Diatomite ceramic and preparation method thereof

A technology of diatomite and ceramics, applied in the field of ceramics, can solve the problems that the advantages are not widely promoted, and achieve the effects of hard and durable quality, strong adsorption capacity, and white and clean glaze.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of diatomite ceramic, is made up of the component of following weight ratio:

[0036] Diatomaceous earth 46%;

[0037] Kaolin 35%;

[0038] Aluminum oxide 2%;

[0039] Boron glass 1%;

[0041] Feldspar 9%;

[0042] Phosphogypsum 2%;

[0043] Leaf paraffin 1%;

[0044] Silica powder 2%;

[0045] Citrate 1%.

[0046] Above-mentioned diatomite ceramics are made by following method:

[0047] 1. Add water to diatomite, kaolin, alumina, boron glass, chromium oxide, feldspar, phosphogypsum, phylloparaffin, microsilica powder and citrate in the above weight ratio to make a slurry and then make a green body;

[0048] 2. Biscuit the prepared green body, and the bisque firing temperature is 760-830°C;

[0049] 3. Glaze after bisque firing;

[0050] 4. After glazing, fire at 1260-1300°C and keep at 1260-1300°C for 2 hours to make a finished product.

Embodiment 2

[0052] A kind of diatomite ceramic, is made up of the component of following weight ratio:

[0053] Diatomaceous earth 45%;

[0054] Kaolin 33%;

[0055] Aluminum oxide 2%;

[0056] Boron glass 2%;

[0057] Chromium oxide 2%;

[0058] Feldspar 8%;

[0059] Phosphogypsum 3%;

[0060] Leaf paraffin 1%;

[0061] Silica powder 1%;

[0062] Citrate 1%.

[0063] Above-mentioned diatomite ceramics are made by following method:

[0064] 1. Add water to diatomite, kaolin, alumina, boron glass, chromium oxide, feldspar, phosphogypsum, phylloparaffin, microsilica powder and citrate in the above weight ratio to make a slurry and then make a green body;

[0065] 2. Biscuit the prepared green body, and the bisque firing temperature is 760-830°C;

[0066] 3. Glaze after bisque firing;

[0067] 4. After glazing, fire at 1260-1300°C and keep at 1260-1300°C for 2 hours to make a finished product.

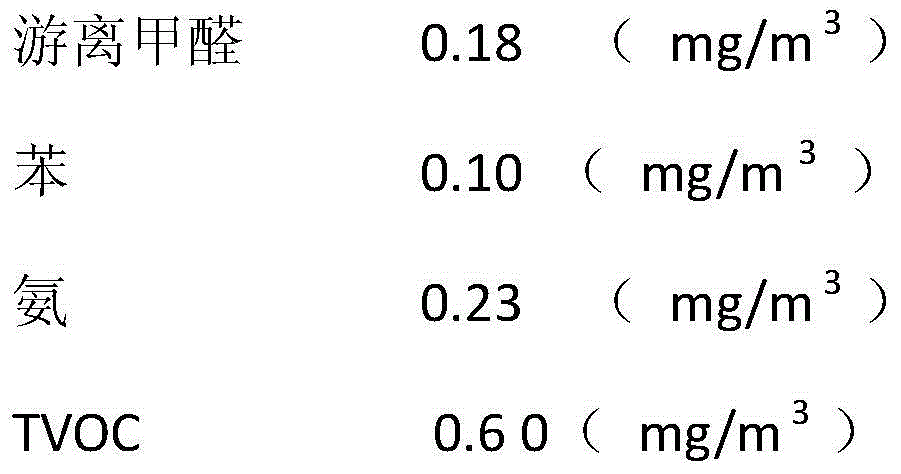

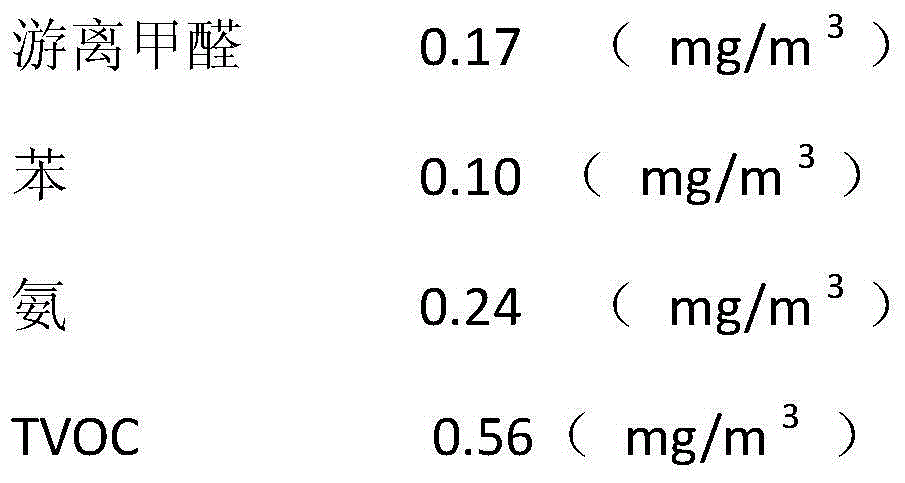

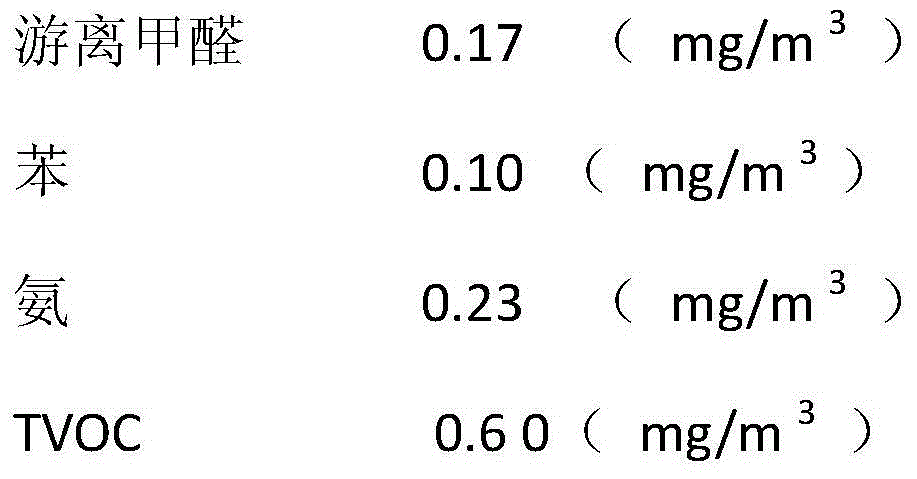

[0068] Use two bedrooms A and B which have the same area and have been decorated at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com