Refreshing and eyesight improving type peony seed blend oil and preparation method

A technology of peony seed oil and peony seed, which is applied in the field of blended oil, can solve the problems of low utilization rate of peony seed and preparation of peony seed blended oil, etc., and achieve the effects of being suitable for large-scale industrial production, reducing production costs, and comprehensive and reasonable nutritional components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing peony seed blend oil for clearing the mind and improving eyesight, comprising the following steps:

[0035] Step 1: Peony seeds free from diseases and insect pests are shelled, soaked in water for 5~10 hours, drained, frozen at -20~-10°C for 8~10 hours, and then crushed at this temperature into particles with a particle size of 0.5~1mm. peony seeds, spare;

[0036] Step 2: Put the peony seeds prepared in Step 1 into a microwave drying oven, and vacuum-dry them for 30-60 minutes under the condition of a microwave drying power of 6-9W / g, then stop the microwave drying, and use a heat pump dehumidification system for cyclic dehumidification and drying for 60 minutes. ~90 minutes, stop the heat pump dehumidification, and then microwave drying for 20-40 minutes, stop the microwave drying, and use the heat pump dehumidification system to dehumidify and dry the peony seeds again until the water content drops below 5%, and then set aside;

[0037] Step 3...

Embodiment 1

[0048] A method for preparing peony seed blend oil for clearing the mind and improving eyesight, comprising the following steps:

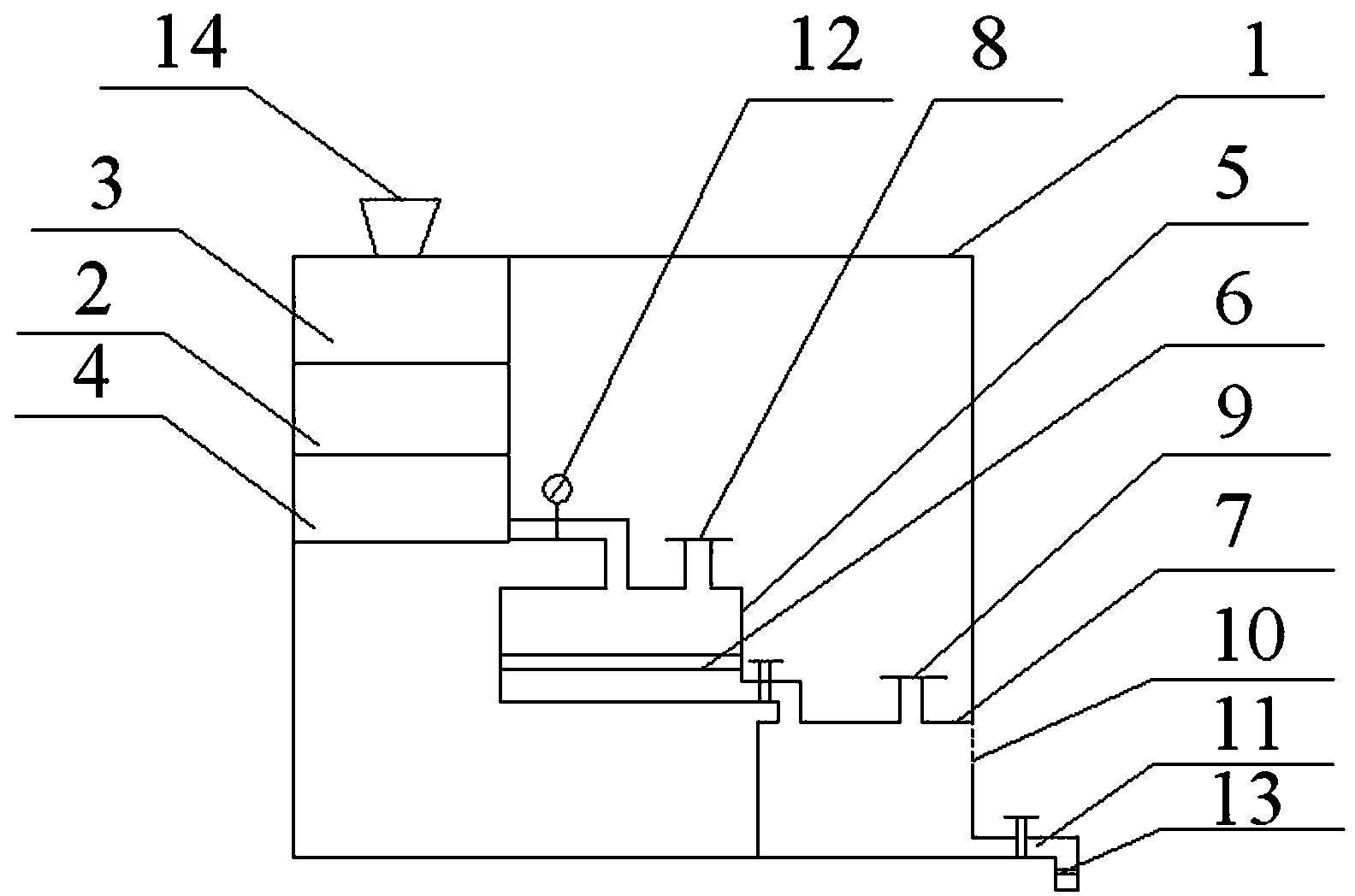

[0049] Step 1: Peony seeds free from diseases and insect pests are shelled, soaked in water for 5 hours in a water tank, drained, frozen in a freezer at -10°C for 8 hours, and then fed into the pulverizer 3 from the feed port 14 at this temperature for crushing Peony grains with a particle size of 0.5mm are used for subsequent use;

[0050] Step 2: Put the peony seeds prepared in Step 1 into the microwave drying box 2, and vacuum-dry them for 30 minutes under the condition of microwave drying power 6W / g, then stop the microwave drying, use the heat pump dehumidification system to carry out circulating dehumidification and drying for 60 minutes, and stop the heat pump dehumidification , after another 40 minutes of microwave drying, stop the microwave drying, and use the heat pump dehumidification system to dehumidify and dry the peony seeds again un...

Embodiment 2

[0057] A method for preparing peony seed blend oil for clearing the mind and improving eyesight, comprising the following steps:

[0058] Step 1: Peony seeds free from diseases and insect pests are shelled, soaked in water for 10 hours in a water tank, drained, frozen in a freezer for 10 hours at -20°C, and then fed into the pulverizer 3 from the feed port 14 at this temperature for crushing Peony grains with a particle size of 1mm are used for subsequent use;

[0059] Step 2: Put the peony seeds prepared in Step 1 into the microwave drying oven 2, and vacuum-dry them for 60 minutes under the condition of microwave drying power 9W / g, then stop the microwave drying, use the heat pump dehumidification system to carry out circulating dehumidification and drying for 90 minutes, and stop the heat pump dehumidification , after another 20 minutes of microwave drying, stop the microwave drying, and use the heat pump dehumidification system to dehumidify and dry the peony seeds again u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com