Active energy ray curable resin composition and spacer for display device using the same and/or color filter protective layer

A technology of active energy rays and curable resins, applied in the direction of optical filters, optical elements, nonlinear optics, etc., can solve the problem that the elastic recovery rate is not satisfactory, and achieve excellent developability, excellent toughness, Effects of High Radiation Sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1~1-20

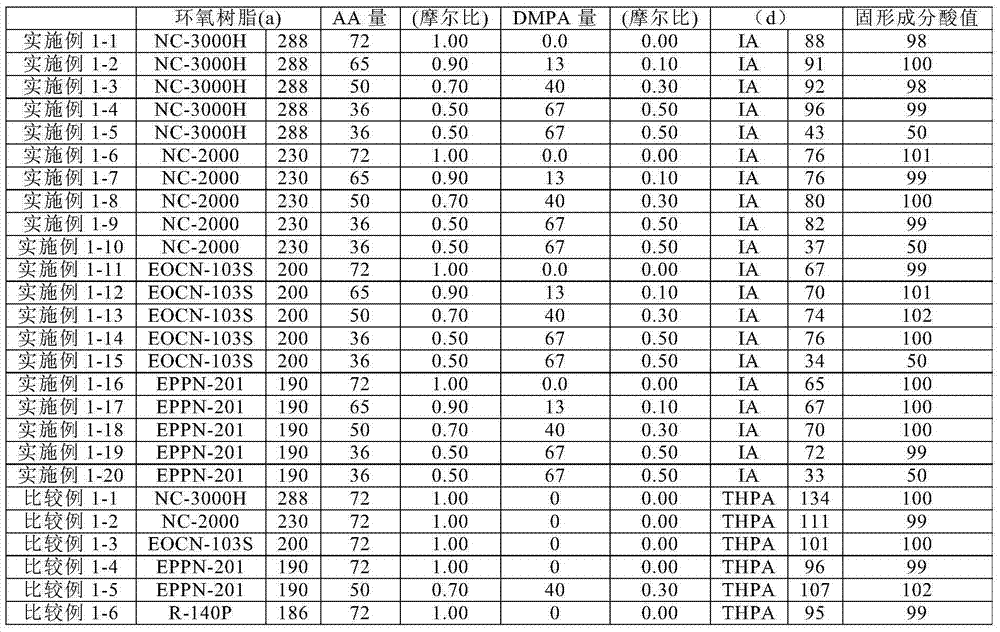

[0158] Examples 1-1 to 1-20: Preparation of reactive polycarboxylic acid compound (A)

[0159] NC-3000H (manufactured by Nippon Kayaku Co., Ltd., epoxy equivalent 288 g / eq) and NC-2000 (manufactured by Nippon Kayaku Co., Ltd., epoxy equivalent 230 g) were added as epoxy resin (a) in the amount described in Table 1 / eq), EOCN-103S (manufactured by Nippon Kayaku Co., Ltd., epoxy equivalent 200g / eq), EPPN-201 (manufactured by Nippon Kayaku Co., Ltd., epoxy equivalent 190g / eq), added in the amount described in Table 1 Acrylic acid (abbreviated as AA, Mw=72) as compound (b), and dimethylolpropionic acid (abbreviated as DMPA, Mw=134) as compound (c) were added in the amount described in Table 1. 3 g of triphenylphosphine was added as a catalyst, and propylene glycol monomethyl ether monoacetate was added as a solvent so that the solid content became 80% by mass of the reaction liquid. React at 100°C for 24 hours to obtain a reactive epoxy carboxylate compound (E) solution. The nex...

Synthetic example 1

[0182] 7 parts by mass of 2,2'-azobis(2,4-dimethylvaleronitrile) and 200 parts by mass of diethylene glycol methyl ethyl ether were charged into a flask equipped with a condenser tube and a stirrer. Next, 5 parts by mass of styrene, 16 parts by mass of methacrylic acid, 34 parts by mass of tetrahydrodicyclopentadienyl methacrylate, 40 parts by mass of glycidyl methacrylate, α-methylstyrene two 3 parts by mass of the polymer were replaced with nitrogen, and then 5 parts by mass of 1,3-butadiene was added, and stirring was started slowly. The temperature of the solution was raised to 70°C, and the temperature was maintained for 5 hours to obtain a polymer solution containing the copolymer [G-1]. The solid content concentration of the obtained polymer solution was 33.1%, and the weight average molecular weight of the polymer was 10,000.

[0183]

[0184] H-1: Fluorine-containing surfactant (Neos Co., Ltd., Futhergent FTX-218)

[0185] H-2: Silicone surfactant (Toray Dow Corni...

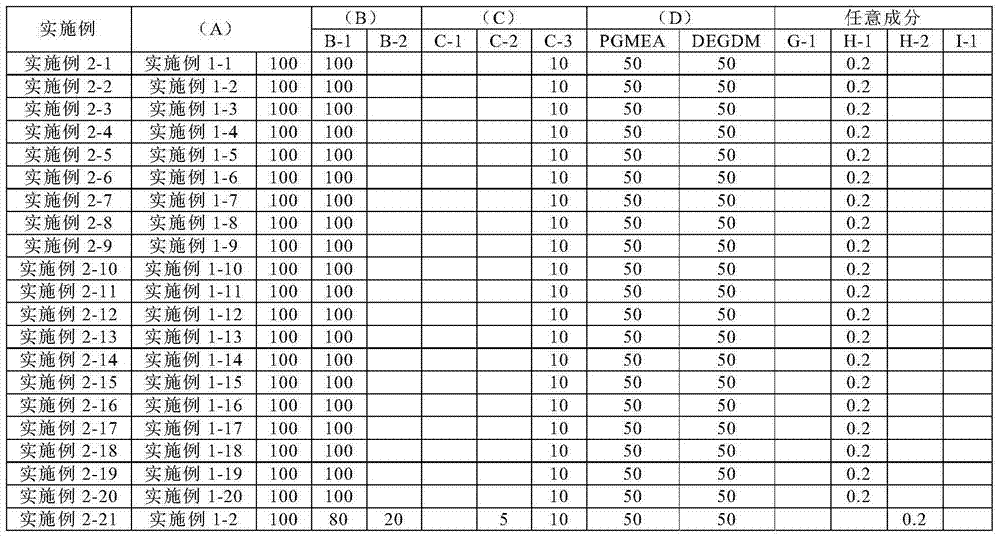

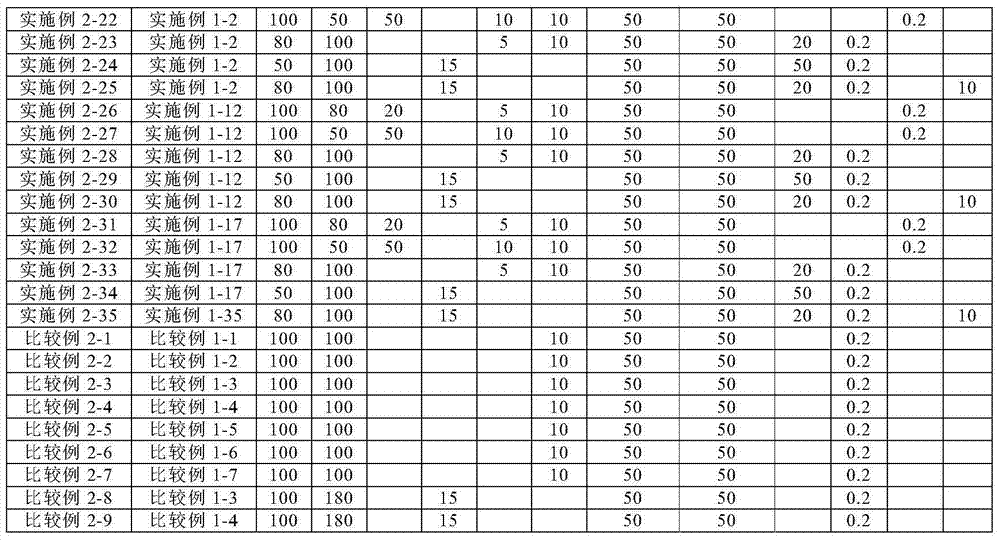

Embodiment 2-1

[0190] (B-1 ) 100 parts by mass, 10 parts by mass of (C-3) as a photopolymerization initiator (C), and adding PGMEA and DEGDM as an organic solvent to achieve the desired solid content concentration, mixed as a surfactant (H) ( H-1) 0.3 parts by mass were filtered through a membrane filter with a pore diameter of 0.2 μm to prepare the composition (S-1). In addition, the numerical value of the organic solvent in Table 2 is the mass ratio of PGMEA and DEGDM.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com