Preparation method for solid-phase micro-extraction fiber bundle

A technology for extracting fibers and fibers, which is applied in the field of preparation of solid-phase microextraction fiber bundles, can solve the problems of prolonging the adsorption and analysis time, affecting the service life, reducing the mass transfer speed, etc., achieving high extraction capacity, improving extraction speed, and method easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Preparation of a single SPME fiber based on the overall material: the monomer mixture (containing 20% octadecyl methacrylate, 79.5% divinylbenzene and 0.5% azobisisobutyronitrile) and The porogen (containing n-propanol and cyclohexanol, with a mass percentage of 30% / 70%) was mixed at 30% / 70% to form a uniform solution, and then injected into a quartz crystal with a length of 5cm, an inner diameter of 0.2mm, and a wall thickness of 0.05mm. In the capillary, both ends were sealed, and polymerized at 50°C for 6h. After the polymerization, the 1cm capillary was removed, and the whole material fiber was placed in a Soxhlet extractor, and acetonitrile was used as a solvent for extraction for 4 hours.

[0020] 2) Preparation of SPME fiber bundles: Take 2 fibers prepared in step 1), and bind the 2 fibers together with a sealing film in the capillary part to obtain SPME fiber bundles.

Embodiment 2

[0022] 1) Preparation of a single SPME fiber based on the overall material: the monomer mixture (containing 60% vinylpyridine, 39% divinylbenzene and 1.0% benzoyl peroxide) and porogen (containing positive propanol and 1,4-butanediol (mass percentage is 50% / 50%) mixed at 40% / 60% to form a uniform solution, and then injected into a quartz capillary with a length of 10cm, an inner diameter of 0.4mm, and a wall thickness of 0.05mm , Sealed at both ends, polymerized at 60°C for 12h. After the polymerization, the 1.5 cm capillary was removed, and the whole material fiber was placed in a Soxhlet extractor, and methanol was used as a solvent for extraction for 8 hours.

[0023] 2) Preparation of SPME fiber bundles: take 3 fibers prepared in step 1), and bind the 3 fibers together with adhesive tape in the capillary part to obtain SPME fiber bundles.

Embodiment 3

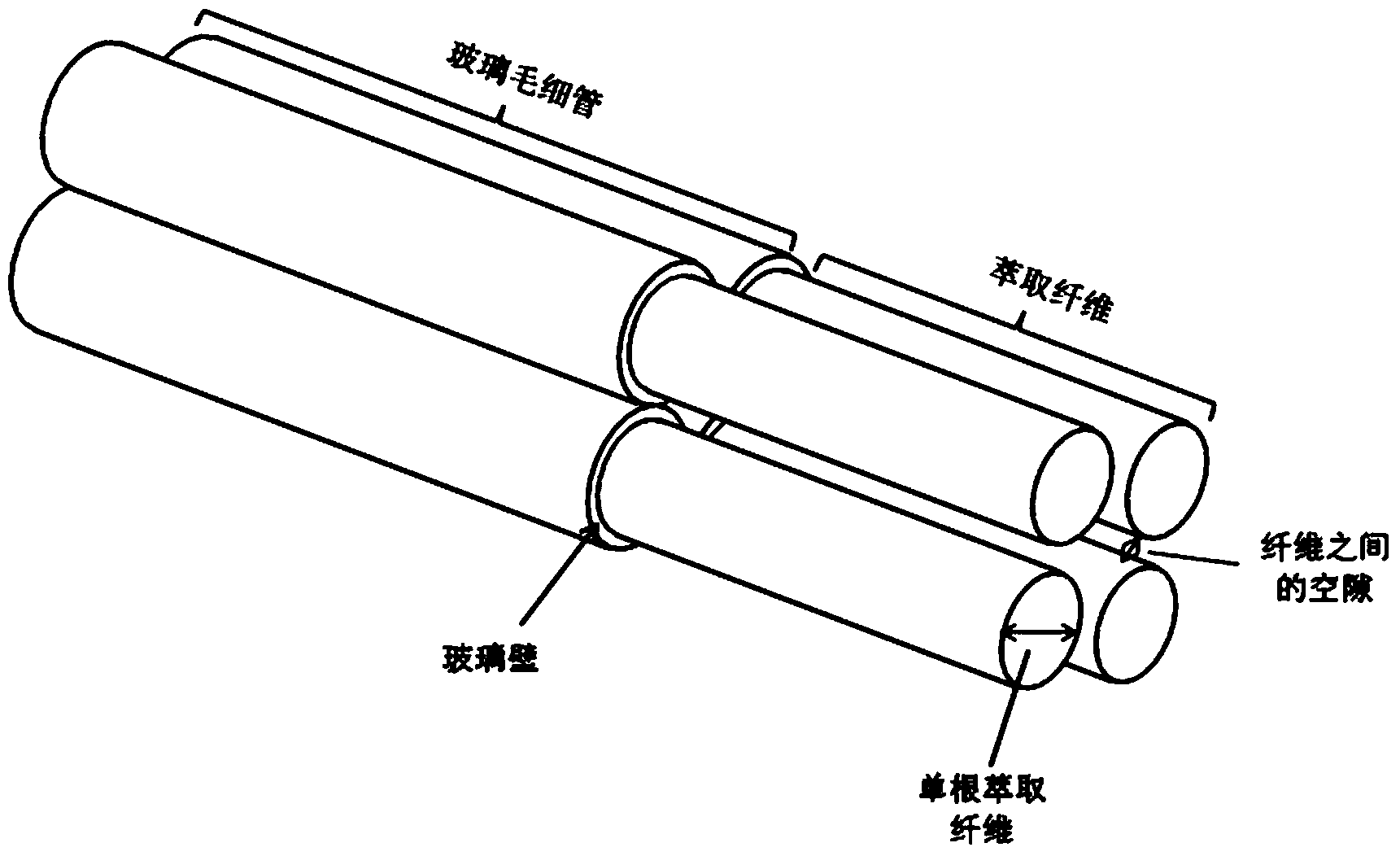

[0025] 1) Preparation of a single SPME fiber based on the overall material: the monomer mixture (containing 35% vinylimidazole, 63% divinylbenzene and 2.0% azobisisobutyronitrile) and porogen (containing n-propanol and 1,4-butanediol (60% / 40% by mass) were mixed into a uniform solution at 60% / 40%, and then injected into a glass tube with a length of 10cm, an inner diameter of 0.5mm, and a wall thickness of 0.1mm In the process, both ends were sealed and polymerized at 70°C for 12h. After the polymerization, the 2cm capillary was removed, and the whole material fiber was placed in a methanol solvent, soaked until no impurities were detected in the liquid. figure 1 It is a physical picture of a single SPME fiber of the overall material.

[0026] 2) Step 2: Preparation of SPME fiber bundles: Take 4 fibers prepared in step 1), and combine the 4 fibers with raw material tape in the capillary part to obtain SPME fiber bundles. figure 1 Schematic diagram of the SPME fiber bundle co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com