Tube fin radiator automatic pipe threading mechanism

A heat sink, automatic piercing technology, applied in hand-held tools, metal processing, metal processing equipment, etc., can solve the problems of difficult perforation operation, high labor intensity, inaccurate positioning, etc., and achieve simple perforation operation, low labor intensity, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

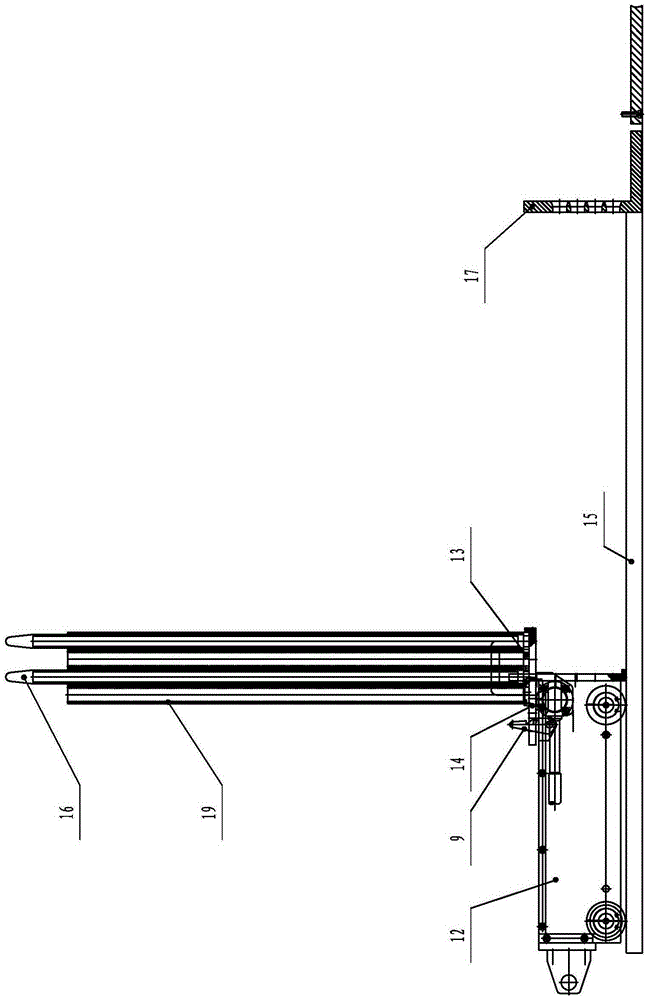

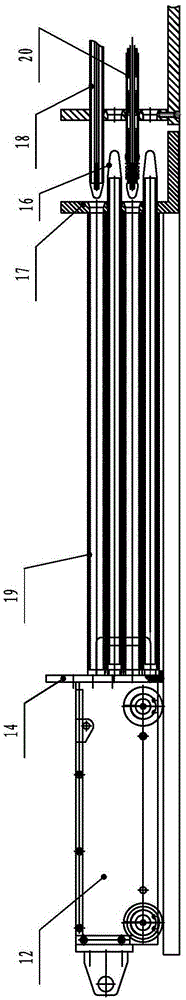

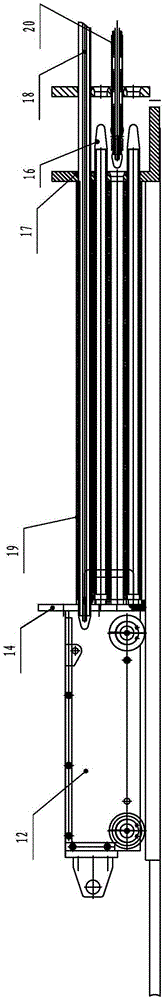

[0020] Specific implementation: The automatic tube threading mechanism of the tube-fin radiator in this embodiment includes a chip threading vehicle 12, a turning table 14, a chip collection frame 13, an assembly table 15, two single-feeding rods 18 and a plurality of pull tube positioning rods 20 ;

[0021] The film loading vehicle 12 is arranged on the assembly platform 15, the overturning platform 14 is rotatably connected to the upper right end of the film loading vehicle 12, the chip collection frame 13 is installed on the overturning platform 14, and the fins 19 are passed through the chip collection rods of the chip collection frame 13 16, when the fins are transferred, the fin collection frame 13 is perpendicular to the assembly platform 15; when passing through the tube, the fin collection frame 13 puts the fins 19 flat on the assembly platform 15 through the turning platform 14, and the heat sink end plate 17 is placed on the assembly platform On the right side, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com