Salicylic acid nanostructured lipid carrier and preparation method and application thereof

A technology of nano-structured lipid and salicylic acid, which is used in pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve the problems of strong irritation of salicylic acid, poor water solubility and inconvenience, and achieve improved water solubility and stability. Effectiveness, reduced irritation and allergic skin reactions, convenient formulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

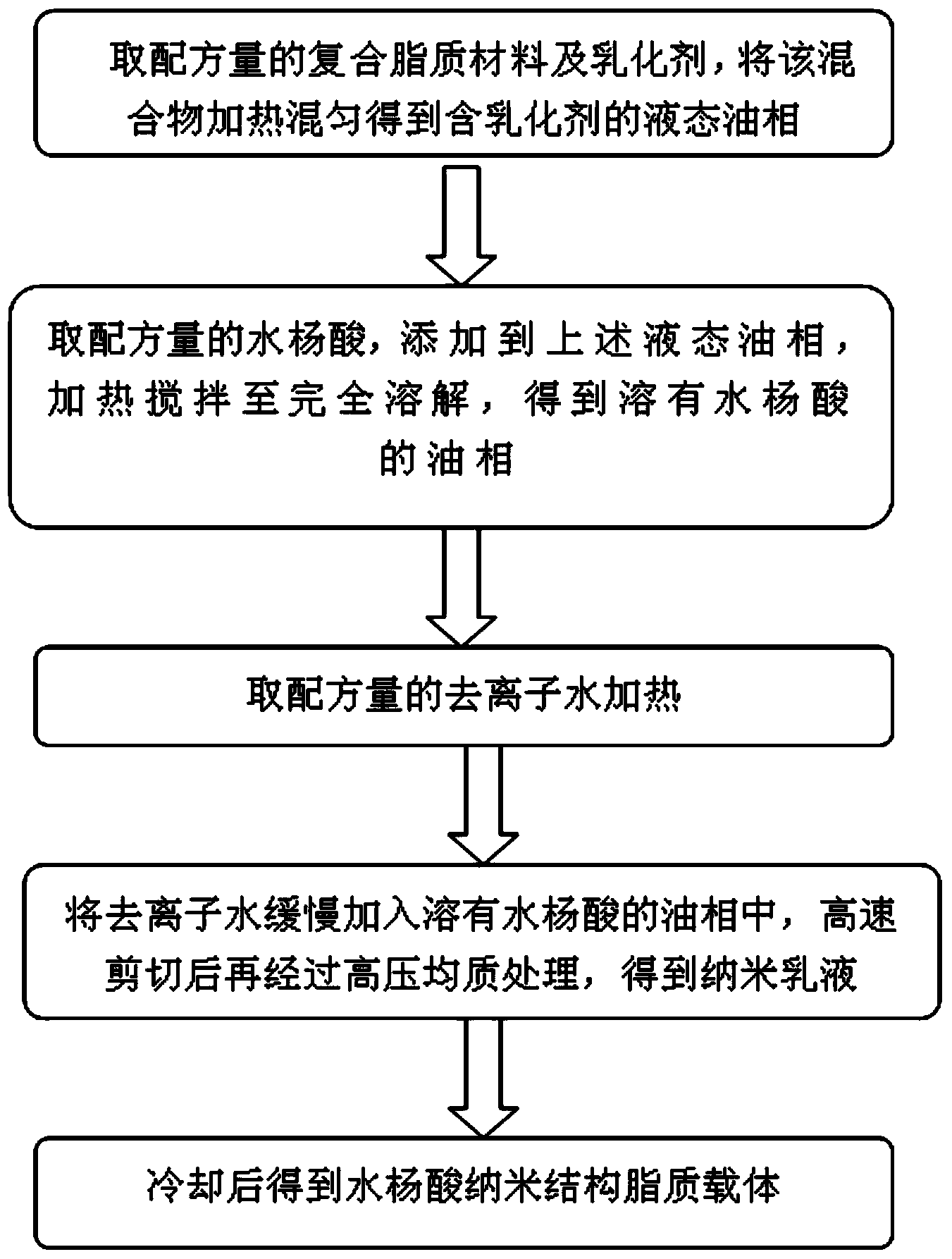

[0048] The preparation method of the above-mentioned salicylic acid nanostructure lipid carrier, such as figure 1 shown, including the following steps:

[0049]Step 1. Take the compound lipid material and emulsifier in the formula amount, heat and mix to obtain a liquid oil phase containing emulsifier at 55°C to 75°C;

[0050] Step 2: Take the formula amount of salicylic acid and add it into the liquid oil phase containing emulsifier in step 1, stir at 55°C to 75°C until completely dissolved, and obtain the oil phase in which salicylic acid is dissolved;

[0051] Step 3, take the deionized water of formula quantity, heat to 55 ℃~75 ℃;

[0052] Step 4. Slowly add deionized water from step 3 to the oil phase in which salicylic acid is dissolved in step 2, and shear at a high speed at 55°C to 75°C, with a shear speed of 10,000 to 13,000rpm and a shear time of 0.5 to 1min , and then through high-pressure homogenization, the homogenization pressure is 400-600 bar, and the number ...

Embodiment 1

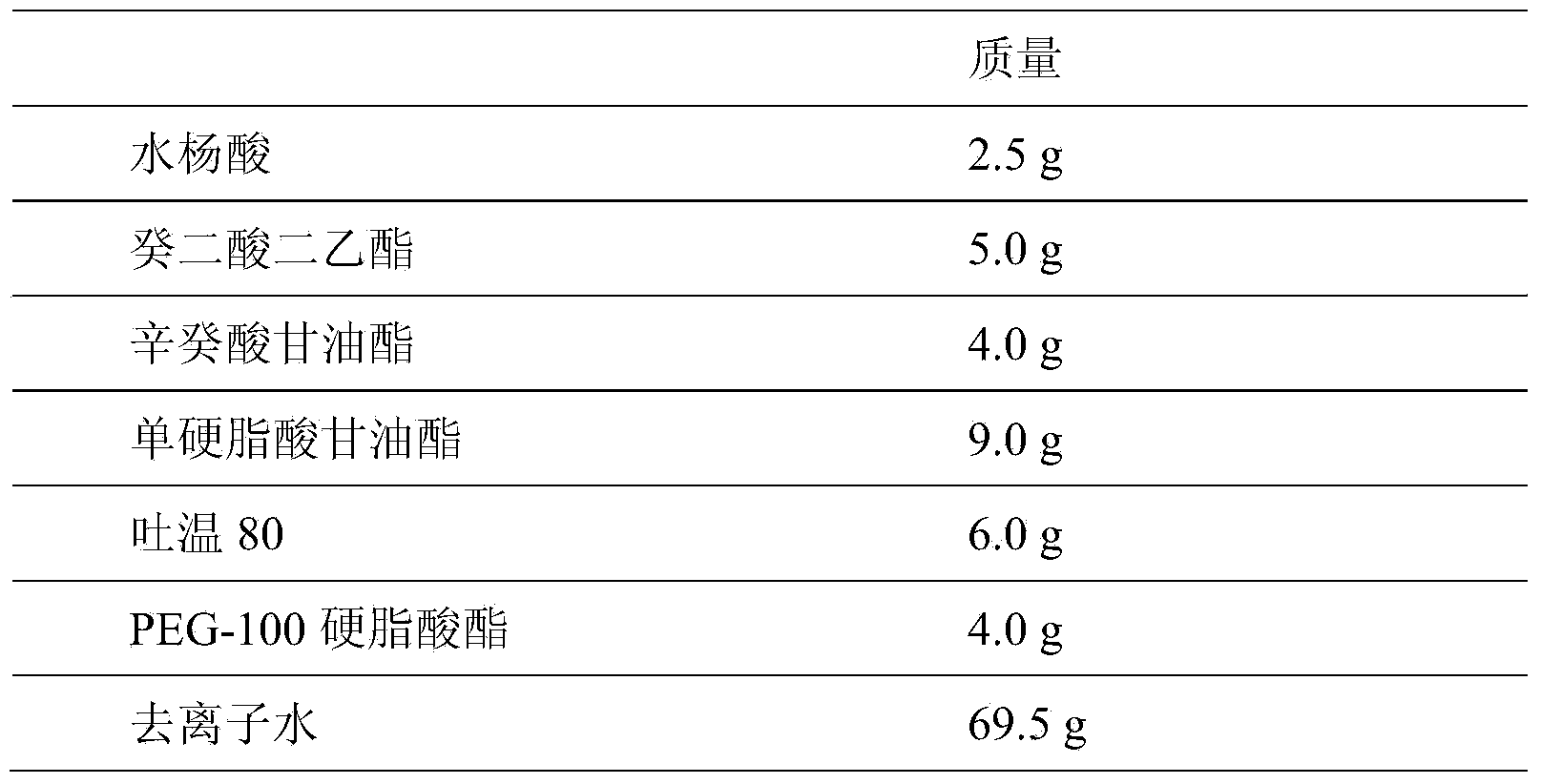

[0056] Composition formula

[0057]

[0058] (1) Accurately weigh 5.0 grams of diethyl sebacate, 4.0 grams of glyceryl caprate, 9.0 grams of glyceryl monostearate, 6.0 grams of Tween 80, and 4.0 grams of PEG-100 stearate. The mixture of lipid material and emulsifier is heated and mixed to obtain a liquid oil phase containing emulsifier at 75°C;

[0059] (2) Accurately weigh 2.5 grams of salicylic acid, add it to the above-mentioned liquid oil phase containing emulsifier, stir at 75°C until completely dissolved, and obtain an oil phase in which salicylic acid is dissolved;

[0060] (3) Accurately weigh 69.5 grams of deionized water, and heat it in a water bath to 75°C;

[0061] (4) Slowly add deionized water into the oil phase dissolved in salicylic acid, shear at a high speed for 0.5min at 75°C, and select a shear speed of 10,000rpm, and then undergo high-pressure homogenization, the homogenization pressure is 600bar, and the number of homogenization For 4 times, obtain t...

Embodiment 2

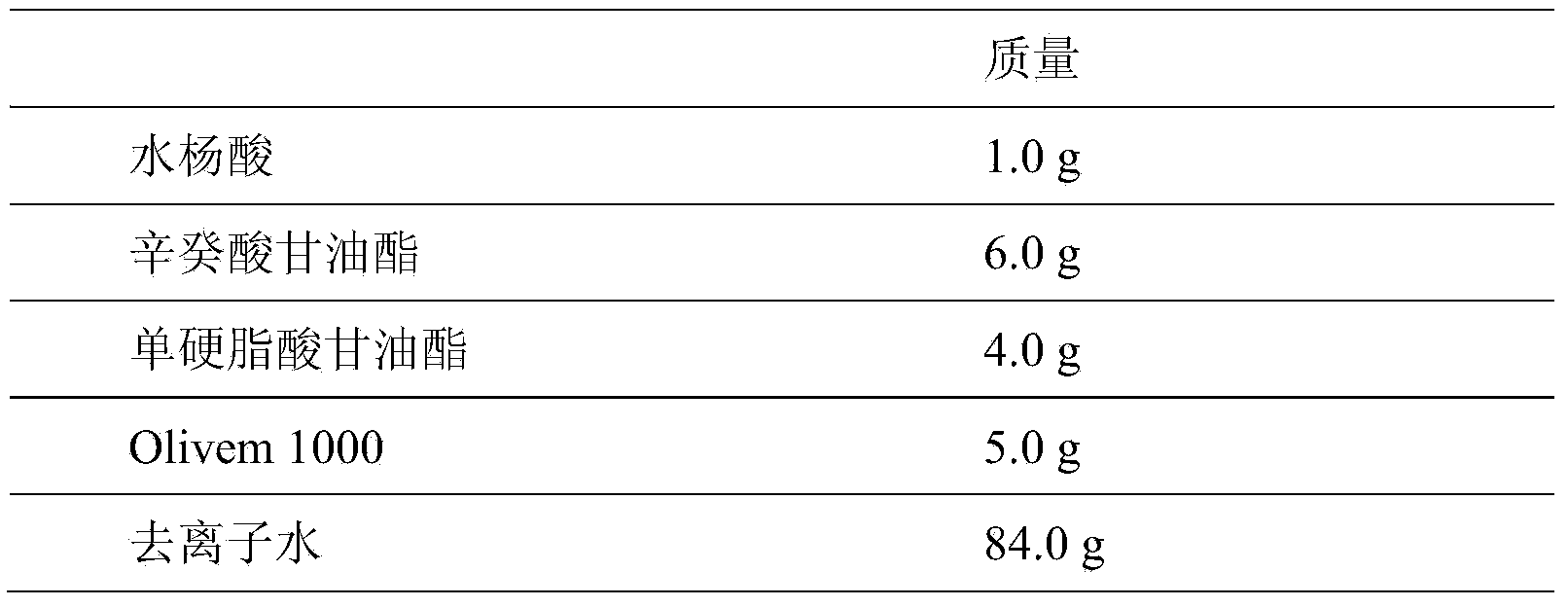

[0065] Composition formula

[0066]

[0067] (1) Accurately weigh 6.0 grams of glyceryl caprylate, 4.0 grams of glyceryl monostearate and 5.0 grams of Olivem1000, heat and mix the lipid material and emulsifier mixture to obtain a liquid oil phase containing emulsifier at 75°C;

[0068] (2) Accurately weigh 1.0 g of salicylic acid, add it to the above-mentioned liquid oil phase containing emulsifier, stir at 75°C until completely dissolved, and obtain an oil phase in which salicylic acid is dissolved;

[0069] (3) Accurately weigh 84.0 grams of deionized water, and heat it in a water bath to 75°C;

[0070] (4) Slowly add deionized water into the oil phase dissolved in salicylic acid, shear at a high speed for 1min at 75°C, and select a shear speed of 10,000rpm, and then undergo high-pressure homogenization, with a homogenization pressure of 400bar, and the number of homogenizations is 3 times to obtain nanoemulsion;

[0071] (5) Stir and cool the nanoemulsion in an ice bat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com