A high-temperature pure oxygen oil gun device for automatic stable combustion of power plant boilers

A technology for power station boilers and oil guns, which is applied to burners, burners, and combustion methods for burning powder fuels. It can solve the problems of poor low-nitrogen combustion performance, expensive transformation costs, and non-standard use, and achieves wide applicability and flexible operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

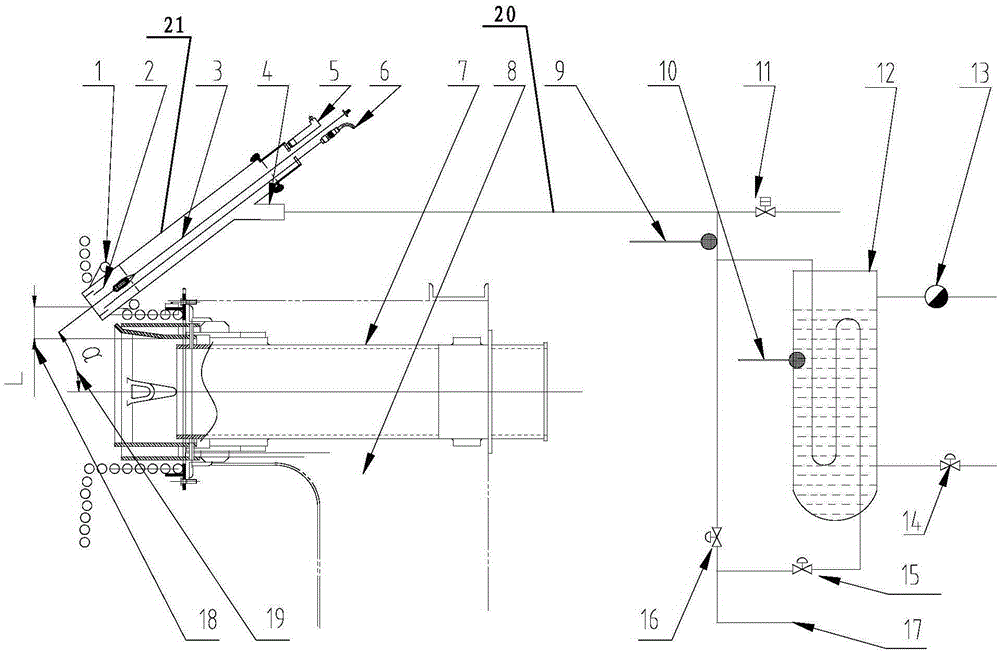

[0037] A high-temperature pure oxygen oil gun device for automatic stable combustion of power plant boilers, such as figure 1 As shown, it includes a water wall tube 1, a high temperature pure oxygen oil gun assembly, a pulverized coal burner 7, a hot air box 8, an oxygen heater 12, an oxygen main pipe 17 and an oxygen pipeline 20, and the pulverized coal burner 7 is installed in the On the hot air box 8, there is a hole between the water-cooled wall pipe 1 and the pulverized coal burner 7, and the high-temperature pure oxygen oil gun assembly is inserted into the hole through its bottom and connected to the water-cooled wall pipe 1 and the pulverized coal burner 7 are connected respectively, the high temperature pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com