Method for producing light arene product and clean fuel oil product from catalytic cracking diesel oil

A technology for catalytic cracking of diesel oil and light aromatics, which is applied in the fields of hydrocarbon oil cracking, petroleum industry, and hydrocarbon oil treatment. It can solve problems such as difficulty in meeting clean fuel quality requirements, high content of sulfur and nitrogen compounds, and large loss of extraction solvents. Achieve the effects of long operating period of the device, good activity stability, and good adaptability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

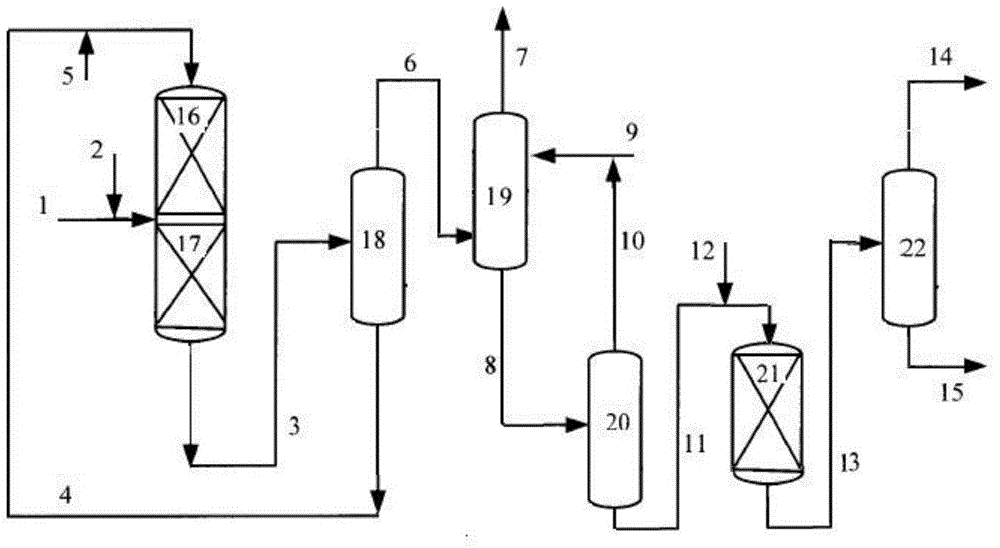

Method used

Image

Examples

Embodiment 1

[0059] According to the method of the invention, catalytic cracking diesel oil is processed to produce light aromatics and clean fuel oil products.

[0060] Catalytically cracked diesel oil is used as raw material to enter the second-stage hydrofinishing reactor of the two-stage hydrocracking-hydrofinishing high-pressure hydrogenation unit in series. The hydrorefining catalyst loading volume of the hydrofinishing section is 200mL, and the hydrocracking catalyst loading volume of the hydrocracking section is 80mL. The hydrorefining product is cut by a continuous distillation unit, and the >355°C distillate oil enters the first stage hydrocracking reactor of the two-stage hydrocracking-hydrofinishing high-pressure hydrogenation device in series, and then passes through the second stage hydrorefining reactor. The reaction temperature is 380°C, the hydrogen partial pressure is 5.5MPa, and the mass space velocity of fresh FCC diesel in the hydrofining section is 1.0h -1 , the hyd...

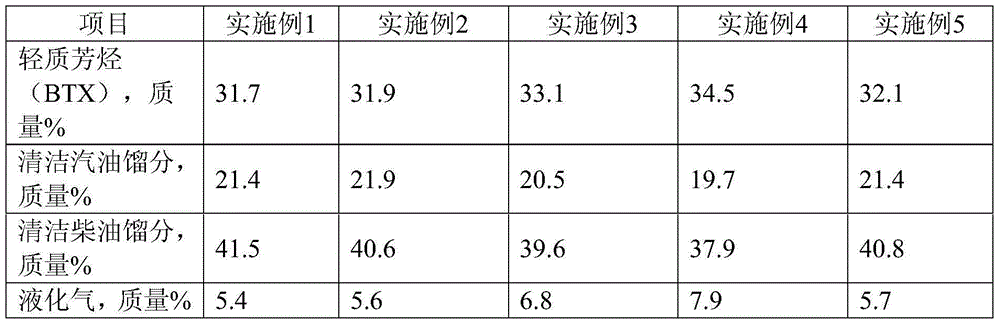

Embodiment 2~5

[0067]The FCC diesel oil was processed sequentially according to the method steps of Example 1, the difference being the selection of reaction conditions and the amount of extraction solvent, the selected test conditions are shown in Table 2.

[0068] The properties of different distillate oil products are shown in Table 3 to Table 5, and the yields of different distillate oil products are shown in Table 6.

[0069] Table 2 Test conditions

[0070]

[0071] Table 3 Properties of extracted oil distillate

[0072] project

Example 1

Example 2

Example 3

Example 4

Example 5

Density (20℃), g / cm 3

0.885

0.881

0.862

0.869

0.886

Sulfur content, μg / g

7

6

6

5

6

Nitrogen content, μg / g

8

9

8

8

7

Aromatics, mass%

93.2

93.4

90.8

91.5

93.6

Polycyclic aromatic hydrocarbons, mass%

10.1

9.4

8.2

8.1

10.3

[0073] Table 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com