A kind of silkworm rearing grid

A technology of silkworm and trellis, which is applied in the field of silkworm breeding equipment, can solve the problems of labor-consuming and time-consuming silkworm breeding, single function of silkworm craftsmen, and difficulty in thorough disinfection, and achieves time-saving and labor-saving use, simple manufacturing process, and easy promotion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

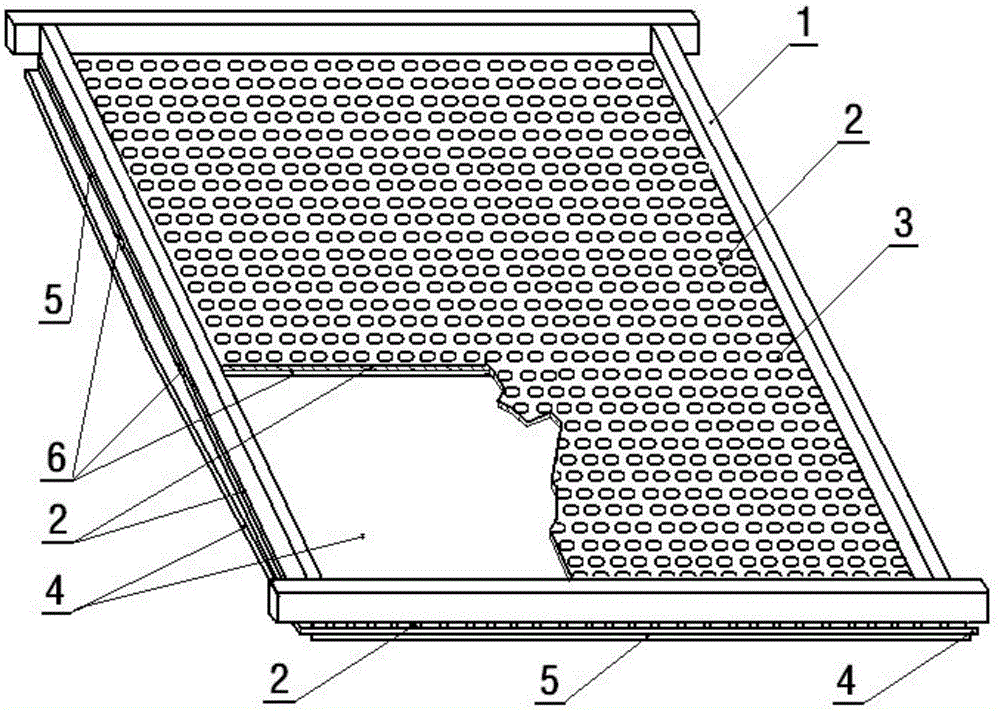

[0023] As shown in Figure 1, this silkworm rearing grid is provided with grid frame 1, net sheet 2, bearing sand sheet 4, fixed bar 5, grid frame 1, mesh sheet 2, bearing sand sheet 4, fixed bar 5. The grid frame 1 has a rectangular structure and is made of square aluminum material. The front and rear ends of the grid frame 1 are provided with handles for mounting. The mesh 2 is plastic with circular mesh holes 3 . The sand bearing sheet 4 is a plastic sheet, and the sand bearing sheet 4 is longer and wider than the mesh sheet 2 . The fixing strip 5 is an aluminum metal strip, and the fixing strip 5 is provided with screw holes corresponding to the bottom of the grid frame 1 . The grid frame 1, the mesh sheet 2, the sand-bearing sheet 4, the fixing strip 5, the grid frame 1, the mesh sheet 2, the sand-bearing sheet 4, and the fixing strip 5 are arranged in order, and are fixed around the grid frame 1 by screws, wherein The long both sides of sand-bearing sheet 4 need not fix...

Embodiment 2

[0025] As shown in Figure 1, this silkworm rearing grid is provided with grid frame 1, net sheet 2, bearing sand sheet 4, fixed bar 5, grid frame 1, mesh sheet 2, bearing sand sheet 4, fixed bar 5. The grid frame 1 has a square structure and is made of square wooden strips. The front and rear ends of the grid frame 1 are provided with handles for mounting. The mesh 2 is an aluminum sheet provided with triangular mesh holes 3 . The sand bearing sheet 4 is a plastic sheet, and the sand bearing sheet 4 is longer and wider than the mesh sheet 2 . The fixing bar 5 is a thin iron bar, and the fixing bar 5 is provided with screw holes corresponding to the bottom of the lattice frame 1 . The grid frame 1, the mesh sheet 2, the sand-bearing sheet 4, the fixing strip 5, the grid frame 1, the mesh sheet 2, the sand-bearing sheet 4, and the fixing strip 5 are arranged in order, and are fixed around the grid frame 1 by screws, wherein The long both sides of sand-bearing sheet 4 need not ...

Embodiment 3

[0027] As shown in Figure 1, this silkworm rearing grid is provided with grid frame 1, net sheet 2, bearing sand sheet 4, fixed bar 5, grid frame 1, mesh sheet 2, bearing sand sheet 4, fixed bar 5. The grid frame 1 is a square structure, made of square wooden strips, and the front and rear ends of the grid frame 1 are provided with handles for mounting. The mesh 2 is a bamboo woven sheet provided with a zigzag mesh hole 3 . The sand bearing sheet 4 is a plastic sheet, and the sand bearing sheet 4 is longer and wider than the mesh sheet 2 . The fixing strip 5 is an aluminum sheet strip, and the fixing strip 5 is provided with screw holes corresponding to the bottom of the grid frame 1 . The grid frame 1, the mesh sheet 2, the sand-bearing sheet 4, the fixing strip 5, the grid frame 1, the mesh sheet 2, the sand-bearing sheet 4, and the fixing strip 5 are arranged in order, and are fixed around the grid frame 1 by screws, wherein The long both sides of sand-bearing sheet 4 do ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com