A fast-change high-precision positioning and locking device and method for one-out multi-mould compression mold

A positioning locking and high-precision technology, which is applied in the field of quick-change high-precision positioning and locking devices for multi-mould pressing molds, can solve the problems of long mold changing time, low mold loading accuracy, and high labor intensity, and achieves low cost and high structure. Simple, high positioning accuracy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

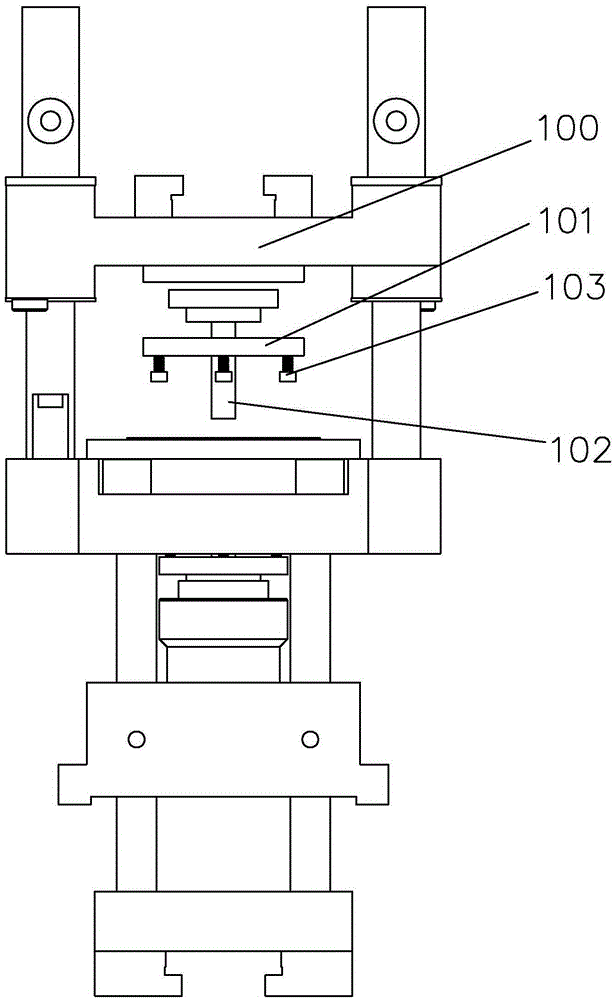

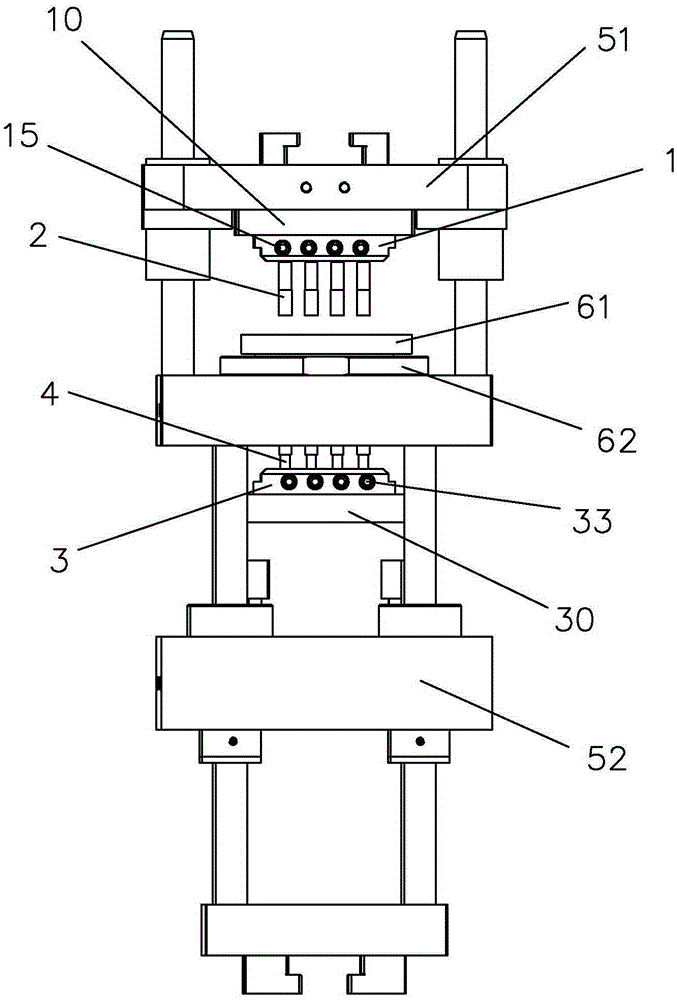

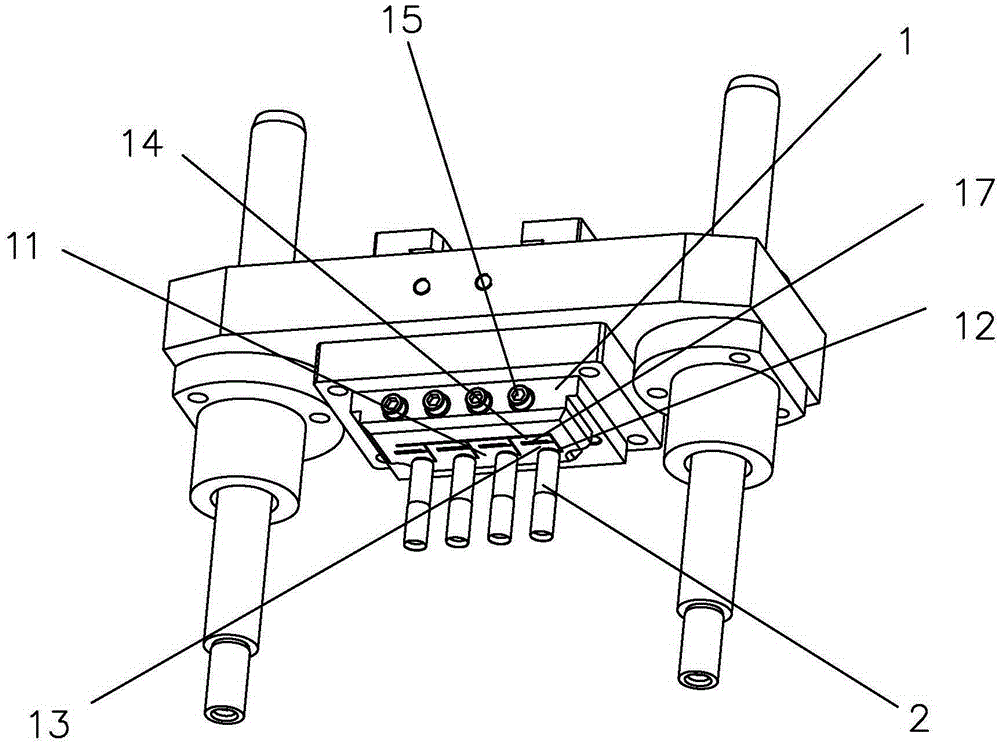

[0043] see Figure 2 to Figure 5 As shown, a quick-change high-precision positioning and locking device for one-out multi-molding molds of the present invention includes:

[0044] An upper template base 10 that can be used to be connected to the upper template 51 of the formwork and an integral upper punch clamp body 1 that can be used to connect the upper punch, the upper punch clamp body 1 is fixedly connected to the upper template base 10 On the lower side, the upper punch clamp body 1 is provided with a plurality of first connecting parts for separately installing the upper punch 2, and each first connecting part is respectively provided with a first positioning part and a first positioning part for positioning the corresponding upper punch 2. Used to fix the first locking part of the corresponding upper punch, the first locking part is arranged on the side of the corresponding first positioning part, and locks the upper punch 2 put into the corresponding first positioning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com