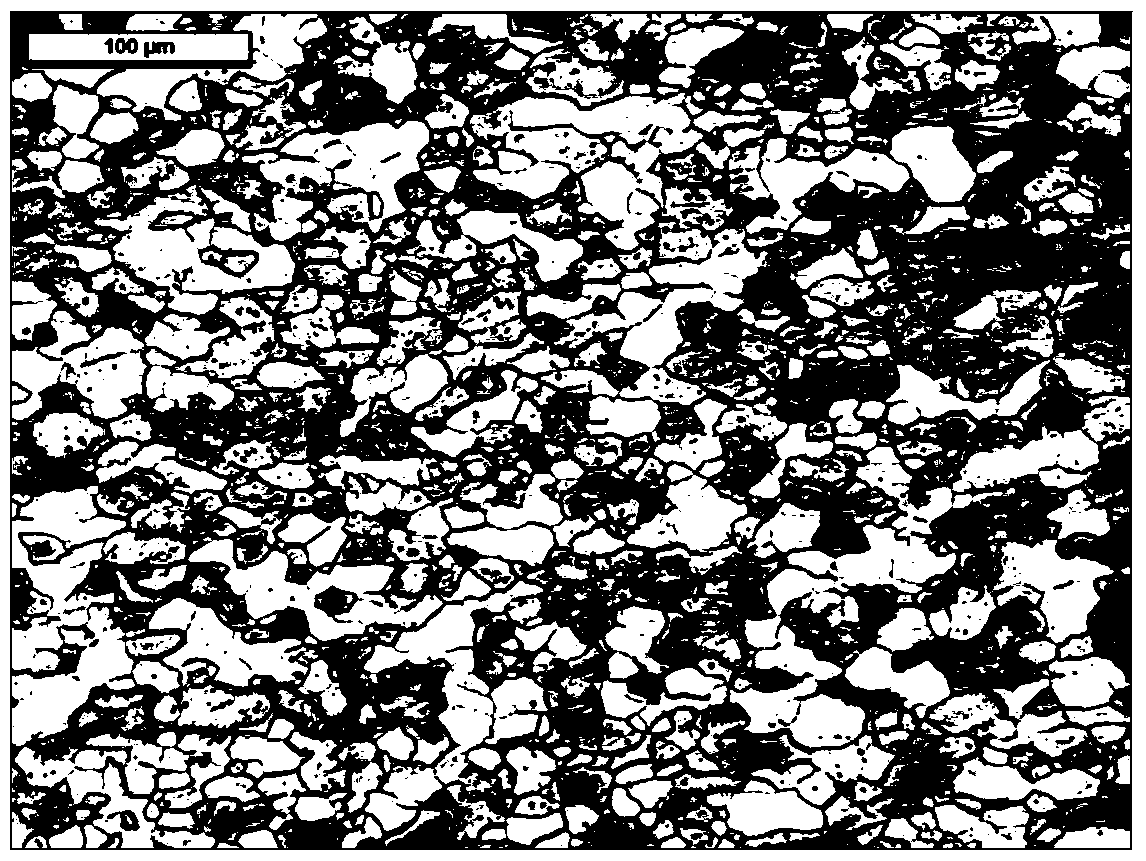

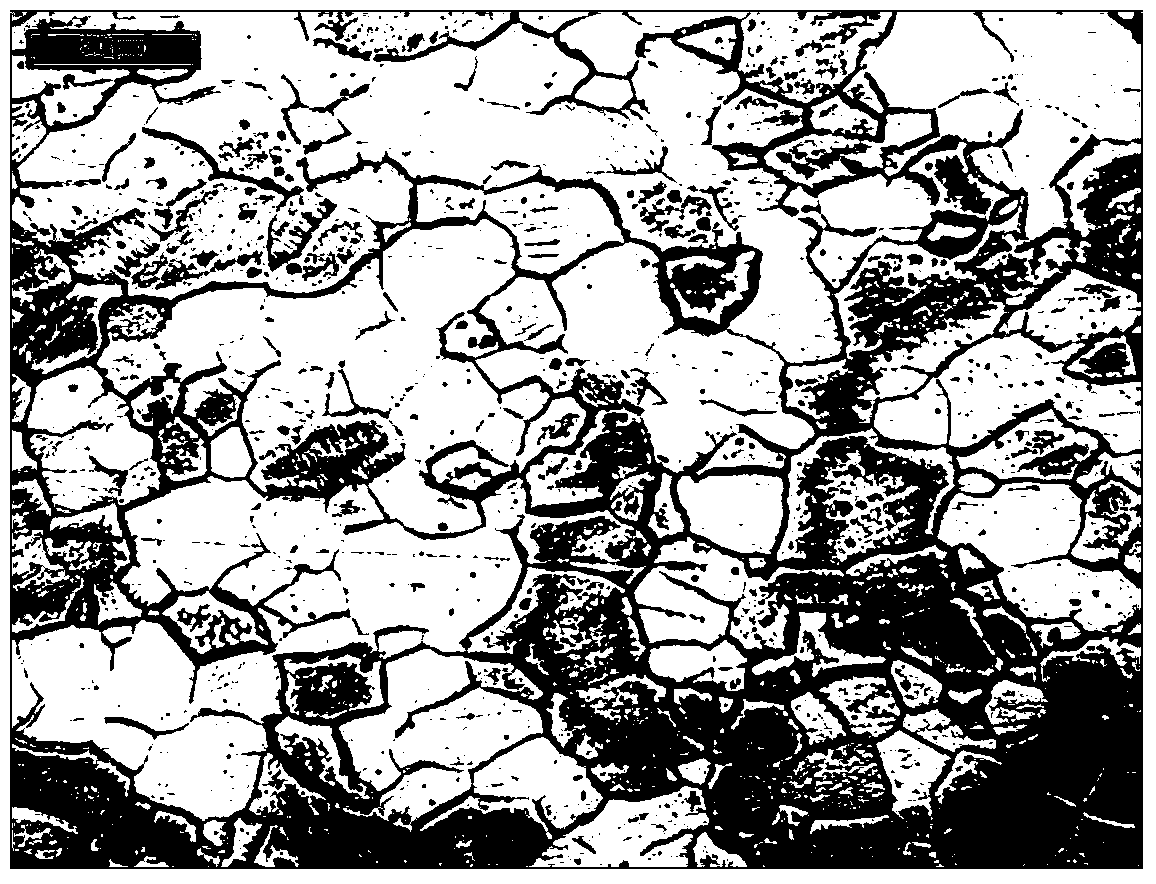

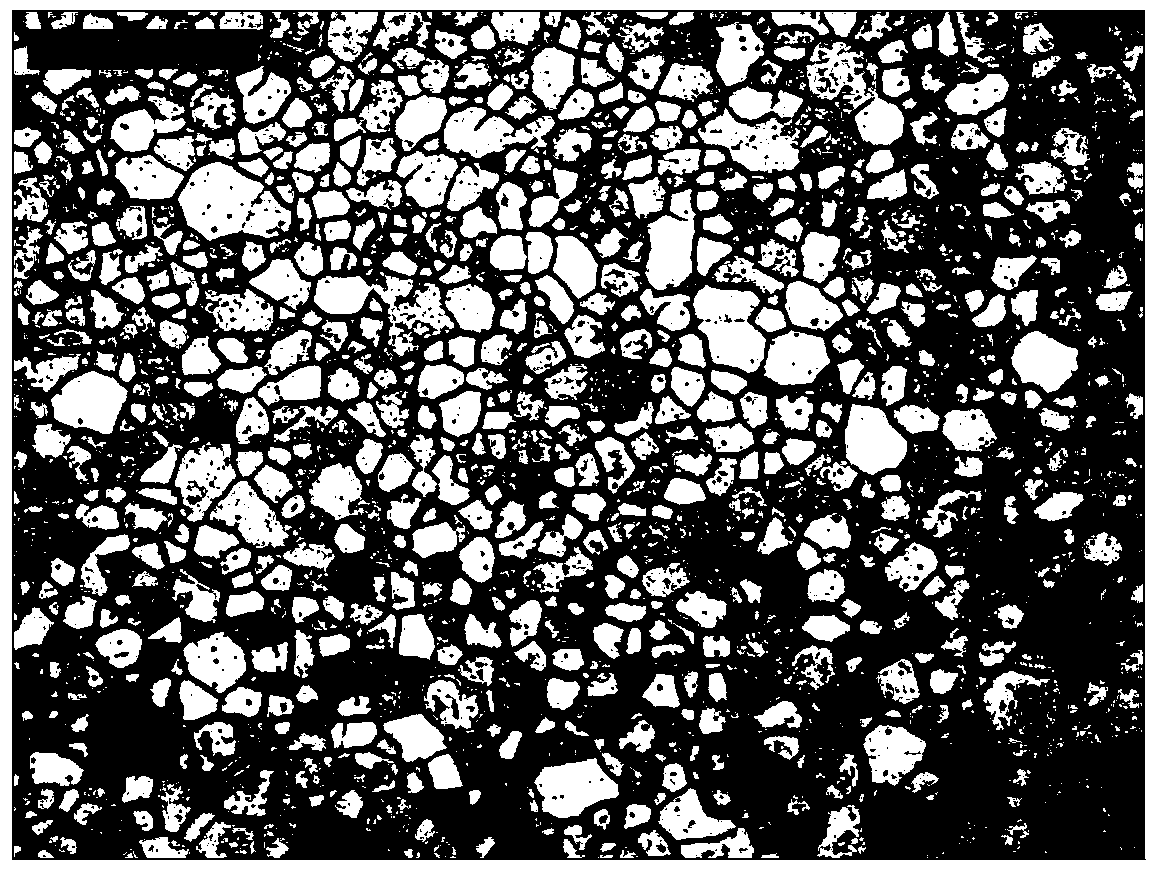

Method for displaying ultralow carbon IF (Interstitial-Free) sheet metallographic structure

A technology of metallographic structure and display method, which is applied in the field of metallographic inspection, can solve the problems that ferrite grain boundaries cannot be clearly displayed, and achieve the effects of easy embossment of grain boundaries, low cost, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Experiment 1 Preparation of metallographic samples of IF thin plate with carbon content of 0.0014% (mass percentage) and display of ferrite structure.

[0021] The steps for the preparation of the metallographic sample and the display of the ferrite structure are as follows:

[0022] 1) Mounting: Open the mounting machine, put 12g mounting powder in the mounting chamber, insert the IF steel thin plate sample into the mounted powder, cover the mounting machine cover, pressurize, set the mounting time as 3 minutes to cool The time is 2 minutes, after cooling, take out the mounted sample.

[0023] 2) Grinding: Grind the inlaid samples on water sandpaper, and the order of sandpaper grinding is No. 150, No. 300, No. 600 and No. 800. When grinding, make sure to rinse with water before changing each sandpaper and remove the wear marks of the previous sandpaper, and pay attention that the whole sample should be parallel to the top and bottom, and the same plane cannot be worn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com