Drying method of ceramic billet and energy-saving fast drying kiln used therein

A drying method and rapid drying technology, applied in the field of ceramic blank drying, energy-saving and rapid drying kiln, can solve the problems of high fuel consumption and power consumption, and achieve the effect of avoiding cracking and small temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

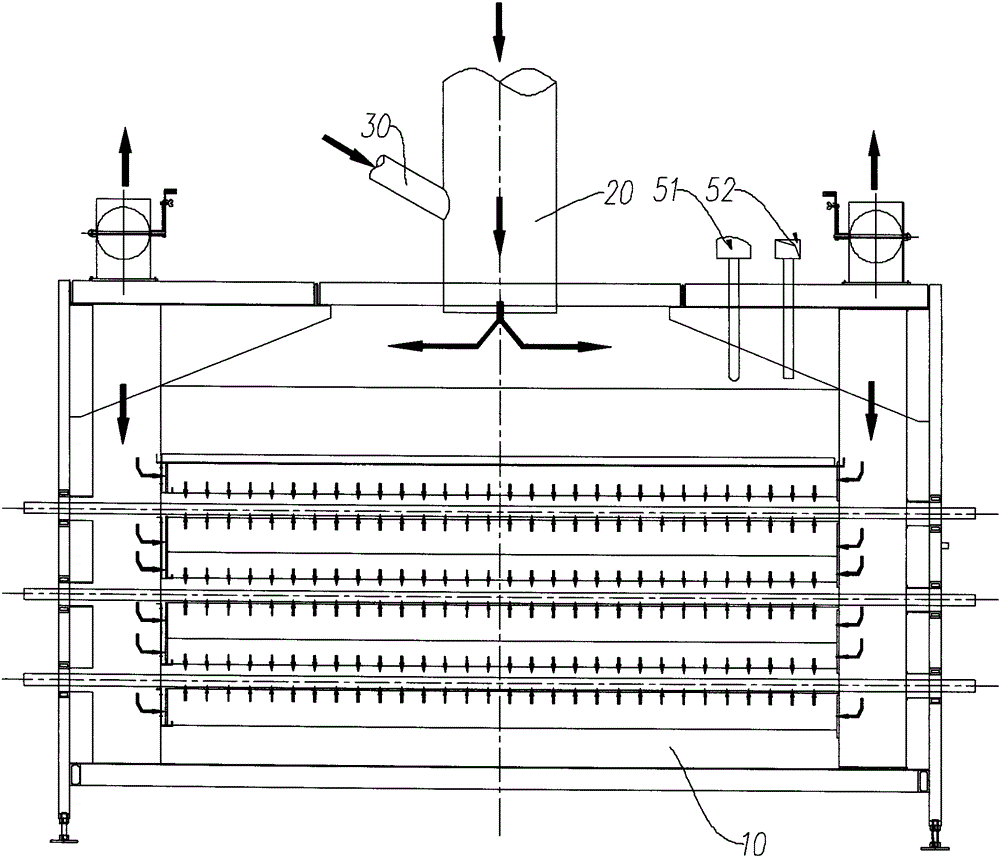

[0022] Embodiment: The drying method of the ceramic body of the present invention includes passing heat medium such as hot air into the drying kiln, so that the drying kiln has sufficient temperature. At the same time, water vapor is mixed in the heat medium. In this way, the heat medium can maintain an appropriate amount of humidity, and through appropriate adjustments, the balance of water loss in various parts of the green body can be effectively maintained, thereby avoiding greater stress inside the green body during the drying process, thereby avoiding the cracking of the brick . At the same time, the water vapor is mixed with the heat medium before it enters the drying kiln. In this way, compared with other methods of mixing normal temperature water and heat medium outside the drying kiln, the defect of absorbing a large amount of heat energy after the water is heated and vaporized is avoided, so that it is more energy-saving.

[0023] Optimally, the humidity of the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com