Axial nut loading mechanism for ball screen assemblies

A ball screw pair, axial loading technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of easy oil leakage, difficult to clean, troublesome structural design, etc., to avoid hydraulic oil leakage, easy processing, structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

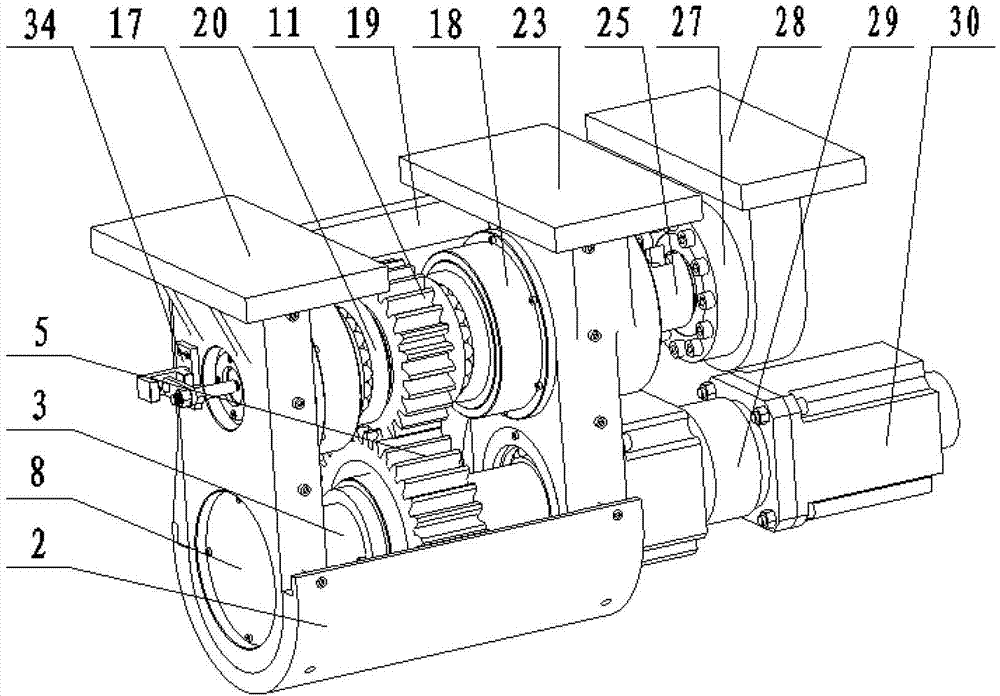

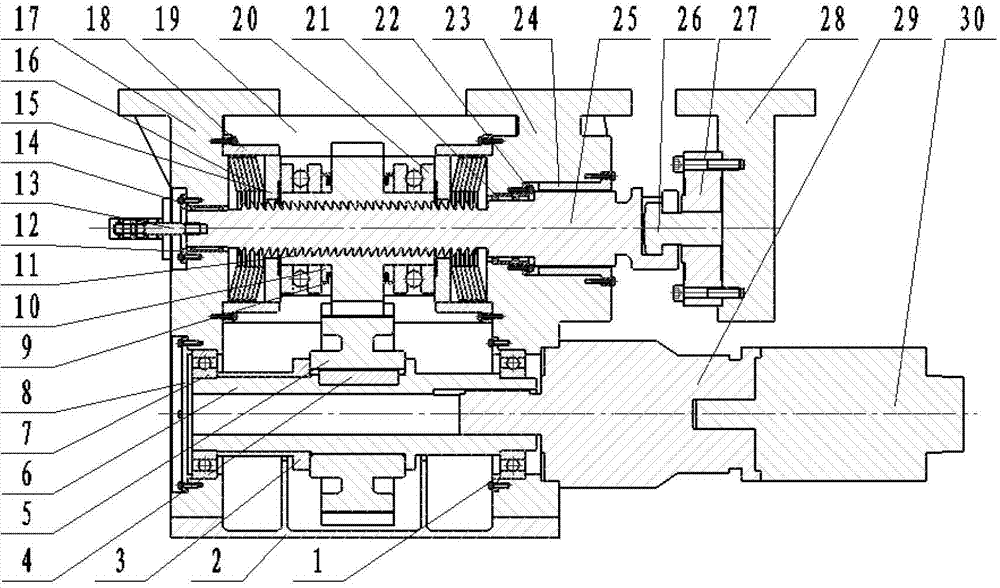

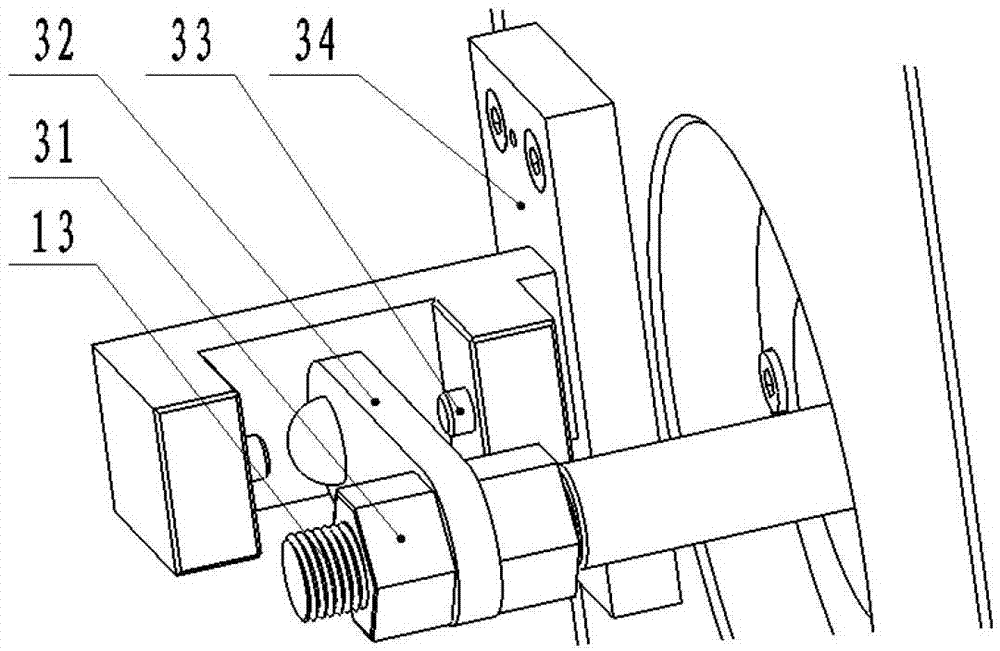

[0022] A ball screw sub-nut axial loading mechanism of the present invention includes a driving assembly, a loading assembly, a limiting assembly, and a measuring assembly;

[0023] The drive assembly includes a servo motor 30 and a reducer 29, a driving shaft 6, a positioning key 4, a driving gear 5, a positioning sleeve 3, a deep groove ball bearing 7, a sealing end cover 8, and a positioning end cover 1; The output shaft is connected with the reducer 29, the output shaft of the reducer 29 is connected with the driving shaft 6 through a key, and the driving shaft 6 is installed between the left hanging arm 17 and the right hanging arm 23 of the loading assembly through the deep groove ball bearing 7, and the deep groove The ball bearing 7 is axially positioned through the sealing end cover 8 and the positioning end cover 1 respectively, and the driving shaft 6 is fixedly connected with the driving gear 5 through the positioning key 4, and the driving gear 5 is axially positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com