Preparation method of pickled bamboo shoots with pickled peppers

A technology of bamboo shoots and pickled peppers, applied in food preparation, application, food science and other directions, can solve the problems of inconsistent product taste and poor product taste, and achieve the effects of crisp texture, improved taste and good taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

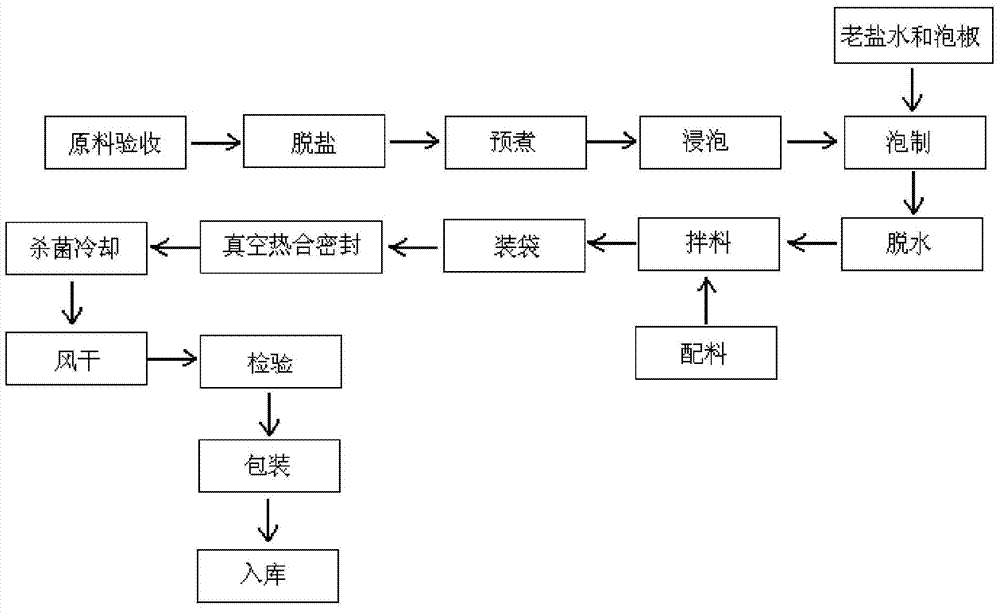

Method used

Image

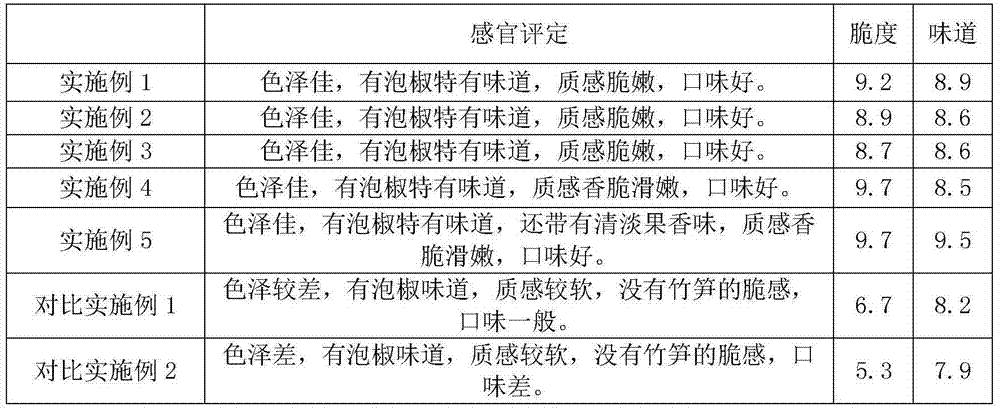

Examples

Embodiment 1

[0036] Embodiment 1 pickled pepper bamboo shoots

[0037] Follow the example steps below:

[0038] (1) Raw material pretreatment

[0039] soaking the above precooked bamboo shoots in ice-water mixture at 0°C for 2 hours;

[0040] (2) brewing

[0041] Take the soaked Sansho pepper, balance its salinity to 10 degrees, acidity to 6‰, and pre-cook it at 100°C for 15 minutes to get the pre-cooked Sansho pepper;

[0042] Take the old brine, balance its salinity to 10 degrees, and its acidity to 6‰, and reserve it;

[0043] Put the precooked sansho and the bamboo shoots soaked in step (1) into the prepared old salt water, soak for 20 hours at 25±2°C, and by weight, the ratio of the bamboo shoots, old salt water and sansho It is 100:100:12.

[0044] (3) Ingredients and ingredients

[0045] Take an appropriate amount of common food seasonings to prepare ingredients, after dehydrating the bamboo shoots soaked in step (2), take an appropriate amount of ingredients and stir and mix ...

Embodiment 2

[0046] Embodiment 2 pickled pepper bamboo shoots

[0047] Follow the example steps below:

[0048] (1) Raw material pretreatment

[0049] Soaking the above precooked bamboo shoots at -2°C for 2 hours;

[0050] (2) brewing

[0051] Take the soaked Sansho pepper, balance its salinity to 10 degrees, acidity to 6‰, and pre-cook it at 100°C for 15 minutes to get the pre-cooked Sansho pepper;

[0052] Take the old brine, balance its salinity to 10 degrees, and acidity to 6‰, and set aside;

[0053] Put the precooked sansho and the bamboo shoots soaked in step (1) into the prepared old salt water, soak for 20 hours at 25±2°C, and by weight, the ratio of the bamboo shoots, old salt water and sansho It is 100:100:12.

[0054] (3) Ingredients and ingredients

[0055] Take an appropriate amount of common food seasonings to prepare ingredients, after dehydrating the bamboo shoots soaked in step (2), take an appropriate amount of ingredients and stir and mix with the dehydrated bambo...

Embodiment 3

[0056] Embodiment 3 pickled pepper bamboo shoots

[0057] Follow the example steps below:

[0058] (1) Raw material pretreatment

[0059] Soaking the precooked bamboo shoots at -5°C for 2 hours;

[0060] (2) brewing

[0061] Take the soaked Sansho pepper, balance its salinity to 10 degrees, acidity to 6‰, and pre-cook it at 100°C for 15 minutes to get the pre-cooked Sansho pepper;

[0062] Take the old brine, balance its salinity to 10 degrees, and its acidity to 6‰, and reserve it;

[0063] Put the precooked sansho and the bamboo shoots soaked in step (1) into the prepared old salt water, soak for 20 hours at 25±2°C, and by weight, the ratio of the bamboo shoots, old salt water and sansho It is 100:100:12.

[0064] (3) Ingredients and ingredients

[0065] Take an appropriate amount of common food seasonings to prepare ingredients, after dehydrating the bamboo shoots soaked in step (2), take an appropriate amount of ingredients and stir and mix with the dehydrated bamboo s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com