Method for producing instant rice noodles by adding annealed corn starch

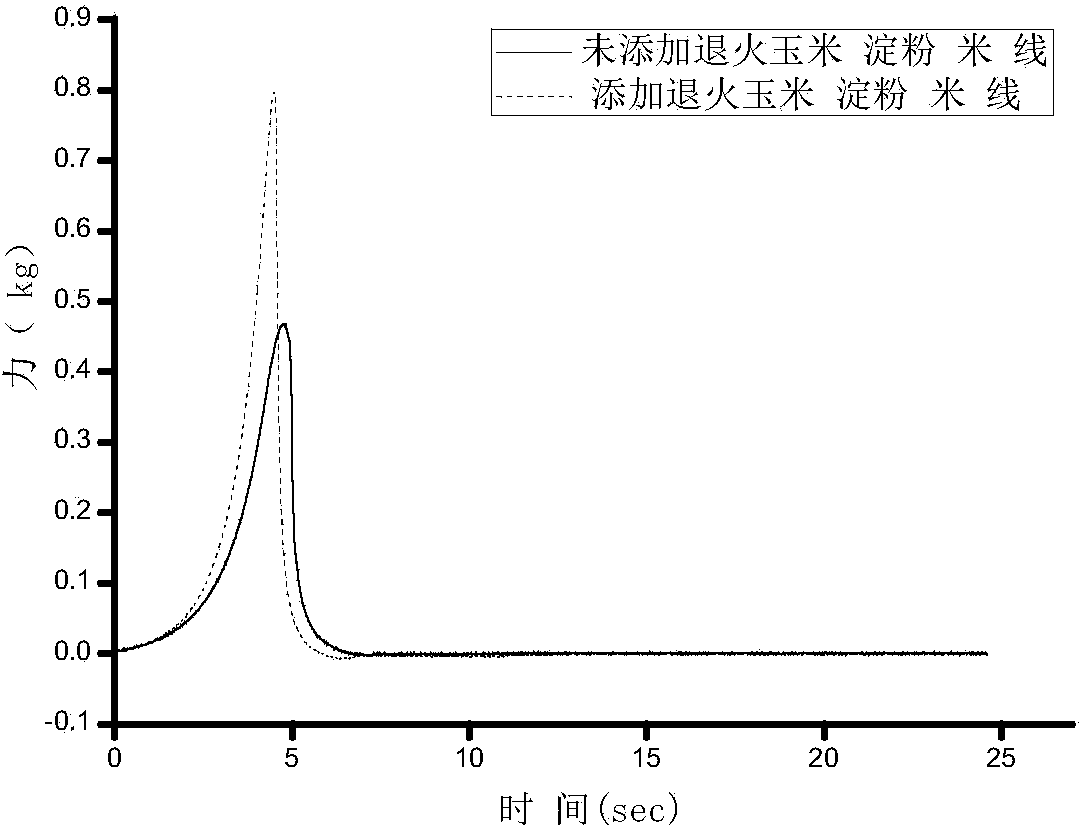

A corn starch and annealing technology, applied in the fields of application, food preparation, food science, etc., can solve the problems of impermeable soaking, not easy to taste, and long rehydration time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below through specific embodiments.

[0020] Cornstarch and early indica rice in the examples are commercially available conventional products.

[0021] The manufacturer and model of the physical property tester: British SMS Company, TA.XT Plus; the manufacturer and model of the electric heating constant temperature blast drying oven: Shanghai Yiheng Scientific Instrument Co., Ltd., DHG-9140A; the manufacturer and Model: Shanghai Hetai Instrument Equipment Co., Ltd., Millipore RM-220; manufacturer and model of air bath constant temperature oscillator: Jiangsu Jincheng Guosheng Experimental Instrument Factory, CHA-S; manufacturer and model of single-chamber vacuum packaging machine: Shanghai Avan Lao Machinery Co., Ltd., DZ-400.

[0022] 1. Annealing

[0023] Add pure water to cornstarch, the mass volume ratio of cornstarch and pure water is 1g:4mL, anneal at 50°C for 3 days after sealing, filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com