzene, o-benzene, liquid wax, stabilizer, hard barium, compound additives and plasticizer. The weight parts of each component are as follows:

[0030]

[0031] The composite additive is a mixture of fatty acid and hard wax, and the mass ratio of the fatty acid and hard wax is 3:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com