Intermittent laser burning device and intermittent laser burning method

An intermittent, laser technology, used in laser welding equipment, marking meat/sausage, printing, etc., can solve the problems of inability to achieve engraving, insufficient engraving time, and difficult to identify engraving information, and achieve good engraving effect, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The description of the exemplary embodiments is for the purpose of illustration only, and in no way limits the invention and its application or usage.

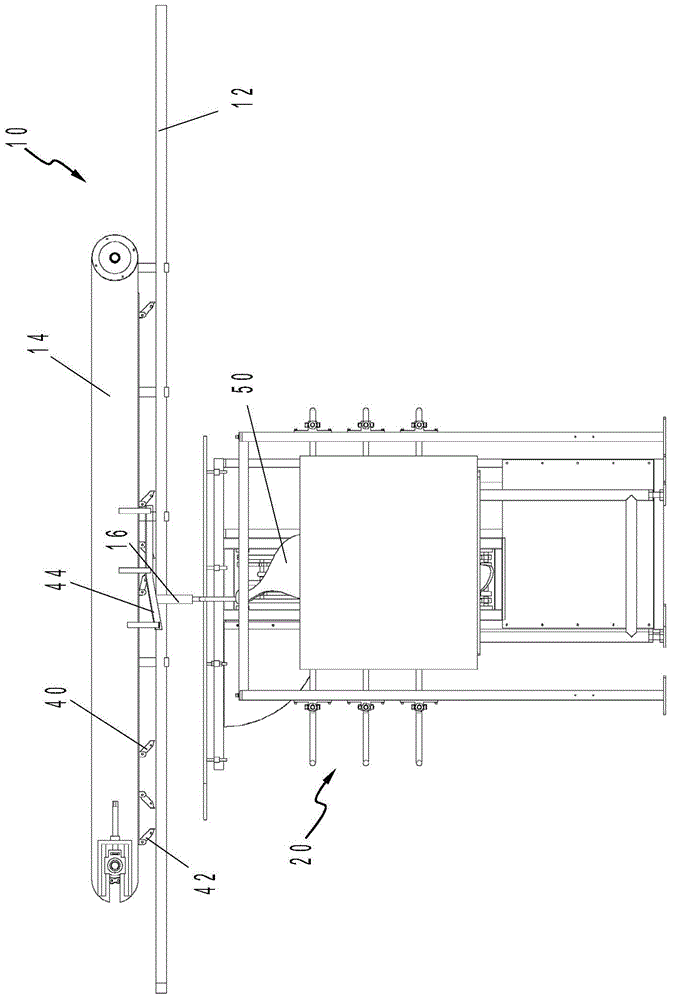

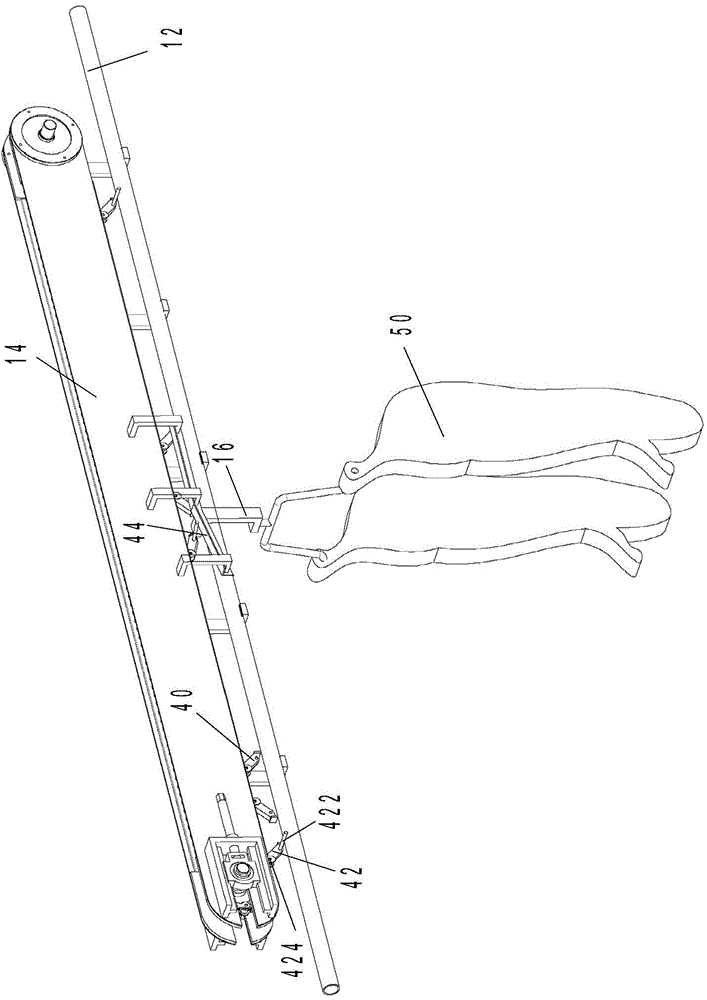

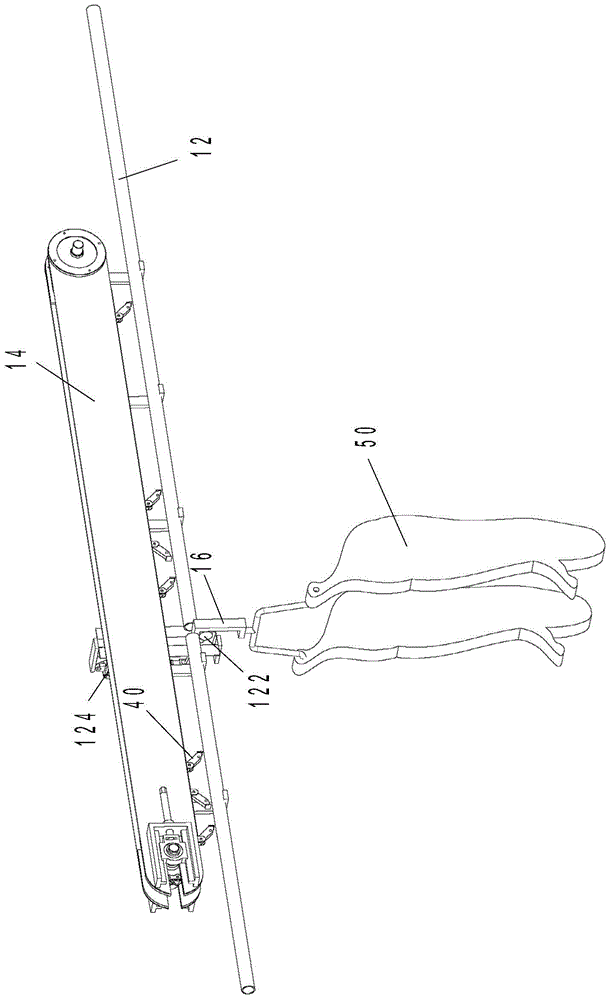

[0027] The invention provides an intermittent laser burning device which can realize intermittent burning of burning objects under the condition of continuous operation of the burning device. This intermittent laser burning device 10 comprises a conveying guide rail 12 fixedly arranged on the frame of the intermittent laser burning device 10, a conveying chain 14 arranged above the conveying guide rail approximately in parallel with the conveying guide rail, and a conveying chain 14 arranged on the conveyor guide rail slidably. The hook part 16 on the transport guide rail and the laser burning part 20 for burning the burning object 50 . like figure 1 As shown, the laser burning unit 20 may be a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com