Non-salient pole electromagnetic speed regulator

An electromagnetic speed regulation, hidden pole technology, applied in electrical components, electromechanical devices, magnetic circuit rotating parts, etc. Wide range, low cost, and the effect of reducing current inrush

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

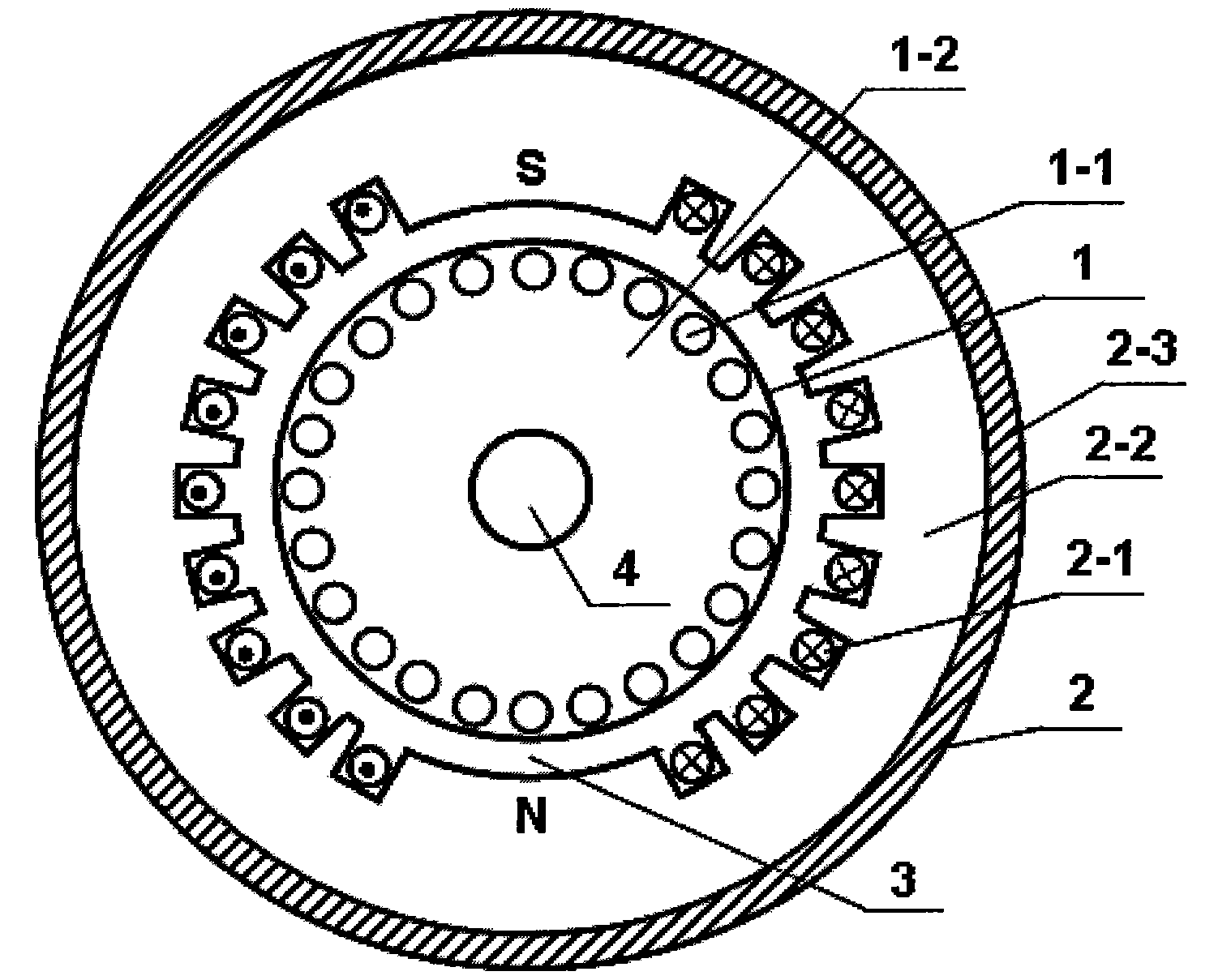

[0023] Refer to attached figure 1 , a hidden pole type electromagnetic speed regulator, characterized in that it includes an inner rotor 1, a hidden pole type outer rotor 2 and an inner rotor shaft 4, and a uniform gas with a fixed size is formed between the inner rotor and the hidden pole type outer rotor. Gap 3.

[0024] The inner rotor 1 includes an inner rotor winding 1-1 and an inner rotor core 1-2, which is the same as the rotor of a traditional AC asynchronous motor, and can be a squirrel-cage type, a wound type or a solid rotor; the inner rotor 1 is set on 4 on the inner rotor shaft, and make a whole with the inner rotor shaft 4.

[0025] The hidden pole type outer rotor 2 includes a distributed outer rotor excitation winding 2-1, a hidden pole type outer rotor core 2-2 and an outer rotor shell 2-3. The distributed outer rotor excitation winding 2-1 adopts copper or aluminum wires, and the hidden pole outer rotor iron core 2-2 adopts silicon steel sheet or alloy stee...

Embodiment 2

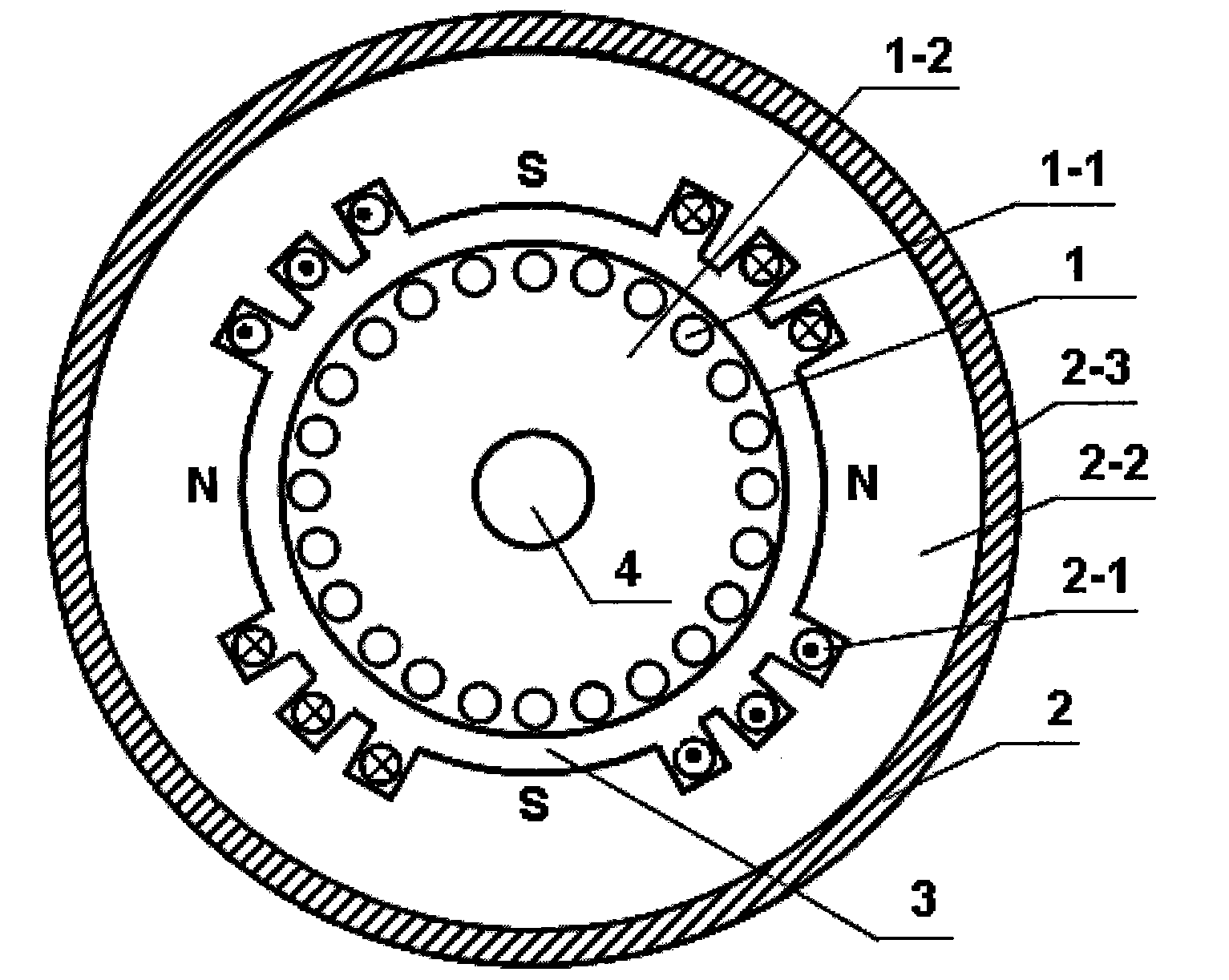

[0027] Refer to attached figure 2 , another embodiment of a hidden pole electromagnetic speed regulator. The two invisible iron core magnetic poles (one pair of poles) of the hidden pole type outer rotor 2 in the first embodiment are increased to four (two pairs of poles), by making the field winding 2-1 at both ends of each invisible iron core magnetic pole The direction of the current is opposite, so that the polarities of the two adjacent invisible iron core poles are opposite, forming a NSNS structure. By analogy, the number of invisible iron core poles can be increased to six (three pairs of poles), eight (four pairs of poles), ten (five pairs of poles), and so on.

Embodiment 3

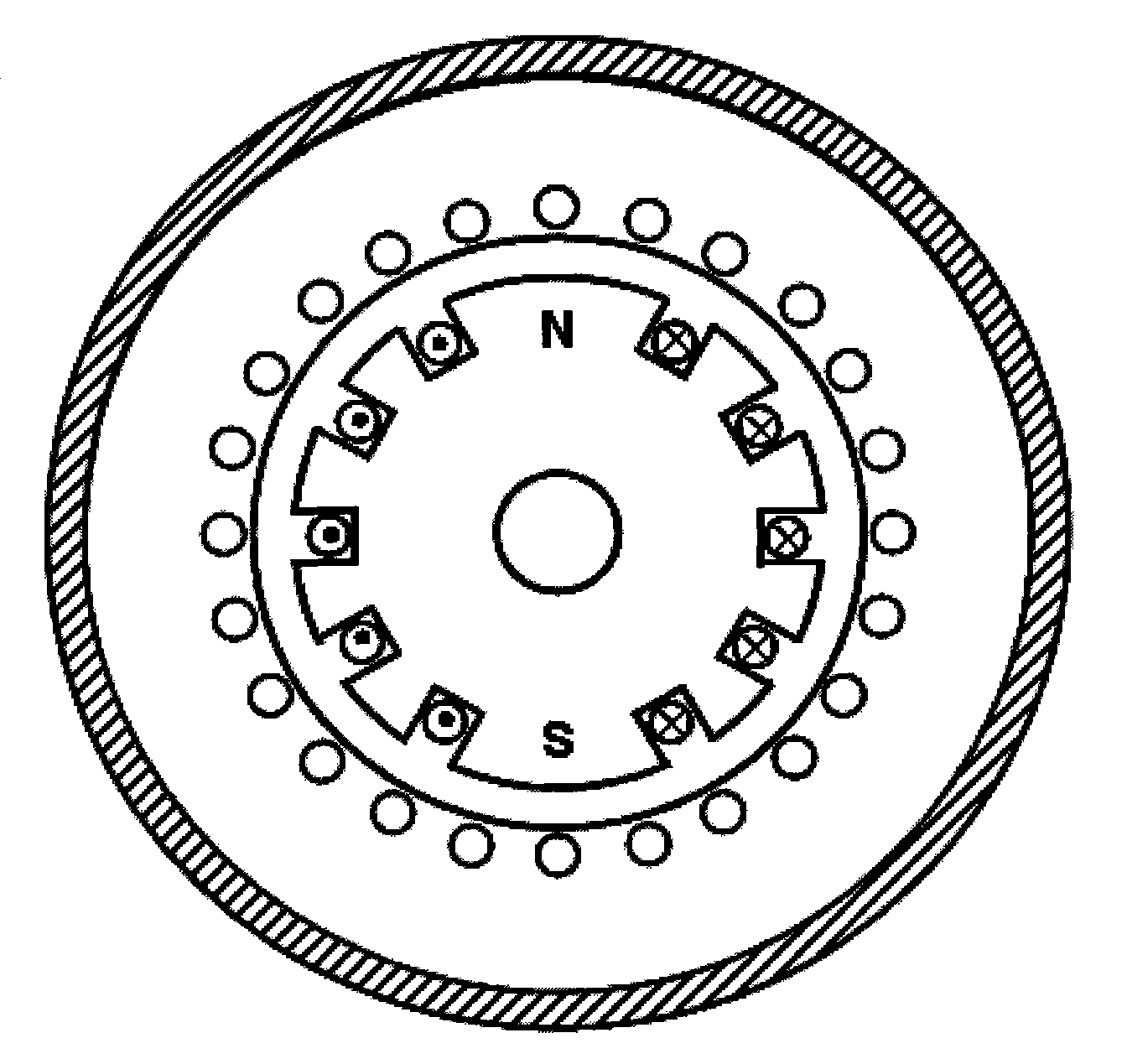

[0029] Refer to attached image 3 , another embodiment of a hidden pole electromagnetic speed regulator. The structures of the inner and outer rotors in Embodiment 1 are interchanged, that is, the outer rotor adopts the rotor structure of a traditional AC asynchronous motor, the inner rotor adopts a hidden-pole structure, and a DC excitation current is passed into the excitation winding of the hidden-pole inner rotor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com