Formula for improving effective prestress of concrete tubular pile

A concrete pipe pile and prestressing technology, which is applied in the field of pipe pile manufacturing, can solve problems such as the inability of the effective prestress value to be satisfied, and achieve the effects of improving the effective prestressing, reasonable material collocation and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

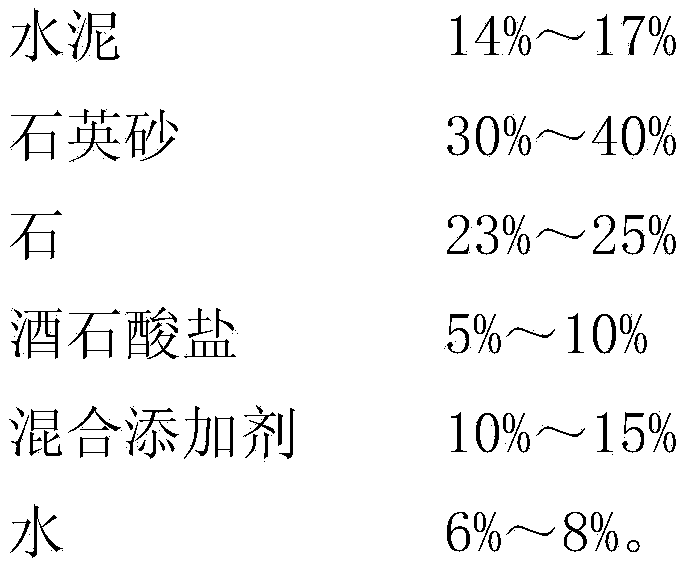

[0015] A formula for improving the effective prestress of concrete pipe piles, the formula includes cement, quartz sand, stone, tartrate, mixed additives and water, and the mass percentage of each component is as follows:

[0016]

[0017] The mixed additive includes sodium chlorate, sodium carbonate and quicklime, and the sodium chlorate, sodium carbonate and quicklime are mixed according to the ratio of 2:2:1.5.

[0018] The effect of using this ratio is as follows:

[0019] Pipe pile outer diameter Wall thickness Effective prestress

[0020] 400mm 95mm 8.1N / mm 2

[0021] The effect of using common pipe pile material ratio is as follows:

[0022] Pipe pile outer diameter Wall thickness Effective prestress

[0023] 400mm 95mm 4.0N / mm 2

[0024] From the comparison of the above two sets of data, it can be seen that under the same outer diameter and wall thickness, the effect of the pipe pile after adopting this ratio has a significant improvement in the effective pres...

Embodiment 2

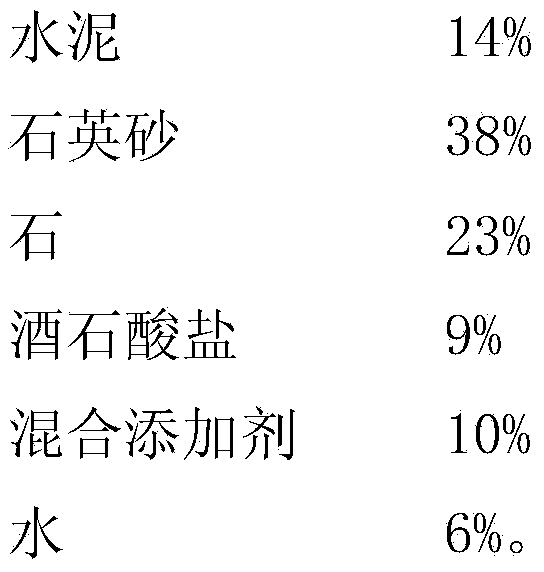

[0026] A formula for improving the effective prestress of concrete pipe piles, the formula includes cement, quartz sand, stone, tartrate, mixed additives and water, and the mass percentage of each component is as follows:

[0027]

[0028] The mixed additive includes sodium chlorate, sodium carbonate and quicklime, and the sodium chlorate, sodium carbonate and quicklime are mixed according to the ratio of 2:2:1.5.

[0029] The effect of using this ratio is as follows:

[0030] Pipe pile outer diameter Wall thickness Effective prestress

[0031] 500mm 100mm 8.25N / mm 2

[0032] The effect of using common pipe pile material ratio is as follows:

[0033] Pipe pile outer diameter Wall thickness Effective prestress

[0034] 500mm 100mm 6.0N / mm 2

[0035] From the comparison of the above two sets of data, it can be seen that under the same outer diameter and wall thickness, the effect of the pipe pile after adopting this ratio has a significant improvement in the effective p...

Embodiment 3

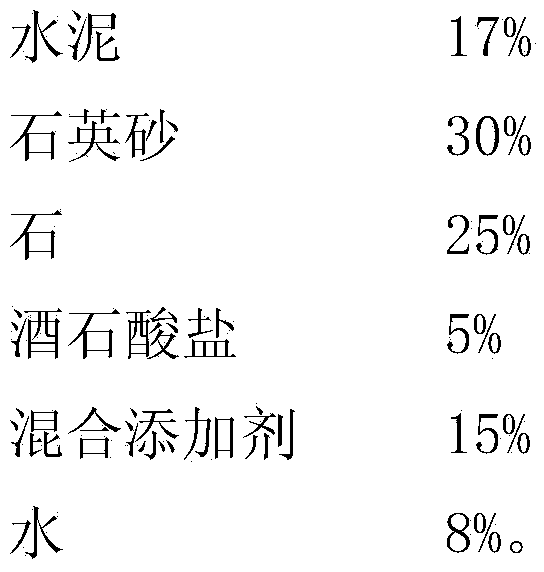

[0037] A formula for improving the effective prestress of concrete pipe piles, the formula includes cement, quartz sand, stone, tartrate, mixed additives and water, and the mass percentage of each component is as follows:

[0038]

[0039] The mixed additive includes sodium chlorate, sodium carbonate and quicklime, and the sodium chlorate, sodium carbonate and quicklime are mixed according to the ratio of 2:2:1.5.

[0040] The effect of using this ratio is as follows:

[0041] Pipe pile outer diameter Wall thickness Effective prestress

[0042] 600mm 110mm 8.5N / mm 2

[0043] The effect of using common pipe pile material ratio is as follows:

[0044] Pipe pile outer diameter Wall thickness Effective prestress

[0045] 600mm 110mm 8.0N / mm 2

[0046] From the comparison of the above two sets of data, it can be seen that under the same outer diameter and wall thickness, the effect of the pipe pile after adopting this ratio has a significant improvement in the effective pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com