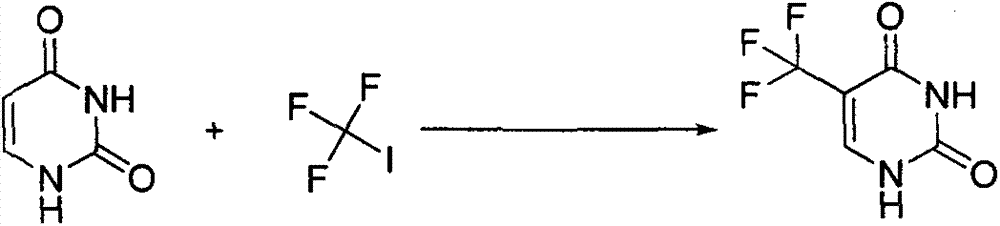

Synthesis method of 5-(trifluoromethyl) uracil

A technology of trifluoromethyluracil and uracil, which is applied in the field of preparation of 5-trimethyluracil, can solve the problems of high price, inconvenient purification, unsuitable for industrial operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

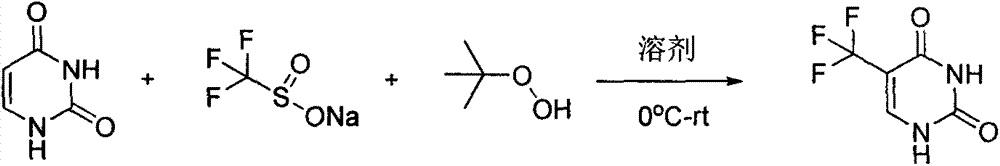

Method used

Image

Examples

Embodiment 1

[0011] 1) Add 100 g (0.89 mol) of raw material uracil, 460.7 g (2.95 mol) of sodium trifluoromethanesulfinate and 5.0 L of water into the reaction flask, and cool in an ice bath.

[0012] 2) Slowly add 474 g (5.27 moles) of tert-butyl hydroperoxide dropwise, keeping the system temperature below 10°C. After the dropwise addition, the temperature was naturally raised to room temperature, 20 g of copper sulfate was added, and stirring was continued at 250 rpm.

[0013] 3) LCMS detects that the raw material reacts almost completely after 5 days

[0014] 4) Add saturated aqueous sodium thiosulfate solution to quench the peroxide, stir for 1 hour and then filter.

[0015] 5) The filtrate was extracted three times with 5.5 L of ethyl acetate, the organic phases were combined, washed with water (3 L) and saturated brine (3 L), dried over anhydrous sodium sulfate, filtered, and spin-dried to obtain a white solid.

[0016] 6) The white solid obtained in 5 was beaten with 550 mL (EtOAc...

Embodiment 2

[0018] 1) Add 100 g (0.89 mol) of raw material uracil, 460.7 g (2.95 mol) of sodium trifluoromethanesulfinate and 5.0 L of water into the reaction flask, and cool in an ice bath.

[0019] 2) Slowly add 474 g (5.27 moles) of tert-butyl hydroperoxide dropwise, keeping the system temperature below 10°C. After the dropwise addition, the temperature was naturally raised to room temperature, 20 g of copper sulfate was added, and stirring was continued at 500 rpm.

[0020] 3) LCMS detects that the raw material reacts almost completely after 5 days

[0021] 4) Add saturated aqueous sodium thiosulfate solution to quench the peroxide, stir for 1 hour and then filter.

[0022] 5) The filtrate was extracted three times with 5.5 L of ethyl acetate, the organic phases were combined, washed with water (3 L) and saturated brine (3 L), dried over anhydrous sodium sulfate, filtered, and spin-dried to obtain a white solid.

[0023] 6) The white solid obtained in 5 was beaten with 550 mL (EtOAc...

Embodiment 3

[0025] 1) Add 100 g (0.89 mol) of raw material uracil, 460.7 g (2.95 mol) of sodium trifluoromethanesulfinate and 5.0 L of water into the reaction flask, and cool in an ice bath.

[0026] 2) Slowly add 474 g (5.27 moles) of tert-butyl hydroperoxide dropwise, keeping the system temperature below 10°C. After the dropwise addition, the temperature was naturally raised to room temperature, and continued to stir at 250 per minute for 5 days.

[0027] 3) Add saturated aqueous sodium thiosulfate solution to quench the peroxide, stir for 1 hour and then filter.

[0028] 4) The filtrate was extracted three times with 5.5 L of ethyl acetate, the organic phases were combined, washed with water (3 L) and saturated brine (3 L), dried over anhydrous sodium sulfate, filtered, and spin-dried to obtain a white solid.

[0029] 5) The white solid obtained in 4 was beaten with 550 mL (EtOAc:PE=1:10) for 2 hours, filtered, the filter cake was washed with PE, and dried to obtain 75 g of the produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com