Forming die and forming method for square pipe end part closing-in of diagonal bar

A technology for forming molds and diagonal struts, which is applied to forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as affecting appearance quality and welding quality, labor-consuming and time-consuming forming effects, and difficulty in ensuring the shape of diagonal struts. To achieve the effect of controllable and consistent length, conducive to welding operation, and ensure consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further explain the technical means and functions adopted by the present invention to achieve the intended purpose of the invention, the specific embodiments, structures, features and functions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

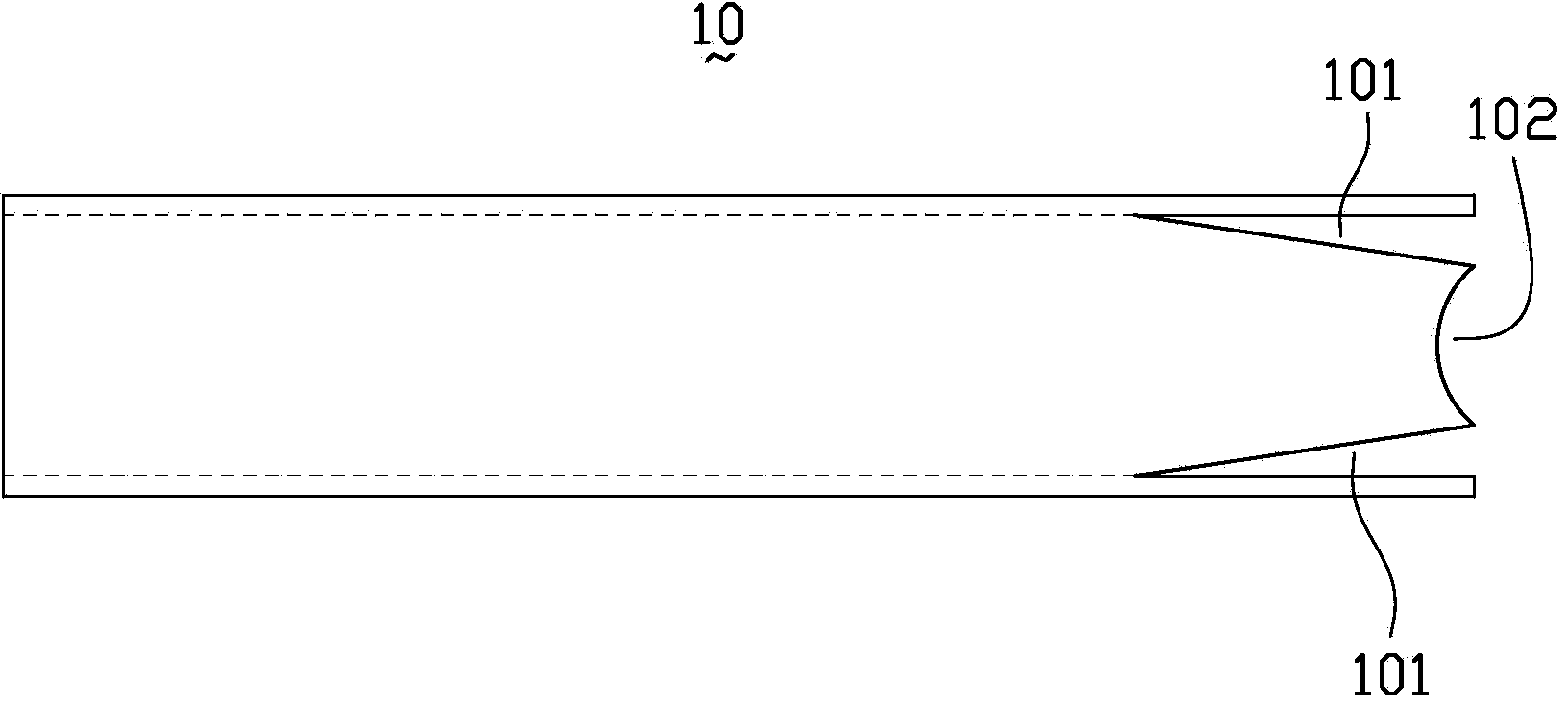

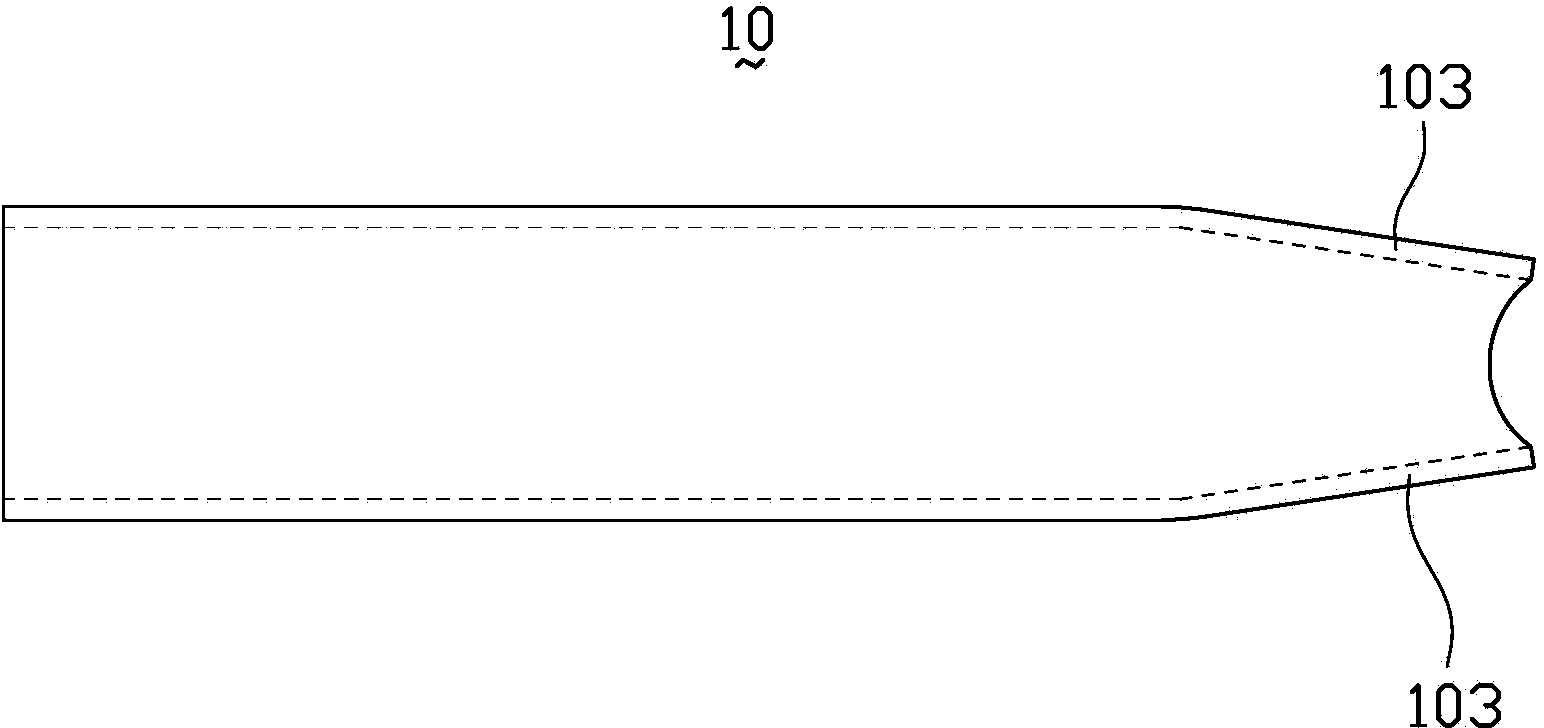

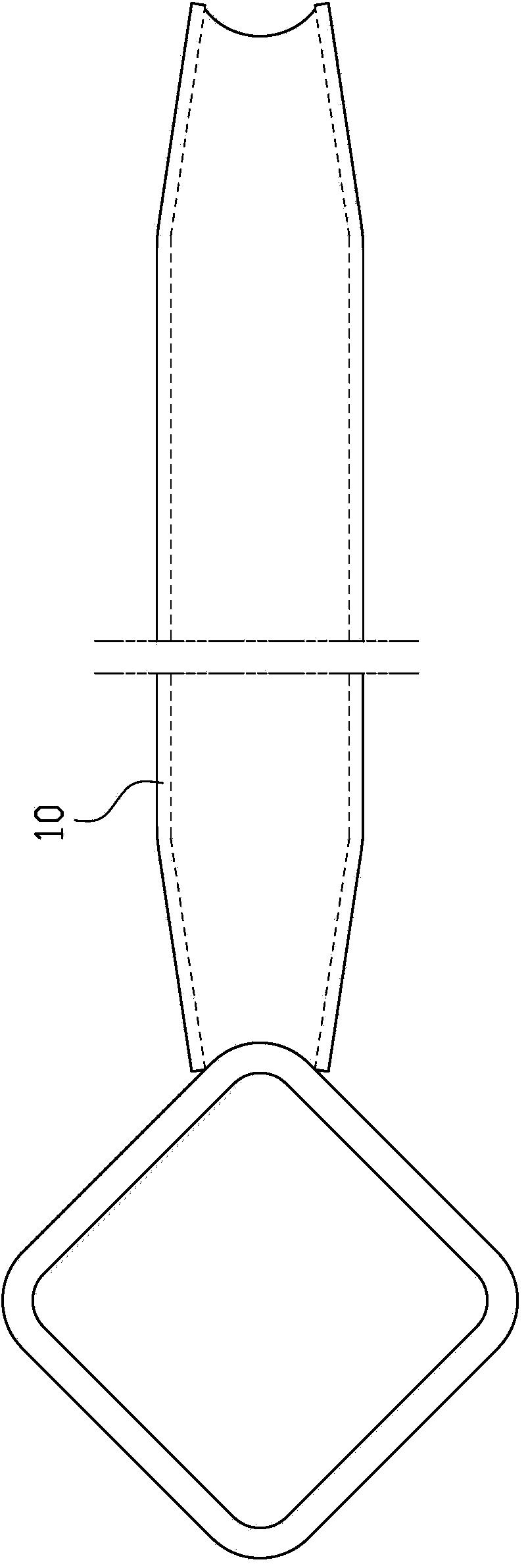

[0044] Please refer to Figure 4 to Figure 6 , the forming mold for closing the end of the diagonal brace square tube according to the embodiment of the present invention is used to close the end of the diagonal brace square tube, for example, the end of the diagonal brace square tube of the standard section of the tower crane Closing molding. Please refer to Figure 10 , the diagonal brace square tube 70 includes a first side wall 701 and a second side wall 702 that are oppositely arranged, and a third side wall 703 and a fourth side that are respectively connected to the first side wall 701 and the second side wall 702 and are opposi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com