A ball screw pair reliability test device

A ball screw pair and test device technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of lack of versatility, short test stroke, narrow application range, etc., to achieve good market prospects, strong versatility, Reasonable effect of mechanical structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

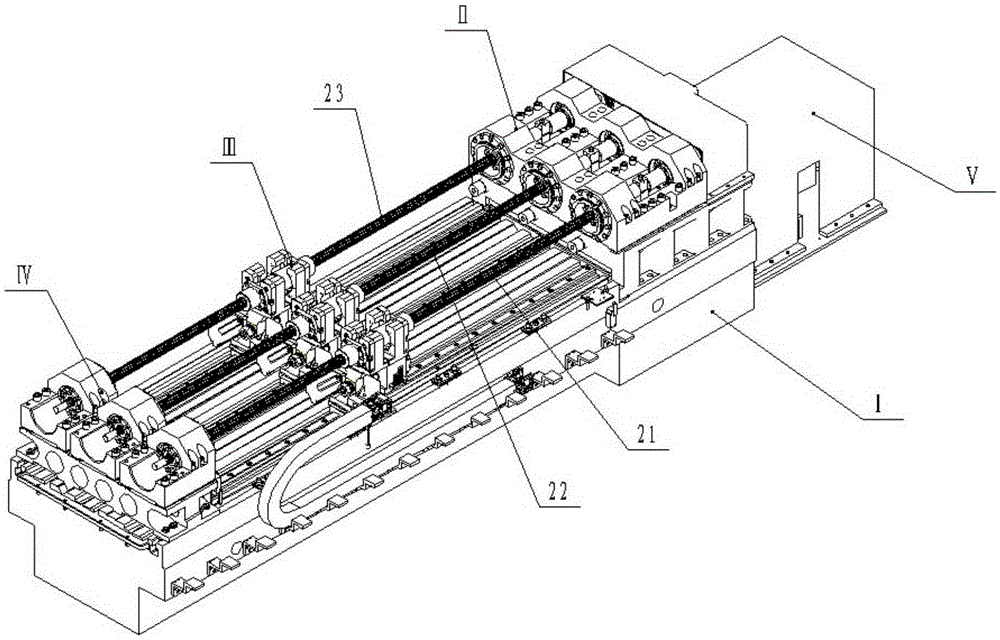

[0025] to combine figure 1 , a reliability test device for a ball screw pair of the present invention, comprising a bed part I, a test bench headstock part II, a loading part III, a tailstock part IV and a driving part V; the driving part V is located in the bed part I The headstock part II of the test bench is located on the side of the upper surface of the bed part I close to the driving part V, the tailstock part IV is located on the side of the upper surface of the bed part I away from the driving part V, and the loading part III is located on the side of the bed part I above and between the headstock part II and the tailstock part IV of the test bench, the loading part III can reciprocate relative to the bed part I driven by the drive part V;

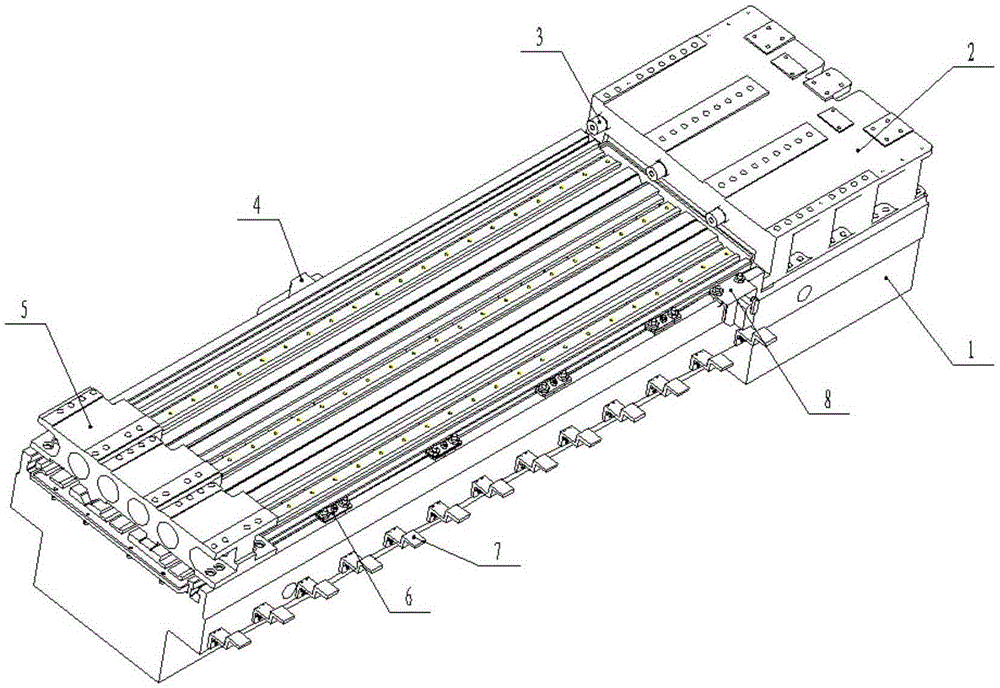

[0026] to combine figure 2 , the bed part I includes a bed 1, a headstock support plate 2, an anti-collision block 3, a lubrication pump 4, a tailstock support plate 5, a proximity switch 6, a tank chain bracket 7 and a limit swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com