Mixer system

A mixer system and mixer technology, which are applied in the directions of machines/engines, mufflers, engine components, etc., can solve the problems that the injector cannot accurately realize the function and reduce the efficiency of the mixer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

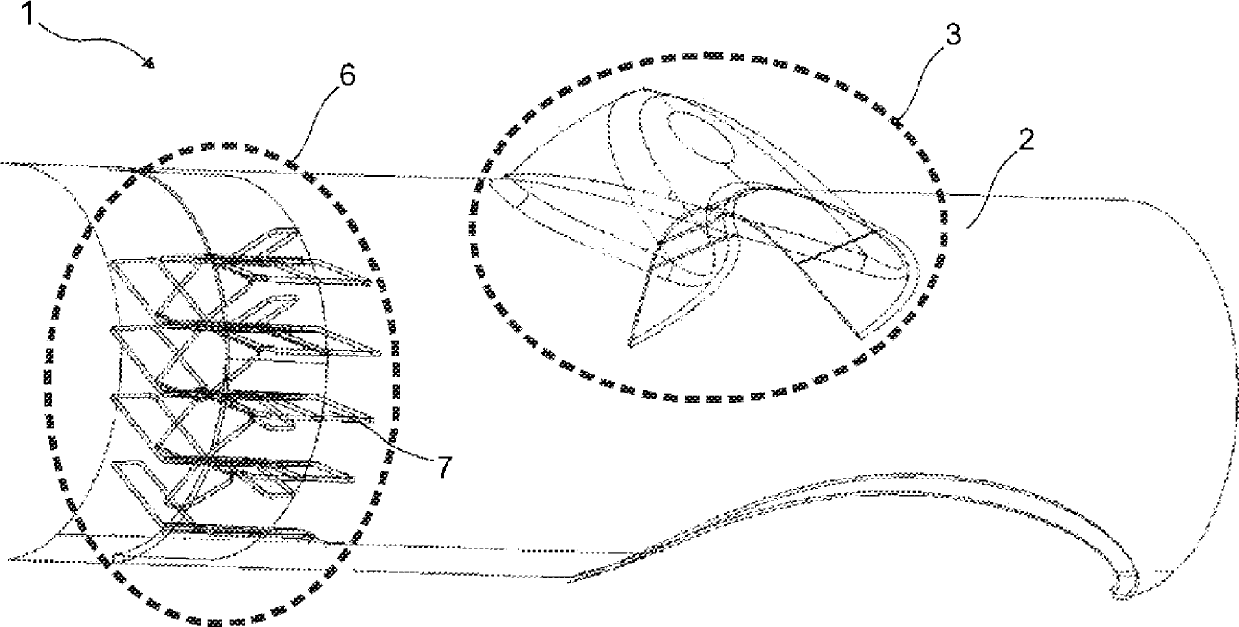

[0020] A mixer system 1 for controlling the behavior of gases injected into the exhaust gas in the exhaust gas, the mixer system basically comprising:

[0021] - at least one exhaust body 2 through which the gases emitted by the fuel burned in the engine of the vehicle are transferred to the external environment,

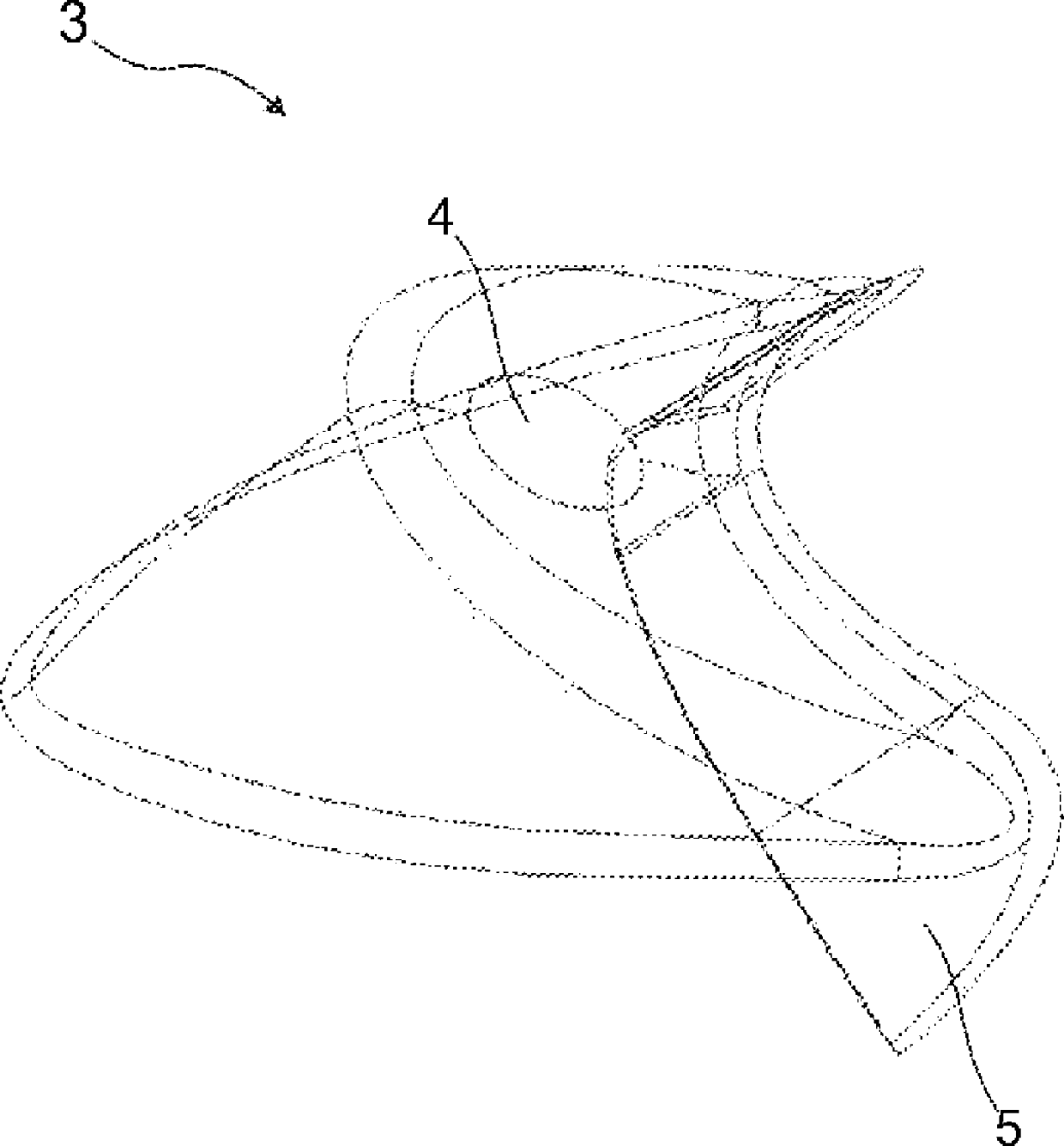

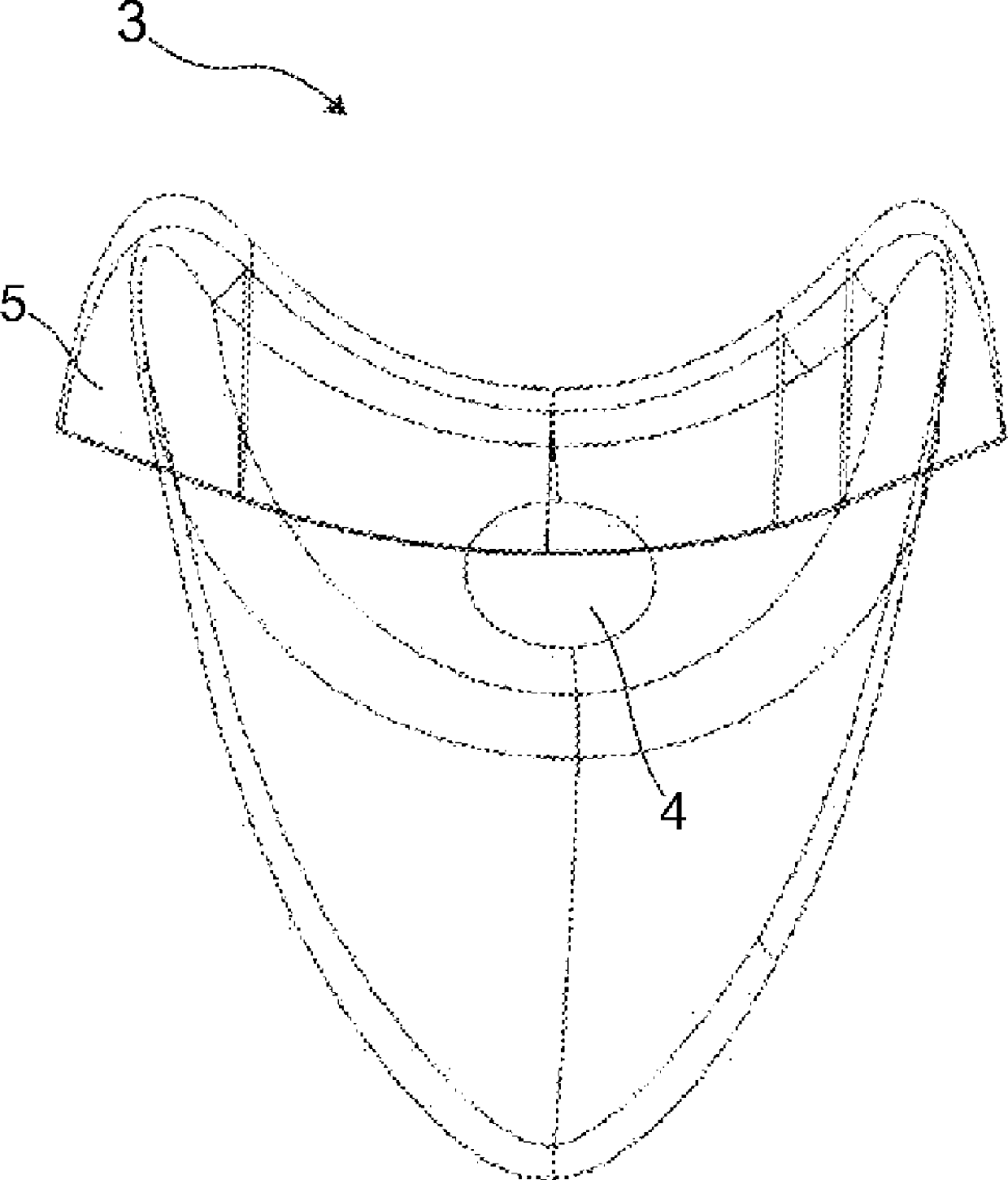

[0022] - at least one injector 3, which is mounted on the exhaust body 2 and makes it possible to reduce the emission of exhaust gases,

[0023] - at least one nozzle 4 enabling the injection of emission-reducing particles to the exhaust body 2,

[0024] - at least one fin 5 enabling the abatement particles leaving the nozzle 4 to be directed in a preferred direction,

[0025] - at least one mixer 6 which enables efficient mixing of the abatement particles injected by the injector 3 with the exhaust fume,

[0026] - At least one baffle 7 which is located in the mixer 6 and which enables the mixture of abatement particles and exhaust smoke to advance in a preferred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com