Mechanical connection pile head using repetitively used precast concrete pile as end plate and manufacturing method of mechanical connection pile head

A precast concrete and mechanical connection technology, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve problems such as floating, tilting, damage, easy deformation of end plates, etc., to improve efficiency, reduce costs, and improve quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing:

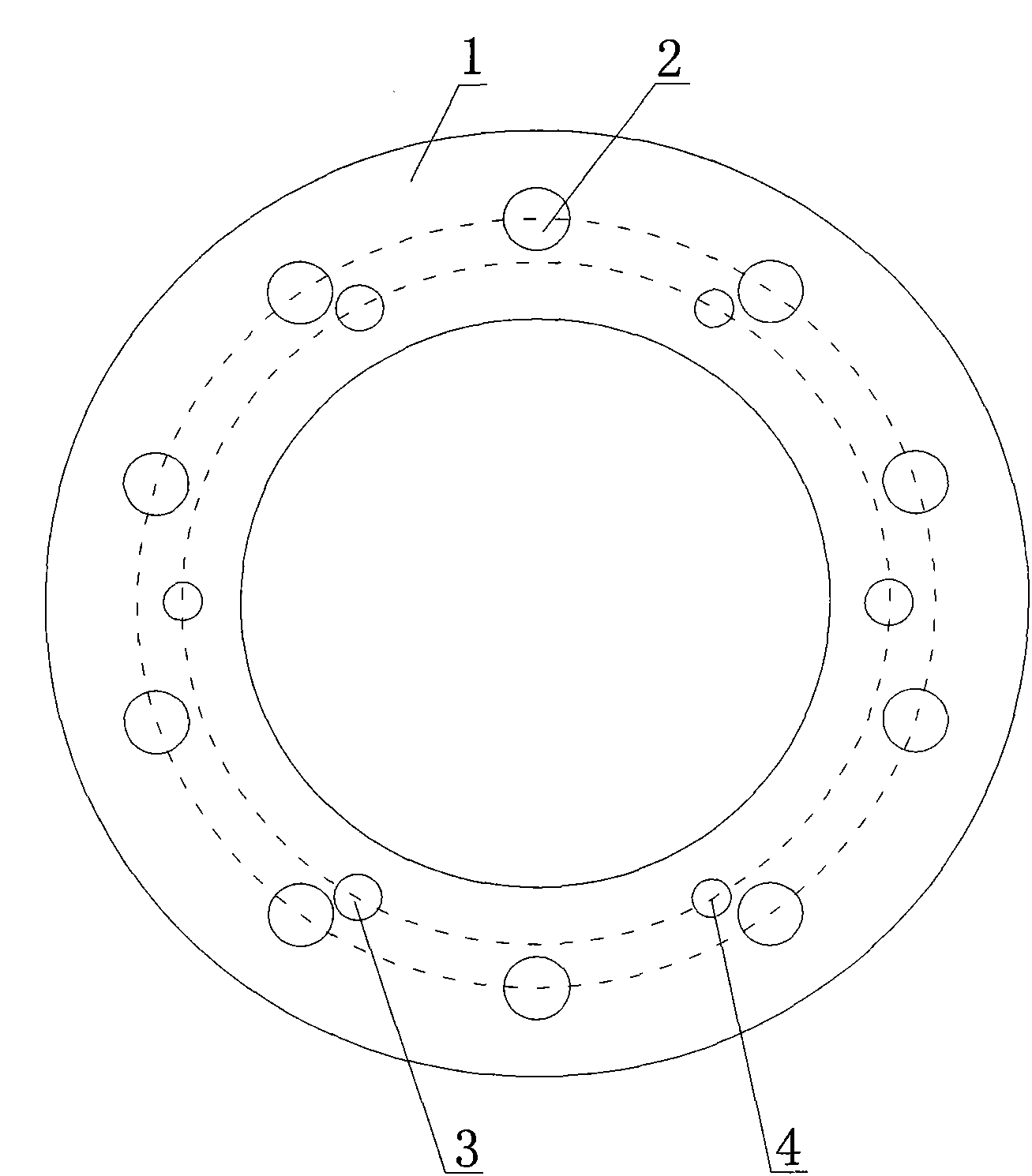

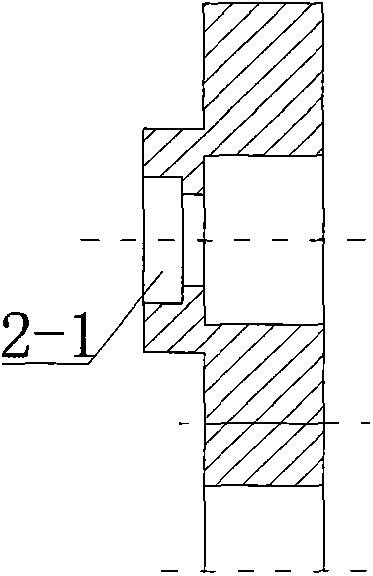

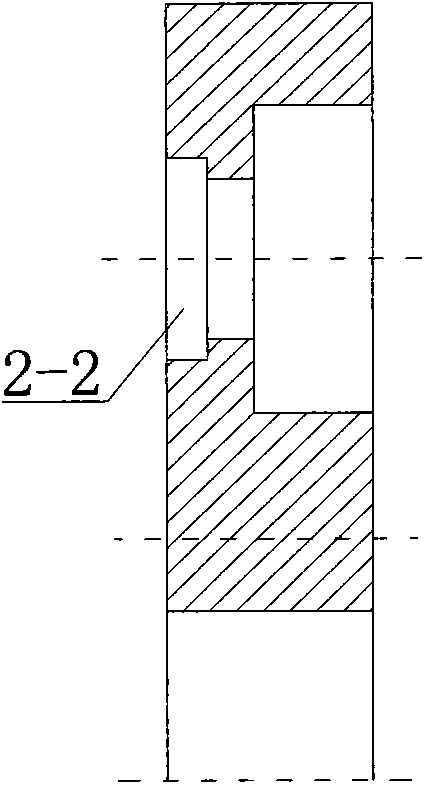

[0033] Such as figure 1 , Figure 5 , Figure 6 , Figure 10 and Figure 11As shown, the end plate 1 of the present invention reuses the mechanical connection pile head of the prefabricated concrete pile, including the end plate 1, the connecting sleeve (composed of the prestressed sleeve 5 and the non-prestressed sleeve 6, not marked in the figure), steel bar 9 and pre-embedded bolts 11, the steel bar 9 is connected with the connecting sleeve, the end plate 1 is connected with the connecting sleeve through high-strength fixing bolts 10, and the end plate 1 is provided with multiple high-strength fixing bolt holes 2 and three pre-embedded bolt holes 3 And three threaded holes 4 of the lifting plate, the embedded bolt holes 3 and the threaded holes 4 of the lifting plate are evenly distributed on the concentric center line of the end plate 1, and the embedded bolt holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com