Direct current thermomagnetic release device and method for reducing temperature rise of terminal of the device

A thermal-magnetic release, current technology, applied in the direction of protection switch operation/release mechanism, etc., can solve the problems of terminal temperature rise, reduce the terminal temperature rise of DC thermal-magnetic release, and achieve the effect of reducing the terminal temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

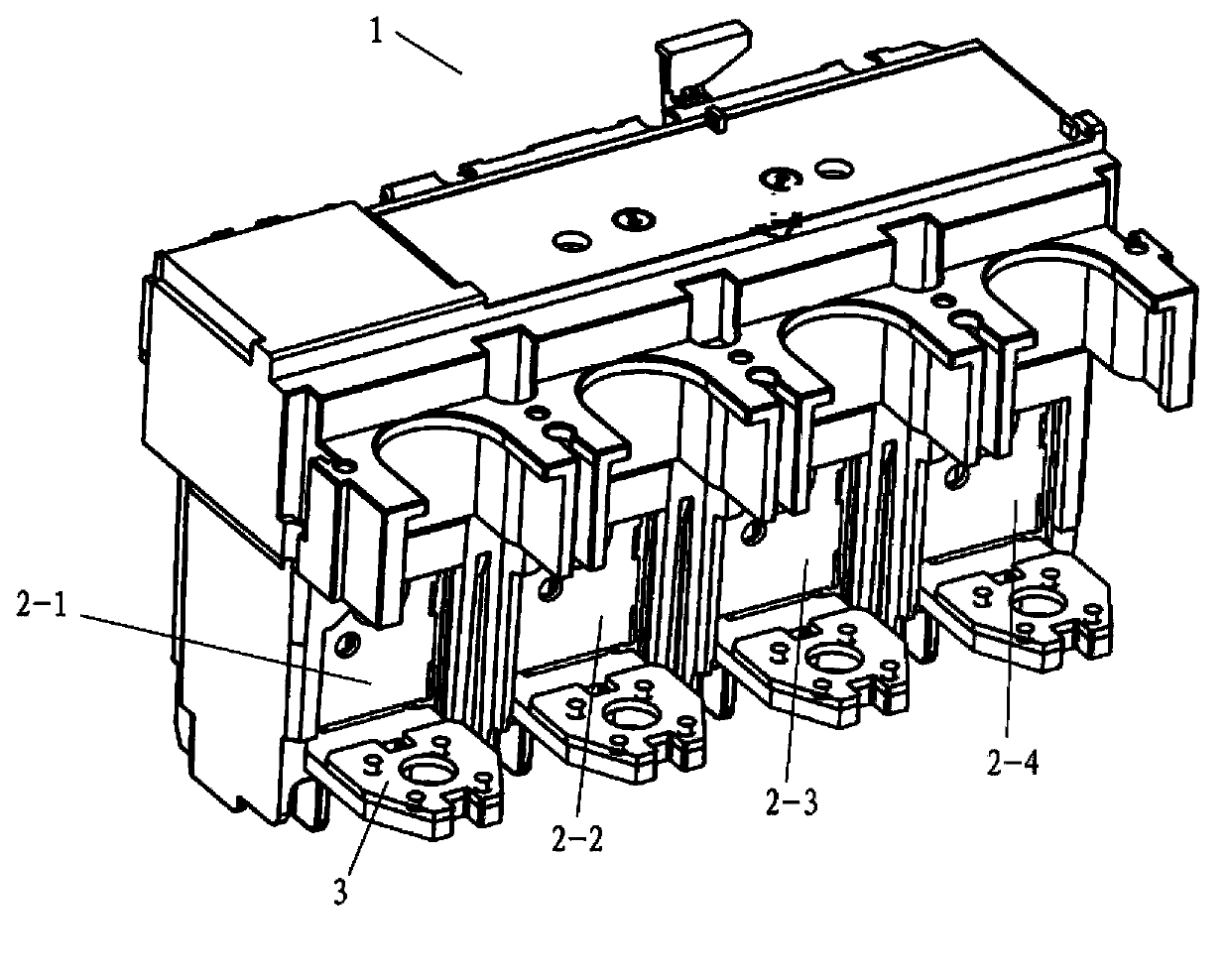

[0040] Refer below Figure 1 to Figure 4-4 The DC thermal-magnetic release device for reducing terminal temperature rise and the method for reducing the terminal temperature rise of the above-mentioned DC thermal-magnetic release are more clearly described.

[0041] figure 1It shows a perspective view of a first embodiment of a DC thermal-magnetic trip device for reducing terminal temperature rise according to the present invention. In this embodiment, the DC thermal-magnetic trip device 1 has a 4-pole heating element 2, One end of the heating element 2 is the terminal 3 . The heating element 2-1 and the heating element 2-3 have the same resistance, the heating element 2-2 and the heating element 2-4 have the same resistance, the two groups of resistances are different from each other, and are divided into high resistance heating elements 2-1, 2-3 and low-resistance heating elements 2-2, 2-4, the 4 heating elements, that is, 4-pole heating elements are connected in series wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com