Composite separating membrane and preparation method and application thereof

A separation membrane and separation layer technology, applied in separation methods, semi-permeable membrane separation, dispersed particle separation, etc., can solve the problems of affecting the service life of the membrane, insufficient physical and chemical stability, and degradation of membrane performance, so as to achieve easy control, Effect of improving resistance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

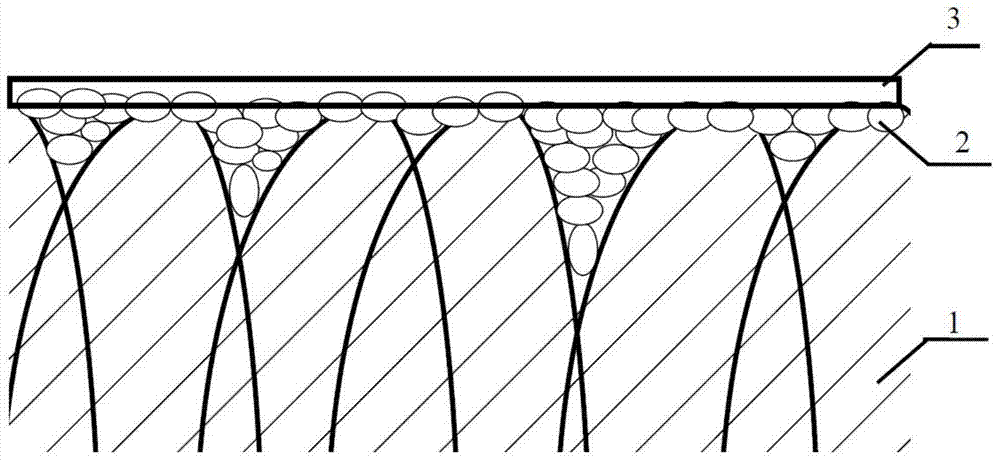

[0070] This embodiment discloses a composite separation membrane and its manufacturing method, such as figure 1 As shown, it includes a bottom film 1, a transition layer 2 composed of MOF particles, and a separation layer 3. The composite membrane of this embodiment is prepared by the following steps:

[0071] (1) Clean the surface of the polyacrylonitrile base film and dry it;

[0072] (2) Add ZIF-7 to pure water 5 times and ultrasonicate for 60 minutes at the same time to prepare a suspension with a concentration of 1wt.% for later use.

[0073] (3) Coat the ZIF-7 suspension of step (2) on the base film of step (1), dry in the shade at room temperature for 60 minutes, and then take it out after further drying at 80°C for 2 hours;

[0074] (4) After soaking the membrane in step (3) in 2wt.% PEBA solution for 1min, take the membrane out of the solution and dry it in the shade at room temperature for 20min;

[0075] (5) Put the film obtained in step (4) into a blast oven for...

Embodiment 2

[0078] This embodiment discloses a composite separation membrane and its manufacturing method. The composite separation membrane in this embodiment is prepared by the following steps:

[0079] (1) Clean the surface of the polyacrylonitrile base film and dry it;

[0080] (2) Add ZIF-7 to pure water 5 times and ultrasonicate for 60 minutes at the same time to prepare a suspension with a concentration of 1.5wt.% for later use.

[0081] (3) Coat the ZIF-7 suspension of step (2) on the base film of step (1), dry in the shade at room temperature for 60 minutes, and then take it out after further drying at 80°C for 2 hours;

[0082] (4) After soaking the membrane in step (3) in 2wt.% PEBA solution for 1min, take the membrane out of the solution and dry it in the shade at room temperature for 20min;

[0083] (5) Put the film obtained in step (4) into a blast oven for further drying under heating conditions, the drying temperature is 80°C, take it out after heating in the oven for 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com