Non-contact method for measuring temperature of pumping medium

A medium temperature, non-contact technology, applied in the application of thermometers, thermometers, measuring devices, etc., can solve the problems that the rotor magnetic flux cannot be directly measured, the accuracy of calculation is affected, and the temperature coefficient of permanent magnet materials is inconsistent, so as to achieve accurate characterization. Winding Temperature, Accurate Characterization, Facilitate Effect of Winding Temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

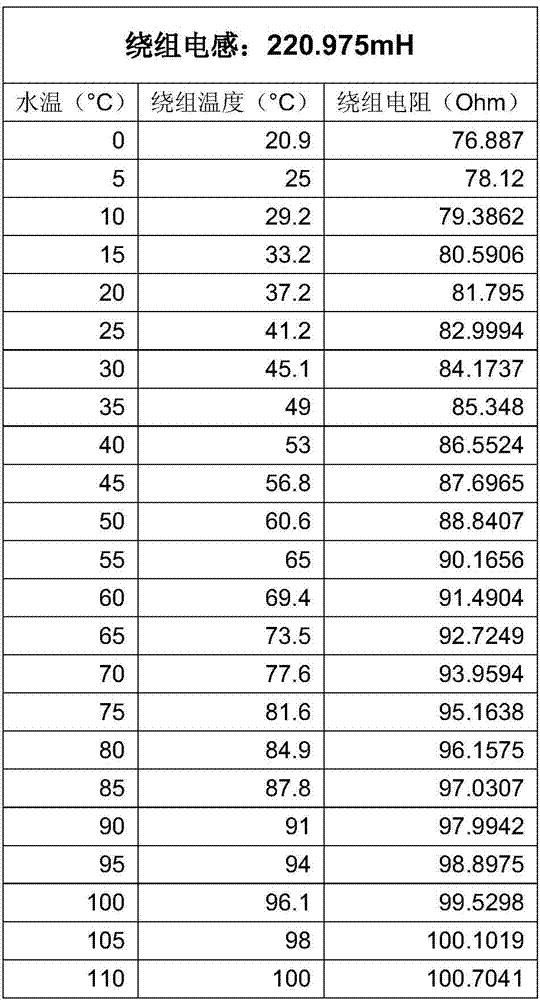

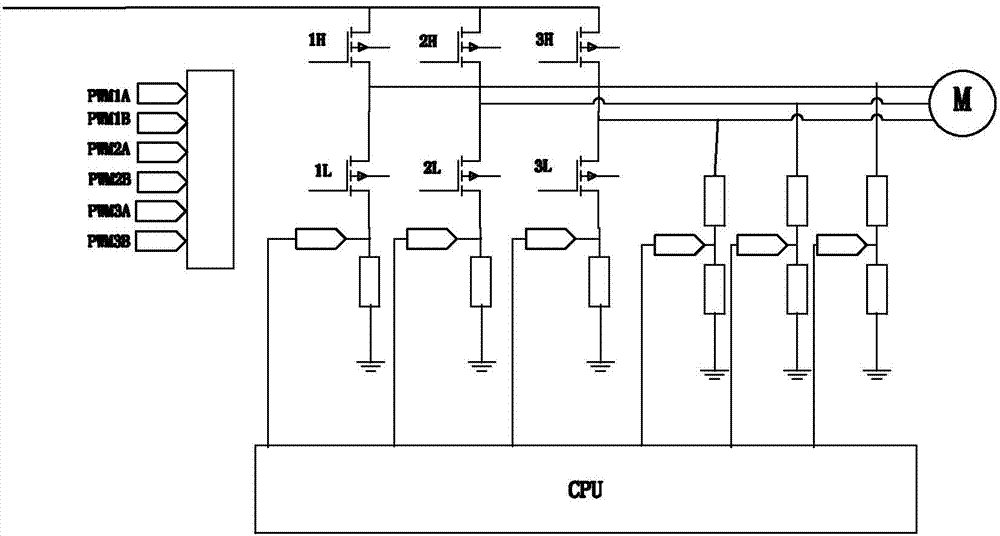

[0014] Embodiment 1: The method for non-contact measurement of the temperature of the pumped medium, which includes step one: the rotor in the motor on the pump body is immersed in the fluid and runs; step two: when the motor is running, in the non-conductive phase Inject high-frequency current, and detect the induced potential of the non-conducting phase, detect the current, frequency and stator inductance, step 3: combine the induced potential, current, frequency and stator inductance to obtain the stator coil resistance, and then obtain the stator coil Temperature; Step 5, according to the linear relationship between the temperature of the stator coil and the temperature of the medium, the temperature of the medium is obtained. The motor is a permanent magnet motor with a controller, and the rotor of the motor is provided with a permanent magnet providing magnetic flux. Using a full bridge circuit in a controller connected in series with the motor (eg figure 1 shown) to ge...

Embodiment 2

[0035] Embodiment 2: The method for non-contact measurement of the temperature of the pumped medium also includes step 6: using a temperature sensor, immersing the motor in water and running it, measuring the resistance of the stator coil and the temperature of the stator coil at different ambient temperatures, and establishing a table, And establish temperature, stator coil resistance and stator coil temperature curves according to the table (such as figure 1 and figure 2 shown); Step 7: According to the table and graph in Step 6, combined with the linear relationship between the temperature of the stator coil and the temperature of the medium, the temperature of the medium is obtained. All the other steps 1 to 5 are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com