Retarder cooling system

A technology of cooling system and retarder, which is applied in the direction of engine cooling, machine/engine, engine components, etc. It can solve the problems of low engine water temperature, unfavorable engine energy saving and emission reduction, and lower engine operating temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

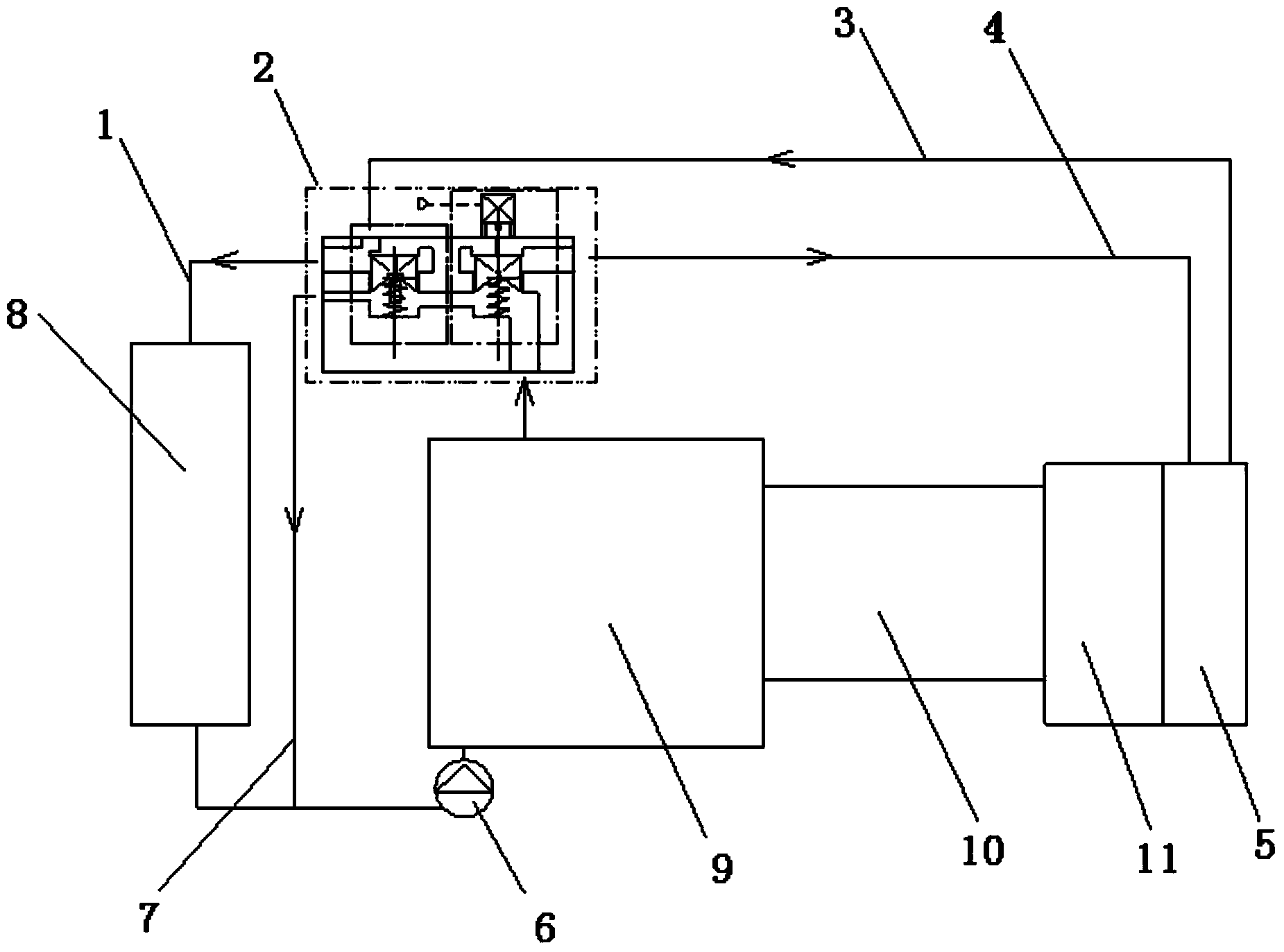

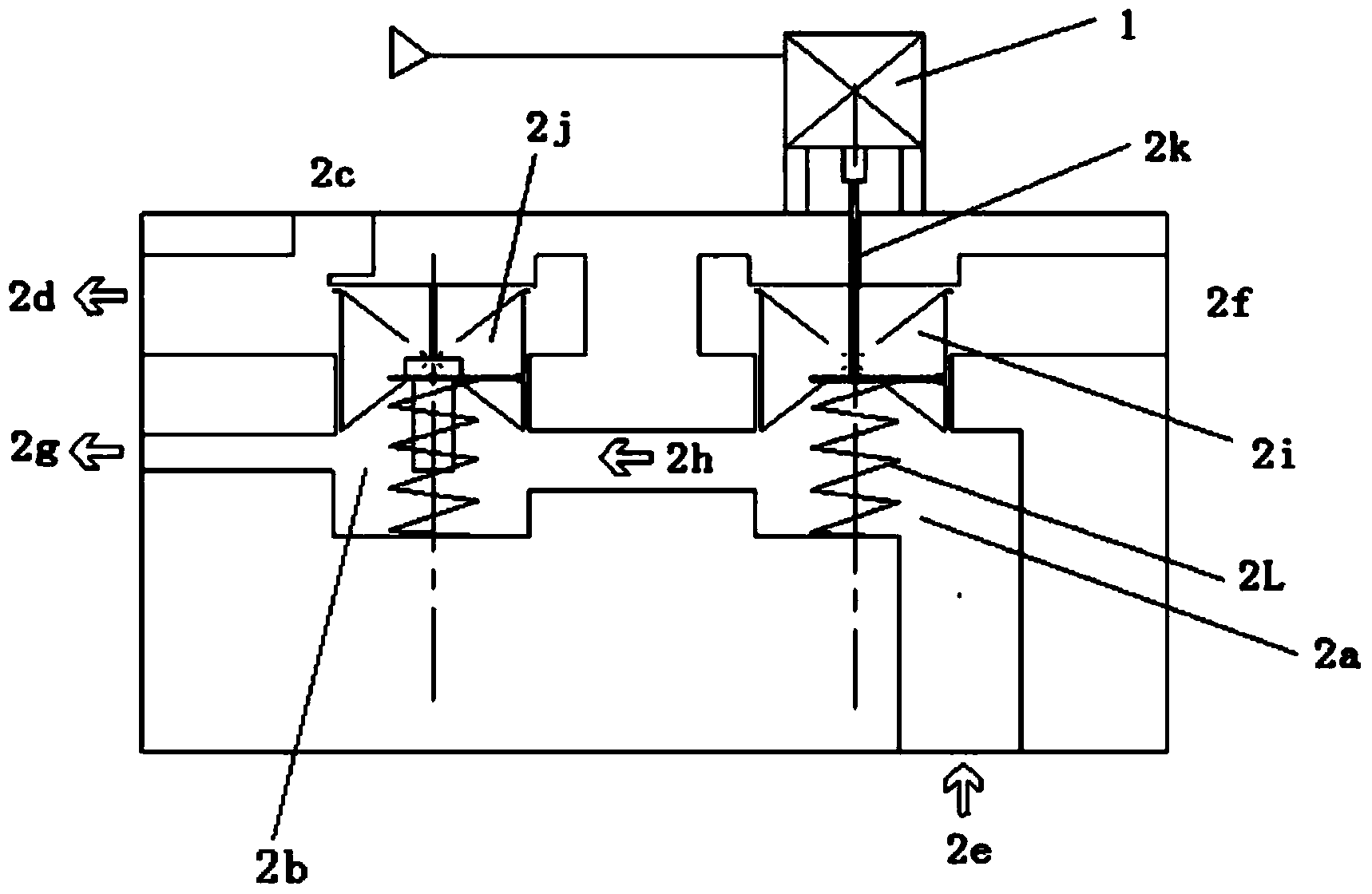

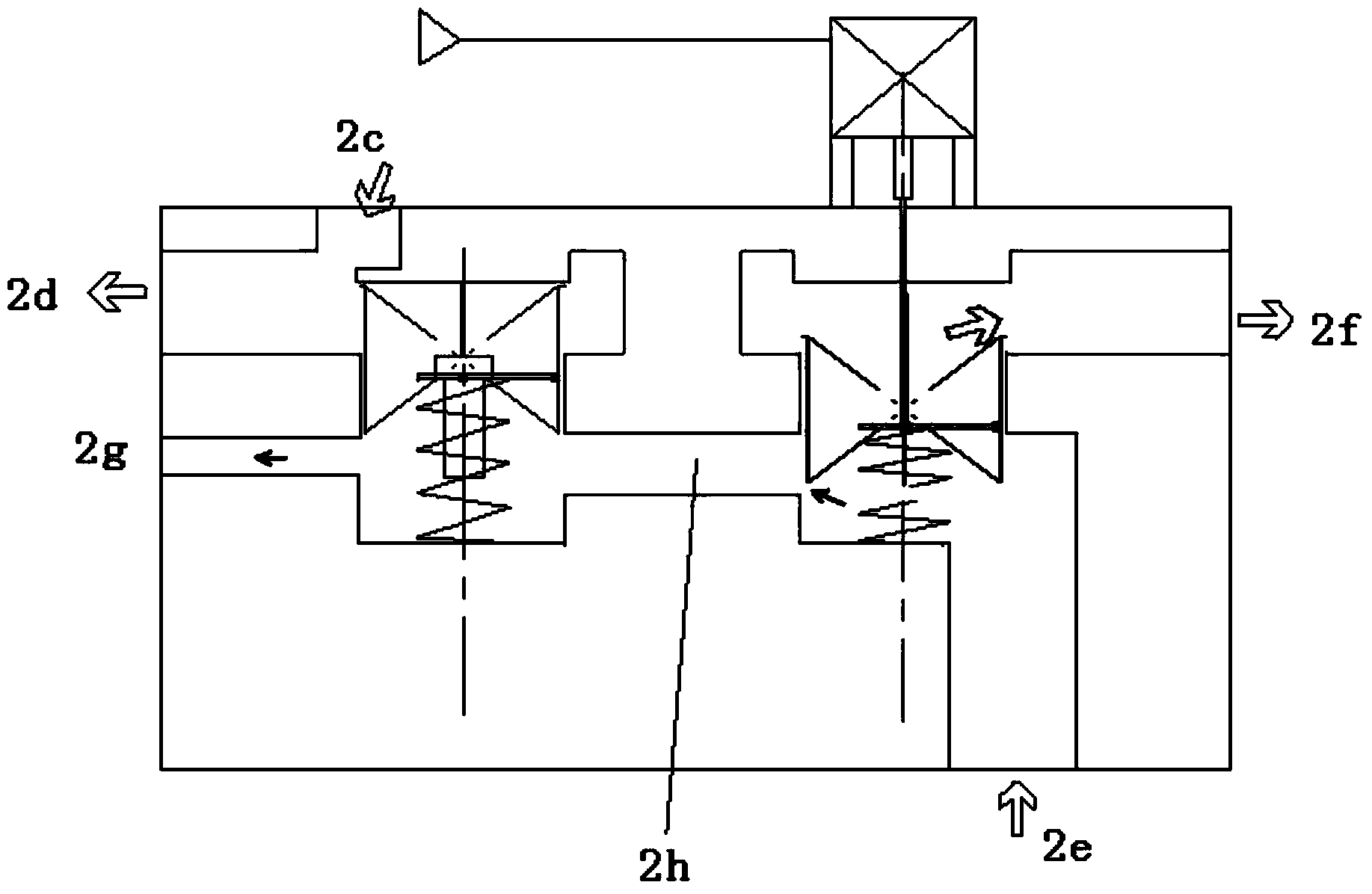

[0010] Embodiment: The present invention comprises radiator 8, engine 9, transmission 10, water pump 6, retarder 11 and heat exchanger 5, and engine 9, transmission 10, retarder 11 and heat exchanger 5 are connected in sequence. It also includes a thermostat 2 provided with a first cavity 2a and a second cavity 2b, the first cavity 2a is provided with a cooling water inlet 2e and a cooling water outlet 2f, the second cavity 2b is provided with a hot water inlet 2c, a large circulation interface 2d and a small circulation interface 2g, the first cavity 2a and the second cavity 2b are connected through a connecting pipe 2h, and the first cavity 2a is equipped with There is a first valve 2i used to control the opening and closing of the connecting pipe 2h and the cooling water outlet 2f. The second cavity 2b is provided with a second valve 2j for controlling the opening and closing of the hot water inlet 2c and the small circulation interface 2g. The water outlet of the engine 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com