Mildew-resistant and antibacterial nano-silver decorative laminated board

An anti-mildew, anti-bacterial and nano-silver technology, applied in the field of nano-materials, can solve the problem of failing to give full play to the anti-mildew and anti-bacterial effect of nano-silver, and achieve the effect of maintaining adhesion, improving adhesion, and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

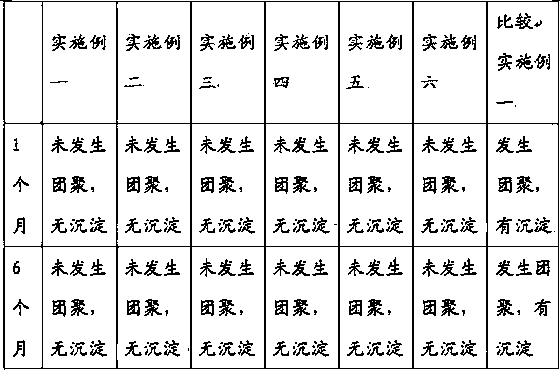

Examples

Embodiment 1

[0040] Preparation of nano silver:

[0041] Add sodium dodecylsulfonate solution and fatty alcohol polyoxyethylene ether sulfate salt solution to silver nitrate aqueous solution to obtain a mixed solution, the molar ratio of sodium dodecylsulfonate to silver nitrate is 2:1; The mol ratio of oxyethylene ether sulfate ester salt and silver nitrate is 2:5;

[0042]Heat the mixture to 45°C, add dicyclohexane-18-crown-6 and sodium borohydride to the mixture while stirring, heat to 70°C, and keep stirring for 5 minutes; dicyclohexane-18-crown The molar ratio of -6 to silver nitrate is 1:1; the molar ratio of sodium borohydride to silver nitrate is 0.5:1, and the pH value is controlled to be 8 to obtain nano silver.

[0043] Preparation of nano silver aqueous solution:

[0044] Dissolve in deionized water with deionized water as solvent, nano silver as solute, acrylic resin as complexing agent and stabilizer in deionized water, then add dispersant and first reducing agent to form a...

Embodiment 2

[0058] Preparation of nano silver:

[0059] Add sodium dodecylsulfonate solution and fatty alcohol polyoxyethylene ether sulfate sodium solution to silver nitrate aqueous solution to obtain a mixed solution, the molar ratio of sodium dodecylsulfonate to silver nitrate is 3:1; The mol ratio of oxyethylene ether sulfate ester salt and silver nitrate is 3:5;

[0060] Heat the mixture to 55°C, add dicyclohexane-18-crown-6 and potassium borohydride to the mixture while stirring, heat to 85°C, and keep stirring for 8 minutes; dicyclohexane-18-crown The molar ratio of -6 to silver nitrate is 1-2:1; the molar ratio of potassium borohydride to silver nitrate is 0.5-1:1, and the pH value is controlled to be 8-9 to obtain nano silver.

[0061] Preparation of nano silver aqueous solution:

[0062] Using deionized water as solvent, nano silver as solute dissolved in deionized water, acrylic resin as complexing agent and stabilizer dissolved in deionized water, then adding dispersant and ...

Embodiment 3

[0074] Preparation of nano silver:

[0075] Add sodium dodecylsulfonate solution and fatty alcohol polyoxyethylene ether sulfate sodium solution into silver nitrate aqueous solution to obtain a mixed solution, the molar ratio of sodium dodecylsulfonate to silver nitrate is 2.5:1; The molar ratio of oxyethylene ether sulfate ester salt to silver nitrate is 1:2;

[0076] Heat the mixture to 50°C, add dicyclohexane-18-crown-6 and sodium metaphosphate to the mixture while stirring, heat to 75°C, and keep stirring for 6 minutes; dicyclohexane-18-crown The molar ratio of -6 to silver nitrate is 1.5:1; the molar ratio of sodium metaphosphate to silver nitrate is 0.8:1, and the pH value is controlled to be 8.5 to obtain nano silver.

[0077] Preparation of nano silver aqueous solution:

[0078] Using deionized water as solvent, nano silver as solute dissolved in deionized water, acrylic resin as complexing agent and stabilizer dissolved in deionized water, then adding dispersant and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com