Adhesive film for polarizing plate, adhesive composition for the same, polarizing plate comprising the same, and optical display apparatus comprising the same

An adhesive film, polarizing plate technology, applied in the direction of polymer adhesive additives, film/sheet adhesives, non-polymer adhesive additives, etc., can solve the problem of curling, damage, and difficulty in storage. Curing consistency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

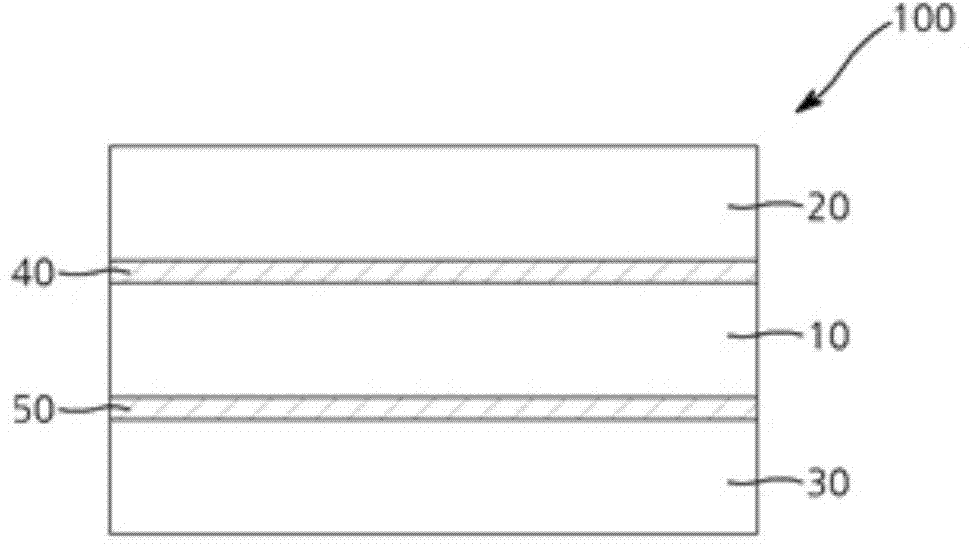

[0024] One aspect of the present invention provides an adhesive film for a polarizing plate, which can be used to attach an optical film to one or both sides of a polarizer. The optical film may include at least one of a protective film and a retardation film.

[0025] The adhesive film may include core-shell type particles including a core and a shell surrounding the core. Due to this structure, the adhesive film can absorb external impacts such as heat and the like, thereby preventing the polarizer or polarizing plate from undergoing cracking.

[0026] The core may comprise an elastomer composed of rubber material. Therefore, the adhesive film can protect the polarizer from external shocks in the external environment or by stress relaxation between the polarizer and the optical film in the case of a sudden increase or decrease in external temperature. Variety.

[0027] The core is composed of a soft elastomer, has a glass transition temperature (Tg) of less than about 25°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com