Forklift hoisting tool and hoisting method thereof

A technology for lifting tools and forklifts, applied in the direction of lifting devices, etc., can solve problems such as high service costs, delay in equipment maintenance, and economic losses of enterprises, and achieve the effect of long service life, reduced economic losses, and cost savings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

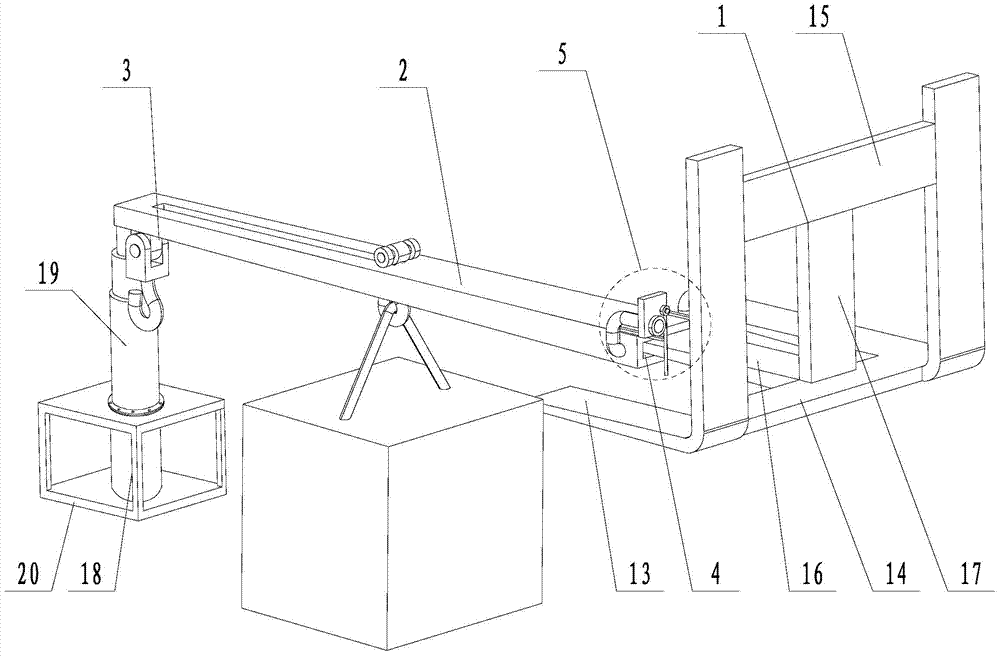

[0028] Embodiment 1: a kind of forklift lifting tool (see attached figure 1 ), including a forklift frame 1 and a boom 2, the boom is provided with a hook 3, the boom is a long strip structure with a rectangular cross-section, one end of the boom is provided with a socket 4, and the forklift frame is plugged into the socket , the forklift frame includes two L-shaped forklift arms 13, the lower connecting plate 14 and the upper connecting plate 15 are fixedly connected between the corner positions and the upper ends of the two L-shaped forklift arms respectively, and the middle position of the lower connecting plate is fixedly connected with a plugboard 16. The board is plugged into the jack of the boom, the connection position between the board and the lower connecting plate is fixedly connected to the limit riser 17, and the upper end of the limit riser is fixedly connected to the upper connection plate. The position of the socket end is fixedly connected with a plug-in limit...

Embodiment 2

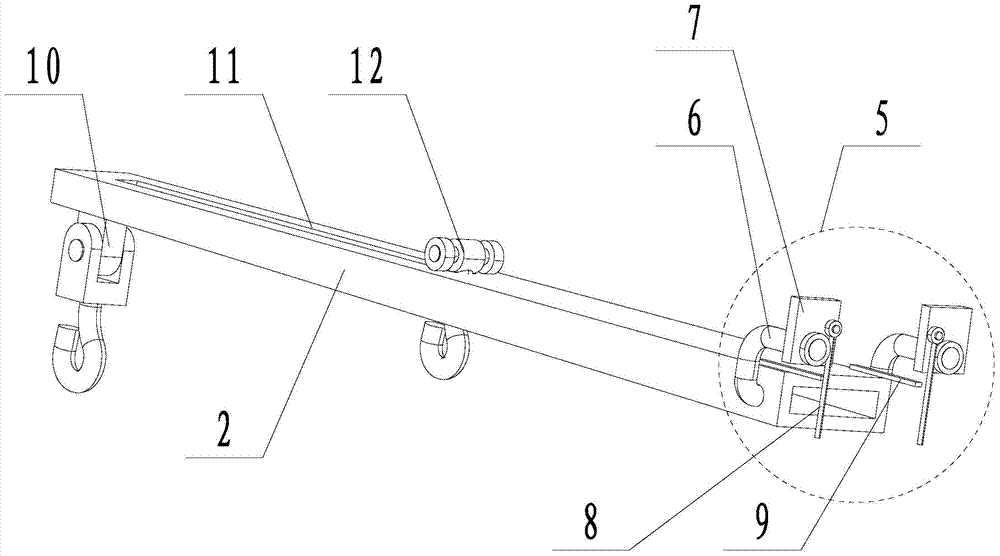

[0030] Embodiment 2: a kind of forklift lifting tool (see attached figure 2 ), its structure is similar to embodiment 1, the main difference lies in the structure of the boom, in this embodiment the boom is in an H-shaped structure, and the H-shaped boom includes a left arm 21, a right arm 22, connected to the left arm and the right arm Between the arm lever 23, one end on the same side of the left arm and the right arm is respectively inserted on the forklift frame and is fixedly connected with a plugging limit mechanism at the insertion position, and the other end on the same side of the left arm and the right arm The support arm 24 is fixedly connected, and the left arm, the right arm, and the arm bar are all provided with interconnected chutes, which can be slidably connected to the movable suspension hook in the chute. When the boom with H-shaped structure is plugged into the forklift frame, the left arm and the right arm can be respectively plugged into two different fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com